Abstract

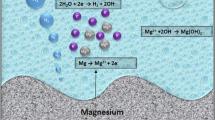

Magnesium alloys are potential biodegradable and biocompatible implant materials because of their excellent biological properties. Recently, interest in these alloys as a promising alternative for temporary orthopedic implants has grown owing to their desirable biological, mechanical, and physical properties. However, the application of magnesium alloys is hindered by their rapid degradation and low corrosion resistance in physiological fluids, leading to the failure of implants. Thus, the current challenge is to enhance the corrosion resistance and control the degradation rate of magnesium under physiological conditions. The rapid degradation of magnesium alloys can be controlled by improving their surface integrity, such as surface roughness and microhardness. The present study aims to improve the surface integrity of the Mg Ze41A alloy by the ball burnishing technique. The surface roughness improved by 94.90% from 0.941 μm to 0.048 μm with a burnishing force of 50 N, burnishing speed of 1 300 r/min, burnishing feed of 130 mm/min, and three passes. Similarly, the microhardness improved by 50.62% from 75.2 HV to 113.27 HV with a burnishing force of 60 N, burnishing speed of 1 100 r/min, burnishing feed of 100 mm/min, and five passes. The variations in microhardness, which were observed up to 400 μm beneath the surface, exhibited a linear nature. These variations may be attributed to the movement of dislocations, formation of new dislocations, nanocrystal structures, metastable phases and subgrains, and lattice distortion or grain refinement. The surface features obtained from optical images demonstrated the fundamental mechanisms involved in the ball burnishing process. The concept of burnishing maps and zones will assist in the design of the ball burnishing parameters of a material with an equivalent yield strength of 140 MPa. The significant improvement in the surface integrity of the Mg Ze41A alloy by the ball burnishing technique is expected to improve its functional performance.

Similar content being viewed by others

References

Oliver JN, Zhu D, Su Y et al (2019) Bioactive glass coatings on metallic implants for biomedical applications. Bioact Mater 4:261–270

Manam NS, Harun WSW, Shri DNA et al (2017) Study of corrosion in biocompatible metals for implants: a review. J Alloys Compd 701:698–715

Chen Q, Thouas GA (2015) Metallic implant biomaterials. Mater Sci Eng R 87:1–57

Zheng YF, Gu XN, Witte F (2014) Biodegradable metals. Mater Sci Eng R 77:1–34

Geetha M, Singh AK, Asokamani R et al (2009) Ti based biomaterials, the ultimate choice for orthopaedic implants—a review. Prog Mater Sci 54:397–425

Gu XN, Xie XH, Li N et al (2012) In vitro and in vivo studies on a Mg-Sr binary alloy system developed as a new kind of biodegradable metal. Acta Biomater 8:2360–2374

Witte F (2010) The history of biodegradable magnesium implants: a review. Acta Biomater 6(5):1680–1692

Mostaed E, Sikora-jasinska M, Drelich JW et al (2018) Zinc-based alloys for degradable vascular stent applications. Acta Biomater 71:1–23

Chen Y, Xu Z, Smith C et al (2014) Recent advances on the development of magnesium alloys for biodegradable implants. Acta Biomater 10(11):4561–4573

Yang YW, He CX, E DY et al (2020) Mg bone implant: features, developments and perspectives. Mater Des 185:108259. https://doi.org/10.1016/j.matdes.2019.108259

Wu G, Ibrahim JM, Chu PK (2013) Surface design of biodegradable magnesium alloys—a review. Surf Coatings Technol 233:2–12

Agarwal S, Curtin J, Duffy B et al (2016) Biodegradable magnesium alloys for orthopaedic applications: a review on corrosion, biocompatibility and surface modifi cations. Mater Sci Eng C 68:948–963

Zhang S, Zhang X, Zhao C et al (2010) Research on an Mg-Zn alloy as a degradable biomaterial. Acta Biomater 6:626–640

Witte F, Kaese V, Haferkamp H et al (2005) In vivo corrosion of four magnesium alloys and the associated bone response. Biomaterials 26:3557–3563

Thomas S, Medhekar NV, Frankel GS et al (2015) Corrosion mechanism and hydrogen evolution on Mg. Curr Opin Solid State Mater Sci 19:85–94

Pu Z, Song GL, Yang S et al (2012) Grain refined and basal textured surface produced by burnishing for improved corrosion performance of AZ31B Mg alloy. Corros Sci 57:192–201

Jagadeesh GV, Gangi Setti S (2021) Bio-engineering and bio-design of new generation bioresorbable implants. Indian J Biochem Biophys 58:118–126

Liu D, Yang D, Li X et al (2018) Mechanical properties, corrosion resistance and biocompatibilities of degradable Mg-RE alloys: a review. J Mater Res Technol 8(1):1538–1549

Asri RIM, Harun WSW, Samykano M et al (2017) Corrosion and surface modification on biocompatible metals: a review. Mater Sci Eng C 77:1261–1274

Pan HC, Ren YP, Fu H et al (2016) Recent developments in rare-earth free wrought magnesium alloys having high strength: a review. J Alloys Compd 663:321–331

Salahshoor M, Guo YB (2011) Surface integrity of biodegradable magnesium-calcium orthopedic implant by burnishing. J Mech Behav Biomed Mater 4(8):1888–1904

Jerez-Mesa R, Fargas G, Roa JJ et al (2021) Superficial effects of ball burnishing on trip steel AiSi 301LN sheets. Metals 11(1):1–12

Nguyen TT, Cao LH (2020) Optimization of the burnishing process for energy responses and surface properties. Int J Precis Eng Manuf 21(6):1143–1152

Hamadache H, Zemouri Z, Laouar L et al (2014) Improvement of surface conditions of 36 Cr Ni Mo 6 steel by ball burnishing process. J Mech Sci Technol 28(4):1491–1498

Gharbi F, Sghaier S, Al-Fadhalah KJ et al (2011) Effect of ball burnishing process on the surface quality and microstructure properties of AISI 1010 steel plates. J Mater Eng Perform 20(6):903–910

Ravindra BP, Ankamma K, Siva PT et al (2011) Effects of burnishing parameters on the surface characteristics, microstructure and microhardness in EN series steels. Trans Indian Inst Met 64(6):565–573

Rotella G, Rinaldi S, Filice L (2020) Roller burnishing of Ti6Al4V under different cooling/lubrication conditions and tool design: effects on surface integrity. Int J Adv Manuf Techno 106(1/2):431–440

Rotella G, Filice L, Micari F (2020) Improving surface integrity of additively manufactured GP1 stainless steel by roller burnishing. CIRP Ann 69(1):513–516

Banh QN, Shiou FJ (2016) Determination of optimal small ball-burnishing parameters for both surface roughness and superficial hardness improvement of STAVAX. Arab J Sci Eng 41(2):639–652

Revankar GD, Shetty R, Rao SS et al (2014) Analysis of surface roughness and hardness in ball burnishing of titanium alloy. Measurement 58:256–268

Yuan X, Sun Y, Li C et al (2017) Experimental investigation into the effect of low plasticity burnishing parameters on the surface integrity of TA2. Int J Adv Manuf Technol 88(1/4):1089–1099

Revankar GD, Shetty R, Rao SS et al (2014) Selection of optimal process parameters in ball burnishing of titanium alloy. Mach Sci Technol 18(3):464–483

Sequera A, Fu CH, Guo YB et al (2014) Surface integrity of Inconel 718 by ball burnishing. J Mater Eng Perform 23(9):3347–3353

Amdouni H, Bouzaiene H, Montagne A et al (2017) Modeling and optimization of a ball-burnished aluminum alloy flat surface with a crossed strategy based on response surface methodology. Int J Adv Manuf Technol 88(1/4):801–814

Yuan XL, Sun YW, Gao LS et al (2016) Effect of roller burnishing process parameters on the surface roughness and microhardness for TA2 alloy. Int J Adv Manuf Technol 85(5/8):1373–1383

Pang C, Luo H, Zhang Z et al (2017) Precipitation behavior and grain refinement of burnishing Al-Zn-Mg alloy. Prog Nat Sci Mater Int 28:54–59

Shiou FJ, Banh QN (2016) Development of an innovative small ball-burnishing tool embedded with a load cell. Int J Adv Manuf Technol 87(1/4):31–41

Jagadeesh GV, Gangi Setti S (2020) A current status of the residual stress characterization by the crystal lattice strain (diffraction) method. J Struct Chem 61(2):262–273

Rodríguez A, López de Lacalle LN, Celaya A et al (2012) Surface improvement of shafts by the deep ball-burnishing technique. Surf Coatings Technol 206(11/12):2817–2824

Stalin JMR, Balaji B, Vinayagam BK (2017) Optimisation of internal roller burnishing process in CNC machining center using response surface methodology. J Brazilian Soc Mech Sci Eng 39(10):4045–4057

Salahshoor M, Guo YB (2013) Process mechanics in ball burnishing biomedical magnesium-calcium alloy. Int J Adv Manuf Technol 64(1/4):133–144

Buldum BB, Cagan SC (2018) Study of ball burnishing process on the surface roughness and microhardness of AZ91D alloy. Exp Tech 42(2):233–241

Silva-Álvarez DF, Márquez-Herrera A, Saldaa-Robles A et al (2020) Improving the surface integrity of the CoCrMo alloy by the ball burnishing technique. J Mater Res Technol 9(4):7592–7601

Uddin M, Hall C, Santos V et al (2021) Synergistic effect of deep ball burnishing and HA coating on surface integrity, corrosion and immune response of biodegradable AZ31B Mg alloys. Mater Sci Eng C 118:111459. https://doi.org/10.1016/j.msec.2020.111459

Salahshoor M, Li C, Liu ZY et al (2018) Surface integrity and corrosion performance of biomedical magnesium-calcium alloy processed by hybrid dry cutting-finish burnishing. J Mech Behav Biomed Mater 78:246–253

Jagadeesh GV, Setti SG (2019) An experimental study on the surface finish of ball burnished magnesium (rare earth base) alloy. Mater Today Proc 18:4711–4716

Gomez-Gras G, Travieso-Rodriguez JA, Jerez-Mesa R et al (2016) Experimental study of lateral pass width in conventional and vibrations-assisted ball burnishing. Int J Adv Manuf Technol 87(1/4):363–371

Egala R, Jagadeesh GV, Setti SG (2021) Experimental investigation and prediction of tribological behavior of unidirectional short castor oil fiber reinforced epoxy composites. Friction 9(2):250–272

Travieso-Rodriguez HGRJA, Gomez GG, Jorba PJ et al (2015) Experimental study on the mechanical effects of the vibration-assisted ball- burnishing process. Mater Manuf Process 30(12):1490–1497

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jagadeesh, G.V., Gangi Setti, S. Surface integrity of ball burnished bioresorbable magnesium alloy. Adv. Manuf. 11, 342–362 (2023). https://doi.org/10.1007/s40436-021-00387-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40436-021-00387-6