Abstract

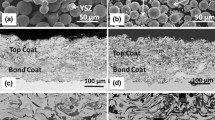

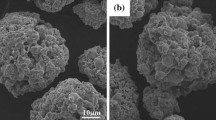

An approach of chrome carbide-based composite coating entailing of hard phase (Cr3C2–NiCr) and matrix-CoCrAlY was tailored to encounter the severe environments such as elevated temperature oxidation, corrosion and erosion in gas turbine application. CoCrAlY + Cr3C2–NiCr coating was deposited by atmospheric plasma spray process. Oxidation and hot corrosion tests were conducted under cyclic conditions in Na2SO4–V2O5 salt environment at 700 °C. The oxidation and hot corrosion behaviour base metal and coated samples were evaluated by thermogravimetric method. Scanning electron microscopy/energy-dispersive spectroscopy (SEM/EDS) and X-ray diffraction techniques were used to characterize the tested samples in terms of elemental and phase analysis. Microhardness of the composite coating is 318 ± 26 HV and the adhesion strength is found to be 11.5 ± 2.5 MPa. The uncoated alloys exhibited limited weight gain for the initial oxidation cycles followed by linear weight gain curve with the increasing in thermocycles. The CoCrAlY + Cr3C2–NiCr coating experienced good corrosion resistance as compared to substrates- MDN 321 and Superni 76 at 700 °C. The coatings subjected to oxidation and hot corrosion showed slow-scale growth kinetics with parabolic rate constant (Kp) value of 0.4 and 0.053 10–10 g2 cm−4 s−1, respectively. The higher Cr content in the coating resulted in the growth of Cr2O3 and its spinel CoCr2O4 as a strong phase is beneficial for oxidation and corrosion resistance.

Similar content being viewed by others

References

Lu J, Zhu S, Wang F (2011) High temperature corrosion behavior of an AIP NiCoCrAlY coating modified by aluminizing. Surf Coat Technol 205:5053–5058

James AW, Rajagopalan S (2014) Gas turbines: operating conditions, components and material requirements. In: Shirzadi A, Jackson S (eds) Structural alloys for power plants. Woodhead Publishing, Cambridge, pp 3–21

Miller BA (1986) Failure analysis and prevention. ASM Metals Handbook, USA

Baiamonte L, Marra F, Gazzola S, Giovanetto P, Bartuli C, Valente T, Pulci G (2016) Thermal sprayed coatings for hot corrosion protection of exhaust valves in naval diesel engines. Surf Coat Technol 295:78–87

Nicholls JR, Simms NJ, Chan WY, Evans HE (2002) Smart overlay coatings—concept and practice. Surf Coat Technol 149(2–3):236–244

Cabral-Miramontes JA, Gaona-Tiburcio C, Almeraya-Calderón F, Estupiñan-Lopez FH, Pedraza-Basulto GK, Poblano-Salas CA (2014) Parameter studies on high-velocity oxy-fuel spraying of CoNiCrAlY coatings used in the aeronautical industry. Int J Corros. https://doi.org/10.1155/2014/703806

Ramesh MR, Prakash S, Nath SK, Sapra PK, Venkataraman B (2010) Solid particle erosion of HVOF sprayed WC-Co/NiCrFeSiB coatings. Wear 269(3–4):197–205

Kim K, Korsunsky AM (2010) Dissipated energy and fretting damage in CoCrAlY-MoS2 coatings. Tribol Int 43(3):676–684

Nithin HS, Desai V, Ramesh MR (2018) Elevated temperature solid particle erosion behaviour of carbide reinforced CoCrAlY composite coatings. Mater Res Express 5(6):066529

Matthews S, Berger LM (2016) Long-term compositional/microstructural development of Cr3C2–NiCr coatings at 500 °C, 700 °C and 900 °C. Int J Refract Metal Hard Mater 59:1–8

Murthy JK, Venkataraman B (2006) Abrasive wear behaviour of WC–CoCr and Cr3C2–20 (NiCr) deposited by HVOF and detonation spray processes. Surf Coat Technol 200(8):2642–2652

Zhou W, Zhou K, Deng C, Zeng K, Li Y (2017) Hot corrosion behavior of HVOF-sprayed Cr3C2-WC-NiCoCrMo coating. Ceram Int 43(12):9390–9400

Seo D, Ogawa K, Suzuki Y, Ichimura K, Shoji T, Murata S (2008) Comparative study on oxidation behavior of selected MCrAlY coatings by elemental concentration profile analysis. Appl Surf Sci 255(5):2581–2590

Zhou W, Zhou K, Deng C, Zeng K, Li Y (2017) Hot corrosion behaviour of HVOF-sprayed Cr3C2–NiCrMoNbAl coating. Surf Coat Technol 309:849–859

Nithin HS, Vijay D, Ramesh MR (2018) Cyclic oxidation and Hot Corrosion behavior of plasma-sprayed CoCrAlY+ WC-Co coating on turbine alloys. J Fail Anal Prev 18(5):1133–1142

Chatha SS, Sidhu HS, Sidhu BS (2012) High temperature hot corrosion behaviour of NiCr and Cr3C2–NiCr coatings on T91 boiler steel in an aggressive environment at 750 °C. Surf Coat Technol 206(19–20):3839–3850

Fan QX, Jiang SM, Yu HJ, Gong J, Sun C (2014) Microstructure and hot corrosion behaviors of two Co modified aluminide coatings on a Ni-based superalloy at 700 °C. Appl Surf Sci 311:214–223

Ramesh MR, Prakash S, Nath SK, Sapra PK, Krishnamurthy N (2011) Evaluation of thermocyclic oxidation behavior of HVOF-sprayed NiCrFeSiB coatings on boiler tube steels. J Therm Spray Technol 20(5):992–1000

Chatterjee UK, Bose SK, Roy SK (2001) Environmental degradation of metals: corrosion technology series, vol 14. CRC Press, Boca Raton

Yuan K, Peng RL, Li XH, Johansson S, Wang YD (2015) Some aspects of elemental behaviour in HVOF MCrAlY coatings in high-temperature oxidation. Surf Coat Technol 261:86–101

Zhang T, Huang C, Lan H, Du L, Zhang W (2016) Oxidation and hot corrosion behavior of plasma-sprayed MCrAlY–Cr 2 O 3 coatings. J Therm Spray Technol 25(6):1208–1216

Hidalgo VH, Varela FB, Menéndez AC, Martınez SP (2001) A comparative study of high-temperature erosion wear of plasma-sprayed NiCrBSiFe and WC–NiCrBSiFe coatings under simulated coal-fired boiler conditions. Tribol Int 34(3):161–169

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nithin, H.S., Nishchitha, K.M., Shamanth, V. et al. High-Temperature Oxidation and Corrosion Behaviour of APS CoCrAlY + Cr3C2–NiCr Composite Coating. J Bio Tribo Corros 6, 28 (2020). https://doi.org/10.1007/s40735-020-0322-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-020-0322-9