Abstract

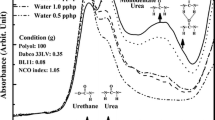

For comfortable driving conditions, flexible polyurethane (PU) foams are used for sound absorbers in noise, vibration, harshness (NVH) systems. The cellular structures of PU foams are important to improve the sound absorption efficiency, and the cell morphology is strongly dependent the use of experimental ingredients such as catalysts and cross-linking agents. Uniform cavity size distribution is achieved by controlling the catalyst ratio between gelling and blowing catalysts, and the optimum catalyst ratio (9:1) is used with a diethanolamine (DEA) cross-linker for improved sound absorption efficiency. DEA affects pore morphology by preventing phase separation in PU matrix, and the number of open pores reduces with increasing DEA contents. Sound absorption coefficient shows the highest at 9:1 catalyst ratio and 0.9 g DEA usage in the flexible PU foams under disturbed phase separation conditions.

Similar content being viewed by others

References

Zhang, C., Li, J., Hu, Z., Zhu, F., and Huang, Y., “Correlation between the Acoustic and Porous Cell Morphology of Polyurethane Foam: Effect of Interconnected Porosity,” Materials & Design, Vol. 41, pp. 319–325, 2012.

Thirumal, M., Khastgir, D., Singha, N. K., Manjunath, B., and Naik, Y., “Effect of Foam Density on the Properties of Water Blown Rigid Polyurethane Foam,” Journal of Applied Polymer Science, Vol. 108, No. 3, pp. 1810–1817, 2008.

Verdejo, R., Stämpfli, R., Alvarez-Lainez, M., Mourad, S., Rodriguez-Perez, M., et al., “Enhanced Acoustic Damping in Flexible Polyurethane Foams Filled with Carbon Nanotubes,” Composites Science and Technology, Vol. 69, No. 10, pp. 1564–1569, 2009.

Na, Y., Lancaster, J., Casali, J., and Cho, G., “Sound Absorption Coefficients of Micro-Fiber Fabrics by Reverberation Room Method,” Textile Research Journal, Vol. 77, No. 5, pp. 330–335, 2007.

Broos, R., Sonney, J., Thanh, H. P., and Casati, F., “Polyurethane Foam Molding Technologies for Improving Total Passenger Compartment Comfort,” Proc. of the Polyurethane Conference, pp. 341–353, 2000.

Imai, Y. and Asano, T., “Studies of Acoustical Absorption of Flexible Polyurethane Foam,” Journal of Applied Polymer Science, Vol. 27, No. 1, pp. 183–195, 1982.

Lyu, M.-Y. and Choi, T. G., “Research Trends in Polymer Materials for Use in Lightweight Vehicles,” Int. J. Precis. Eng. Manuf., Vol. 16, No. 1, pp. 213–220, 2015.

Dornfeld, D. A., “Moving towards Green and Sustainable Manufacturing,” Int. J. Precis. Eng. Manuf.-Green Tech., Vol. 1, No. 1, pp. 63–66, 2014.

Jang, S., Goh, C. H., and Choi, H.-J., “Multiphase Design Exploration Method for Lightweight Structural Design: Example of Vehicle Mounted Antenna-Supporting Structure,” Int. J. Precis. Eng. Manuf.-Green Tech., Vol. 2, No. 3, pp. 281–287, 2015.

Gwon, J. G., Kim, S. K., and Kim, J. H., “Sound Absorption Behavior of Flexible Polyurethane Foams with Distinct Cellular Structures,” Materials & Design, Vol. 89, pp. 448–454, 2016.

Moon, S. K., Tan, Y. E., Hwang, J., and Yoon, Y.-J., “Application of 3D Printing Technology for Designing Light-Weight Unmanned Aerial Vehicle Wing Structures,” Int. J. Precis. Eng. Manuf.-Green Tech., Vol. 1, No. 3, pp. 223–228, 2014.

Gwon, J. G., Kim, S. K., and Kim, J. H., “Development of Cell Morphologies in Manufacturing Flexible Polyurethane Urea Foams as Sound Absorption Materials,” Journal of Porous Materials, Vol. 23, No. 2, pp. 465–473, 2016.

Zhang, X., Macosko, C., Davis, H., Nikolov, A., and Wasan, D., “Role of Silicone Surfactant in Flexible Polyurethane Foam,” Journal of Colloid and Interface Science, Vol. 215, No. 2, pp. 270–279, 1999.

Gwon, J. G., Sung, G., and Kim, J. H., “Modulation of Cavities and Interconnecting Pores in Manufacturing Water Blown Flexible Poly (Urethane Urea) Foams,” Int. J. Precis. Eng. Manuf., Vol. 16, No. 11, pp. 2299–2307, 2015.

Li, W., Ryan, A. J., and Meier, I. K., “Effect of Chain Extenders on the Morphology Development in Flexible Polyurethane Foam,” Macromolecules, Vol. 35, No. 16, pp. 6306–6312, 2002.

Li, W., Ryan, A. J., and Meier, I. K., “Morphology Development via Reaction-Induced Phase Separation in Flexible Polyurethane Foam,” Macromolecules, Vol. 35, No. 13, pp. 5034–5042, 2002.

Ning, L., De-Ning, W., and Sheng-Kang, Y., “Hydrogen-Bonding Properties of Segmented Polyether Poly (Urethane Urea) Copolymer,” Macromolecules, Vol. 30, No. 15, pp. 4405–4409, 1997.

Heintz, A. M., Duffy, D. J., Nelson, C. M., Hua, Y., Hsu, S. L., et al., “A Spectroscopic Analysis of the Phase Evolution in Polyurethane Foams,” Macromolecules, Vol. 38, No. 22, pp. 9192–9199, 2005.

Ugarte, L., Saralegi, A., Fernández, R., Martín, L., Corcuera, M., et al., “Flexible Polyurethane Foams Based on 100% Renewably Sourced Polyols,” Industrial Crops and Products, Vol. 62, pp. 545–551, 2014.

Schön, P., Bagdi, K., Molnár, K., Markus, P., Pukánszky, B., et al., “Quantitative Mapping of Elastic Moduli at the Nanoscale in Phase Separated Polyurethanes by AFM,” European Polymer Journal, Vol. 47, No. 4, pp. 692–698, 2011.

Kaushiva, B. and Wilkes, G., “Alteration of Polyurea Hard Domain Morphology by Diethanol Amine (DEOA) in Molded Flexible Polyurethane Foams,” Polymer, Vol. 41, No. 18, pp. 6981–6986, 2000.

Wang, Y., Zhang, C., Ren, L., Ichchou, M., Galland, M. A., et al., “Influences of Rice Hull in Polyurethane Foam on Its Sound Absorption Characteristics,” Polymer Composites, Vol. 34, No. 11, pp. 1847–1855, 2013.

Lee, J., Kim, G. H., and Ha, C. S., “Sound Absorption Properties of Polyurethane/Nano-Silica Nanocomposite Foams,” Journal of Applied Polymer Science, Vol. 123, No. 4, pp. 2384–2390, 2012.

Kaushiva, B. D. and Wilkes, G. L., “Influence of Diethanolamine (DEOA) on Structure-Property Behavior of Molded Flexible Polyurethane Foams,” Journal of Applied Polymer Science, Vol. 77, No. 1, pp. 202–216, 2000.

Xia, H., Song, M., Zhang, Z., and Richardson, M., “Microphase Separation, Stress Relaxation, and Creep Behavior of Polyurethane Nanocomposites,” Journal of Applied Polymer Science, Vol. 103, No. 5, pp. 2992–3002, 2007.

Doutres, O., Atalla, N., and Dong, K., “Effect of the Microstructure Closed Pore Content on the Acoustic Behavior of Polyurethane Foams,” Journal of Applied Physics, Vol. 110, No. 6, Paper No. 064901, 2011.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, S.K., Sung, G., Gwon, J.G. et al. Controlled phase separation in flexible polyurethane foams with diethanolamine cross-linker for improved sound absorption efficiency. Int. J. of Precis. Eng. and Manuf.-Green Tech. 3, 367–373 (2016). https://doi.org/10.1007/s40684-016-0046-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-016-0046-y