Abstract

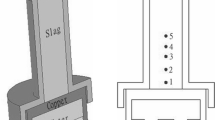

The use of steelmaking slag without chemical modification presents a deleterious effect on cement mechanical properties, due to the expansion caused by the presence of free CaO and MgO in the slag. This work deals with the modification of one basic oxygen furnace (BOF) slag with the objective of making it an appropriate additive in blended cement formulations. Two different modified slags were produced in a pilot-scale metallurgical reactor by mixing additives into 300 kg of remelted BOF slag. The liquid slags were cooled under two conditions: naturally (inside the reactor) and in contact with stainless steel balls. Quantitative X-ray diffraction and energy-dispersive spectroscopy, as well as qualitative scanning electron microscopy and Raman spectroscopy analyses of slag samples, revealed the relationship among cooling conditions and crystalline phases. The modified slags had CaO/SiO2 between 1.8 and 2.0, which is lower than the 3.8 for steelmaking slag. This reduced basicity resulted in the presence of dicalcium silicates (C2S) in higher amounts than in the steelmaking slag. β-Ca2SiO4, α′-Ca2SiO4, bredigite, and RO (FeO–MgO–MnO–CaO solid solution) were detected as major crystalline phases by X-ray diffraction and Raman spectroscopy. Cement samples were produced by mixing 25 wt% of modified steelmaking slag with 75 wt% of ordinary Portland cement, resulting in expansion lower than 0.1% in the autoclave tests and compressive strength higher than 40 MPa after 28 days. Cement samples produced by adding modified slags presented expansions 5 times lower than that determined for cement samples produced by adding steelmaking slag without any modification. The process indicates potential to be applied as a steelmaking slag treatment.

Similar content being viewed by others

References

Bréad P (2016) Brazil-economic revival in latin America’s largest economy—global economics. http://www.gbm.scotiabank.com/English/bns_econ/latin.pdf. Accessed 26 Nov 2016

Instituto Aço Brasil (2016) http://www.acobrasil.org.br/site2015/estatisticas.asp. Accessed Nov 2016

Belhadj E, Diliberto C, Lecomte A (2012) Characterization and activation of basic oxygen furnace slag. Cem Concr Compos 34:34–40

Faraone N, Tonello G, Furlani E, Maschio S (2009) Steelmaking slag as aggregate for mortars: effects of particle dimension on compression strength. Chemosphere 77:1152–1156

Li JX, Yu QJ, Wei JX, Zhang TS (2011) Structural characteristics and hydration kinetics of modified steel slag. Cem Concr Res 41:324–329

Tossavainen M, Engstrom F, Yang Q, Menad N, Larsson ML, Bjorkman B (2007) Characteristic of steel slag under different cooling conditions. Waste Manag 27:1335–1344

Ferreira Neto JB, Faria JOG, Fredericci C, Chotolli FF, Silva ANL, Ferraro BB, Ribeiro TR, Malynowskyj A, Qarcioni VA, Lotto AA (2016) Modification of molten steelmaking slag for cement application. J Sustain Metall 2(1):13–27

Kriskova L, Pontikes Y, Pandelaers L, Cizer O, Jones PT, van Balen K, Blanpain B (2013) Effect of high cooling rates on the mineralogy and hydraulic properties of stainless steel slags. Metall Trans B 44:1173–1184

Qian GR, Sun DD, Tay JH, Lai ZY (2002) Hydrothermal reaction and autoclave stability of Mg bearing RO phase in steel slag. Br Ceram Trans 101(4):159–164

Li Z, Zhou Z, Cheng X (2011) Effect of temperature on the present forms of MgO in the reconstruction of steel slag. Adv Mat Lett 2(3):206–209

Tantawy MA (2014) Low temperature synthesis of belite cement from white sand and lime. Int J Eng Res Technol 3(10):1351–1355

Chan CJ, Kriven WM, Young JF (1992) Physical stabilization of α-β transformation in dicalcium silicate. J Am Ceram Soc 75(6):1621–1627

Gautier M, Poirier J, Bodenan F, Franceschini G, Véron E (2013) Basic oxygen furnace (BOF) slag cooling: laboratory characteristics and prediction calculations. Int J Miner Process 123:94–101

Solvi M, Greiveldinger B, Hoffmann M, Friederici C, Michels D (2013) Granulation of metallurgical slag. US 2013/0292878 A1

Kappes H, Michels D (2015) Dry slag granulation and energy recovery. In: Proceedings of the Fourth International Slag Valorization Symposium. Leuven, pp 39–52

ASTM E 246-10—Determination of iron by dichromate titrimetry (2015) In: Volume 03.05 - Analytical Chemistry for Metals, Ores, and Related Materials: E 32 - latest

Xu Z, Hwang J, Greenlund R, Huang X, Luo J, Anschuetz S (2003) Quantitative determination of metallic iron content in steel-making slag. J Miner Mater Charact Eng 2(1):65–70

Thibeau RJ, Brown CW, Heidersbach RH (1978) Raman spectra of possible corrosion products of iron. Appl Spectrosc 32(6):532–535

de Faria DLA, Silva SV, de Oliveira MT (1997) Raman microspectroscopy of some iron oxides and oxyhydroxides. J Raman Spectrosc 28(11):873–878

Jung SS, Sohn II (2013) Effect of FeO concentration on the crystallization of high-temperature CaO-Al2O3-MgO-FeO melts. J Am Ceram Soc 96(4):1309–1316

Shi CJ (2004) Steel slag—its production, processing, characteristics and cementitious properties. J Mater Civil Eng 16(3):230–236

Murphy JN, Meadowcroft TR, Barr PV (1997) Enhancement of the cementitious properties of steelmaking slag. Can Metall Q 36(5):315–331

Stephan D, Wilhelm P (2004) Synthesis of pure cementitious phases by sol-gel process as precursor. Z Anorg Allg Chem 630:1477–1483

Lafuente B, Downs RT, Yang H, Stone N (2015) The power of databases: the RRUFF project. In: Armbruster T, Danisi RM, (eds) Highlights in mineralogical crystallography. Berlin, Germany, W. De Gruyter, pp 1–30. http://rruff.info/. Accessed 26 Nov 2016

Remy C, Reynard B, Madom M (1997) Raman spectroscopic investigation of dicalcium silicate: polymorphs and high-temperatures phase transformation. J Am Ceram Soc 80(2):413–423

Sharma SK, Simons B, Yoder HS (1983) Raman study of anorthite, calcium Tschermak Pyroxene, and gehlenite in crystalline and glassy states. Am Miner 68(11):1113–1125

Demoulin A, Trigance C, Neff D, Foy E, Dillmann P, L’Hostis V (2010) The evolution of the corrosion of iron in hydraulic binders analysed from 46- and 260-year-old buildings. Corros Sci 52(10):3168–3179

Wang A, Kuebler KE, Jolliff BL, Haskin LA (2004) Raman spectroscopy of Fe-Ti-Cr oxides, case study: Martian meteorite EETA79001. Am Miner 89:665–680

Wesselsky A, Jensen OM (2009) Synthesis of pure Portland cement phases. Cem Concr Res 39:973–980

Acknowledgements

The authors gratefully acknowledge the financial support from InterCement and Embrapii.

Author information

Authors and Affiliations

Corresponding author

Additional information

The contributing editor for this article was Il Sohn.

Rights and permissions

About this article

Cite this article

Ferreira Neto, J.B., Fredericci, C., Faria, J.O.G. et al. Modification of Basic Oxygen Furnace Slag for Cement Manufacturing. J. Sustain. Metall. 3, 720–728 (2017). https://doi.org/10.1007/s40831-017-0133-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-017-0133-5