Abstract

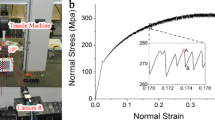

We propose a novel scanner-based digital image correlation (DIC) method to determine the full-field in-plane displacement as well as the Young’s modulus of elastomeric materials at strains up to 350%. A low-cost charged-couple device flatbed scannerwas used as the image acquisition device instead of a digital camera in the conventional DIC method. A motorized loading fixture was designed to act as the specimen clamp as well as the tensile load applicator. The rubber specimens weremade according to the ASTM:D412-06a standard andmounted into the fixture. Each specimen was scanned at increasing loads and the images were processed to obtain the full-field displacement maps using incremental cross-correlation algorithm. The Young’s modulus of the rubber at strains of 50–350% obtained using the scanner-based DIC method was compared with those obtained from a universal tensile test machine. The comparison shows a maximum deviation in Young’s modulus of 8.9 at 150% strain. The high-resolution flatbed scanner coupled with the built-in lighting was found to be an effective tool for low-cost DIC application for large deformation materials.

Similar content being viewed by others

References

Passieux, J.-C., Bugarin, F., David, C., Périé, J.-N., and Robert, L., “Multiscale Displacement Field Measurement Using Digital Image Correlation: Application to the Identification of Elastic Properties,” Experimental Mechanics 55: 121–137 (2015).

Ahn, B., and Nutt, S.R., “Strain Mapping of Al–Mg Alloy with Multi-scale Grain Structure Using Digital Image Correlation Method,” Experimental Mechanics 50: 117–123 (2010).

Chen, J.L., Zhan, N., Zhang, X.C., and Wang, J.X., “Improved Extended Digital Image Correlation for Crack Tip Deformation Measurement,” Optics and Lasers in Engineering 65: 103–109 (2015).

Tang, Z.Z., Liang, J., Xiao, Z.Z., and Guo, C., “Large Deformation Measurement Scheme for 3D Digital Image Correlation Method,” Optics and Lasers in Engineering 50: 122–130 (2012).

Laraba-Abbes, F., Ienny, P., and Piques, R., “A New ‘tailor-made’ Methodology for the Mechanical Behaviour Analysis of Rubber-like Materials: I. Kinematics Measurements Using a Digital Speckle Extensometry,” Polymer 44: 807–820 (2003).

Laraba-Abbes, F., Ienny, P., and Piques, R., “A New ‘tailor-made’ Methodology for the Mechanical Behaviour Analysis of Rubber-like Materials: II. Application to the Hyperelastic Behaviour Characterization of a Carbon-black Filled Natural Rubber Vulcanizate,” Polymer 44: 821–840 (2003).

de Crevoisier, J., Besnard, G., Merckel, Y., et al., “Volume Changes in a Filled Elastomer Studied via Digital Image Correlation,” Polymer Testing 31: 663–670 (2012).

Pan, B., Wu, D.F., and Xia, Y., “Incremental Calculation for Large Deformation Measurement Using Reliability-guided Digital Image Correlation,” Optics and Lasers in Engineering 50: 586–592 (2012).

Jerabek, M., Major, Z., and Lang, R.W., “Strain Determination of Polymeric Materials Using Digital Image Correlation,” Polymer Testing 29: 407–416 (2010).

Kangasrääsiö, J., and Hemming, B., “Calibration of a Flatbed Scanner for Traceable Paper Area Measurement,” Measurement Science and Technology 20: 107003 (2009).

Kee, C.W., and Ratnam, M.M., “A Simple Approach to Fine Wire Diameter Measurement Using a High-resolution Flatbed Scanner,” The International Journal of Advanced Manufacturing Technology 40: 940–947 (2008).

Korin, I., Larrainzar, C., and Ipinã, J.P., “Crack Length and Stable Crack Extension Measurements from Images Acquired by Means of a Conventional Flatbed Scanner,” Fatigue & Fracture of Engineering Materials & Structures 30: 876–884 (2008).

Lim, T.Y., and Ratnam, M.M., “Edge Detection and Measurement of Nose Radii of Cutting Tool Inserts from Scanned 2-D Images,” Optics and Lasers in Engineering 50: 1628–1642 (2012).

Ng, T.W., and Tajuddin, A., “Shadow Moiré Topography Using a Flatbed Scanner,” Optical Engineering 41: 1908–1911 (2002).

van Dalen, G., “Determination of the Size Distribution and Percentage of Broken Kernels of Rice Using Flatbed Scanning and Image Analysis,” Food Research International 37: 51–58 (2004).

ASTM D412-06a, Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers-Tension, ASTM International, West Conshohocken, PA (2013).

Song, S., Chen, W., and Cheng, M., “Novel Model for Uniaxial Strain-Rate–Dependent Stress– Strain Behavior of Ethylene–Propylene–Diene Monomer Rubber in Compression or Tension,” Journal of Applied Polymer Science 92: 1553–1558 (2004).

Pan, B., Qian, K.M., Xie, H.M., and Asundi, A., “Two-Dimensional Digital Image Correlation for In-plane Displacement and Strain Measurement: A Review,” Measurement Science and Technology 20: 062001 (2009).

Bornert, M., Bremand, F., Doumalin, P., et al., “Assessment of Digital Image Correlation Measurement Errors: Methodology and Results,” Experimental Mechanics 49: 353–370 (2009).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Goh, C.P., Ratnam, M.M. & Ismail, H. Large In-plane Deformation Mapping and Determination of Young’s Modulus of Rubber Using Scanner-Based Digital Image Correlation. Exp Tech 40, 1117–1127 (2016). https://doi.org/10.1007/s40799-016-0113-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40799-016-0113-x