Abstract

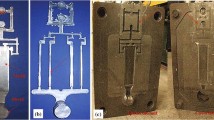

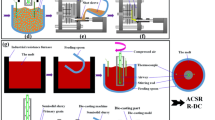

The influence of amplitude and frequency of die vibration during solidification on microstructural evolution of Al–7Si–0.2Mg (356, LM-25) alloy was studied. The amplitude of die vibration was varied from 0.0 to 1.05 mm at 50 Hz frequency, and the frequency was changed from 30 to 50 Hz at a amplitude of 0.75 mm. Structural examination and quality of the casting were evaluated in terms of porosity at various processing conditions. Vibration modified and refined structure during gravity die casting of the alloy. Macrostructure of casting prepared in vibrating die consisted of fine equiaxed grains. In contrast, macrostructure of casting produced in stationary die typically consisted of columnar grains at the periphery and equiaxed grains at the center. Die vibration resulted in microstructure of mixed type comprising of globular and dendritic primary α-Al with interdendritic eutectic Si particles. On the contrary, microstructure of casting produced in stationary die consisted of dendritic α-Al structure and eutectic Si particles. In addition, die vibration reduced secondary dendritic arms spacing (SDAS) to 18.98 μm from 34.38 μm obtained without vibration. Since SDAS is a measure of cooling rate, its reduction due to die vibration implies an increase in cooling rate of casting. This is attributed to the forced convection effect generated by die vibration. Consequently, the higher cooling rate owing to the die vibration reduced microsegregation of Si and Mg in the casting. Further, structural modification and refinement due to die vibration improved the quality of casting significantly in terms of porosity.

Similar content being viewed by others

References

J.G. Kaufman, E.L. Rooy, Aluminum Alloy Castings: Properties, Processes, and Applications (ASM International, Materials Park, 2004)

W.S. Miller, L. Zhuang, J. Bottema, A.J. Wittebrood, P.D. Smet, A. Haszler, A.I. Vieregge, Mater. Sci. Eng. A 280, 37 (2000)

D.R. Gunasegaram, D.J. Farnsworth, T.T. Nguyen, J. Mater. Process. Technol. 209, 1209 (2009)

T. Triyono, N. Muhayat, A. Supriyanto, L. Lutiyatmi, Arch. Foundry Eng. 17, 227 (2017)

M. Mostafaei, M. Ghobadi, E.B. Ghasem, M. Uludag, M. Tiryakioglu, Metall. Mater. Trans. 47B, 3469 (2016)

M. Javidani, D. Larouche, Int. Mater. Rev. 59, 132 (2014)

M. Di Sabatino, L. Arnberg, Trans. Indian Inst. Metals 62, 321 (2009)

F. Stadler, H. Antrekowitsch, W. Fragner, H. Kaufmann, E.R. Pinatel, P.J. Uggowitzer, Mater. Sci. Eng. A 560, 481 (2013)

N. Roy, A. Samuel, F. Samuel, Metall. Trans. A 27, 415 (1996)

J.F. Major, AFS Trans. 105, 901 (1997)

S.B. Kim, Y.H. Cho, J.G. Jung, W.H. Yoon, Y.K. Lee, J.M. Lee, Metals Mater. Int. 24, 1376 (2018)

W. Khalifa, Y. Tsunekawa, M. Okumiya, Int. J. Cast Metals Res. 21, 129 (2008)

Y. Mizutani, S. Kawai, K. Miwa, K. Yasue, T. Tamura, Mater. Trans. 45, 1939 (2004)

J. Dong, J. Cui, X. Zeng, W. Ding, Mater. Lett. 59, 1502 (2005)

K. Girija, I. Satyanarayana, Int. J. Adv. Res. Manag. Archit. Technol. Eng. 1, 21 (2015)

S. Kumar, S.P. Tewari, Sadhana 41, 1203 (2016)

S. Kumar, S.P. Tewari, Inter Metalcast 12, 28 (2018). https://doi.org/10.1007/s40962-017-0135-x

P.N. Anyalebechi, Inter Foundry Res. 63, 32 (2011)

M.C. Mehta, D. Mandal, S.K. Chaudhury, Inter Metalcast 13, 438 (2019). https://doi.org/10.1007/s40962-018-0271-y

J. Campbell, Advances in the Science and Engineering of Casting Solidification (Springer, Cham, 2015), p. 357

J. Deshpande, M.M. Makhlouf, AFS Trans. 116, 1–18 (2008)

ASTM Standard E3-11, vol. 03.01 (ASTM International, West Conshohocken, PA, 2017)

T. Tamura, T. Matsuki, K. Miwa, Light Metals (2011), p. 827

Y. Yoshitake, K. Yamamoto, N. Sasaguri, H. Era, Inter Metalcast 13, 553 (2019). https://doi.org/10.1007/s40962-018-0289-1

C. Allen, Q. Han, Inter Metalcast 5, 69 (2011). https://doi.org/10.1007/BF03355511

L.Y. Pio, S. Sulaiman, A.M. Hamouda, M.M.H.M. Ahmad, J. Mater. Process. Technol. 162–163, 435 (2005)

A. Claro, J. Conrads, J. Fava, R.A. Flinn, AFS Trans. 78, 324 (1970)

M.A. Suarez, I. Figueroa, A. Cruz, A. Hernandez, J.F. Chavez, Mater. Res. 15, 763 (2012)

T. Timelli, E.D. Corte, F. Bonollo, Mater. Sci. Forum 678, 105 (2011)

A.B. Michael, M.B. Bever, J. Metals 6, 47 (1954)

L. Pedersen, L. Arnberg, Mater. Sci. Eng. A 241, 285 (1998)

A.R. Valizadeh, A.R. Kiani-Rashid, M.H. Avazkonandeh-Gharoval, E.Z. Karimi, Metallogr. Microstruct. Anal. 2, 107 (2013)

D.M. Levine, D.F. Stephan, T.C. Krehbiel, M.L. Berenson, Statistics for Managers Using Microsoft® Excel (Prentice Hall, Upper Saddle River, 2008)

W. Chen, S. Wu, R. Wang, Inter Metalcast 13, 969 (2019). https://doi.org/10.1007/s40962-019-00319-y

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mehta, M.C., Mandal, D. & Chaudhury, S.K. Microstructural Changes and Quality Improvement of Al7Si0.2Mg (356) Alloy by Die Vibration. Inter Metalcast 14, 987–998 (2020). https://doi.org/10.1007/s40962-020-00408-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-020-00408-3