Abstract

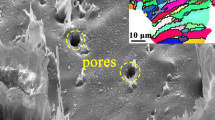

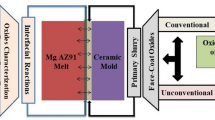

The main objective of the present research is to develop a technique to inhibit the mould–metal interaction in the investment casting of magnesium (Mg) alloys. The use of yttria layers (Y2O3) as an interface mould coating to manufacture thin-walled samples of AZ91D-1 wt% CaO alloy was investigated and the reaction mechanisms were exploited. Additive manufacturing models with thin walls (2 mm thick) were designed to study the casting behaviour of the melt in ceramic moulds (plaster), for both coated and uncoated models. Additionally, the optimal processing parameters were taken into account using a vacuum induction furnace under a flowing argon atmosphere to prevent the ignition of the molten Mg. Regarding uncoated models tests, a considerable content of reaction products was revealed, resulting in large defects all over the castings. In these samples, new phases have been formed around the surface and the matrix due to the mould–metal reactions. On the other hand, the interaction between the liquid metal and the plaster was prevented in those ceramic moulds where yttria was used as an interface protective refractory, which led to a cleaner surface and a more uniform microstructure, improving the effectiveness of this process in the manufacture of Mg structures.

Similar content being viewed by others

References

F. Pan, M. Chen, J. Wang, J. Peng, A. Tang, Effects of yttrium addition on microstructure and mechanical properties of as-extruded AZ31 magnesium alloys. Trans. Nonferrous Met. Soc. China 18, s1–s6 (2008)

Jiangxi Provincial Engineering Research Center for Magnesium alloys, GanNan Normal University, Ganzhou 341000, PR China and B. Han, Preparation of yttrium-based rare earth conversion coating and its effect on corrosion resistance of AZ91D magnesium alloy, Int. J. Electrochem. Sci. pp. 374–385, (2017)

G. Arruebarrena et al., Development of investment-casting process of Mg-alloys for aerospace applications. Adv. Eng. Mater. 9(9), 751–756 (2007)

E. Piyush, R. Raghu, M.S. Rakesh, S.G. Sriram, Magnesium alloy casting technology for automotive applications—a review. Int. Res. J. Eng. Tech. 4(10) (2017)

F. Pan, M. Yang, X. Chen, a review on casting magnesium alloys: modification of commercial alloys and development of new alloys. J. Mater. Sci. Technol. 32(12), 1211–1221 (2016)

A. Elsayed, E. Vandersluis, S. Lun Sin, C. Ravindran, Inclusions in permanent mold cast magnesium ZE41A and AZ91D alloys. Int. J. Met. 11(4), 749–765 (2017)

L. Wang, R. Lett, S. Felicelli, J. Berry, J. Jordon, D. Penrod, Microstructure and performance of four casting processes for magnesium alloy AZ91. Int. J. Met. 5(4), 37–46 (2011)

G.A. Lara-Rodriguez, I.A. Figueroa, M.A. Suarez, O. Novelo-Peralta, I. Alfonso, R. Goodall, A replication-casting device for manufacturing open-cell Mg foams. J. Mater. Process. Technol. 243, 16–22 (2017)

A. Kucharczyk, K. Naplocha, J.W. Kaczmar, H. Dieringa, K.U. Kainer, Current status and recent developments in porous magnesium fabrication. Adv. Eng. Mater. 20(1), 1700562 (2018)

I.L. Lehr, S.B. Saidman, Corrosion protection of AZ91D magnesium alloy by a cerium-molybdenum coating. The effect of citric acid as an additive (J. Magnes, Alloys, 2018)

G. Yuan, G. You, S. Bai, W. Guo, Effects of heat treatment on the thermal properties of AZ91D magnesium alloys in different casting processes. J. Alloys Compd. 766, 410–416 (2018)

S. Pattnaik, D.B. Karunakar, P.K. Jha, Developments in investment casting process—a review. J. Mater. Process. Technol. 212(11), 2332–2348 (2012)

A. Kumar, S. Kumar, N.K. Mukhopadhyay, Introduction to magnesium alloy processing technology and development of low-cost stir casting process for magnesium alloy and its composites. J. Magnes. Alloys 6(3), 245–254 (2018)

T. Wang, S. Yao, W. Shen, A submerged-gate casting method. J. Mater. Process. Technol. 222, 21–26 (2015)

S. Lun Sin, D. Dubé, R. Tremblay, An investigation on microstructural and mechanical properties of solid mould investment casting of AZ91D magnesium alloy. Mater. Charact. 59(2), 178–187 (2008)

H. Jafari, M.H. Idris, A. Ourdjini, A review of ceramic shell investment casting of magnesium alloys and mold-metal reaction suppression. Mater. Manuf. Process. 28(8), 843–856 (2013)

S.L. Sin, D. Dubé, R. Tremblay, Interfacial reactions between AZ91D magnesium alloy and plaster mould material during investment casting. Mater. Sci. Technol. 22(12), 1456–1463 (2006)

Z. Zhang, G. Morin, Effect of inhibitor gas on mould–magnesium reactions in investment casting, in Magnesium Technology 2004, ed. by A.A. Luo (The Minerals, Metals & Society, 2004), pp. 197–202

H. Jafari, M.H. Idris, A. Ourdjini, An alternative approach in ceramic shell investment casting of AZ91D magnesium alloy: in situ melting technique. J. Mater. Process. Technol. 214(4), 988–997 (2014)

J.J. Barbosa, C.S. Ribeiro, Influence of crucible material on the level of contamination in TiAl using induction melting. Int. J. Cast Met. Res. 12(5), 293–301 (2000)

F. Gomes, H. Puga, J. Barbosa, C.S. Ribeiro, Effect of melting pressure and superheating on chemical composition and contamination of Yttria-coated ceramic crucible induction melted titanium alloys. J. Mater. Sci. 46(14), 4922–4936 (2011)

B.D. Lee, U.H. Beak, K.W. Lee, G.S. Han, J.W. Han, Protective properties of SF6 under various carrier gases for the protection of molten Mg. Mater. Trans. 54(1), 66–73 (2013)

W. Ha, Y.-J. Kim, Effects of cover gases on melt protection of Mg alloys. J. Alloys Compd. 422(1–2), 208–213 (2006)

S.K. Kim, Design and development of high-performance eco-mg alloys, in Magnesium Alloys-Design, Processing and Properties, ed. by F. Czerwinski (IntechOpen, 2011)

S.K. Kim, Proportional strength-ductility relationship of non-SF6 diecast AZ91D eco-Mg alloys, in Magnesium Technology 2011, ed. by W.H. Sillekens, S.R. Agnew, N.R. Neelameggham, S.N. Mathaudhu (Springer, Cham, 2011), pp. 131–136

A.K. Bihari, M. Ramachandram, V. Kumar, Effect of process parameters on roughness and hardness of surface and dimensional accuracy of lost wax process casting. J. Mater. Sci. Eng. 4(175) (2015)

X. Li, W. Yu, J. Wang, S. Xiong, Influence of melt flow in the gating system on microstructure and mechanical properties of high pressure die casting AZ91D magnesium alloy. Mater. Sci. Eng., A 736, 219–227 (2018)

T. Phetrattanarangsi et al., The behavior of gypsum-bonded investment in the gold jewelry casting process. Thermochim. Acta 657, 144–150 (2017)

H. Jafari, M.H. Idris, A. Ourdjini, M.R. Abdul Kadir, An investigation on interfacial reaction between in situ melted AZ91D magnesium alloy and ceramic shell mold during investment casting process. Mater. Chem. Phys. 138(2–3), 672–681 (2013)

M.E. Moussa, M.A. Waly, A.M. El-Sheikh, Effect of Ca addition on modification of primary Mg2Si, hardness and wear behavior in Mg–Si hypereutectic alloys. J. Magnes. Alloys 2(3), 230–238 (2014)

M. Lotfpour, M. Emamy, C. Dehghanian, B. Pourbahari, Ca addition effects on the microstructure, tensile and corrosion properties of Mg matrix alloy containing 8 wt% Mg2Si. J. Mater. Eng. Perform. 27(2), 411–422 (2018)

F. Czerwinski, The oxidation behaviour of an AZ91D magnesium alloy at high temperatures. Acta Mater. 50(10), 2639–2654 (2002)

H. Jafari, M.H. Idris, A. Ourdjini, High temperature oxidation of AZ91D magnesium alloy granule during in situ melting. Corros. Sci. 53(2), 655–663 (2011)

Acknowledgements

This work was supported by national funds through FCT—Portuguese Foundation for Science and Technology on the aim of the research doctoral Grant SFRH/BD/129223/2017 and by FEDER funds through the COMPETE program with the reference Project PTDC/SEM-TEC/3827/2014. Additionally, this work is supported by FCT with the reference Project UID/EEA/04436/2019.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lopes, V., Puga, H., Barbosa, J. et al. Effect of Yttria Mould Coating on the Investment Casting of AZ91D-1 wt% CaO Magnesium Alloy. Inter Metalcast 14, 98–107 (2020). https://doi.org/10.1007/s40962-019-00339-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-019-00339-8