Abstract

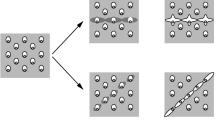

This paper is concerned with prediction of the damage evolution and fracture of DP590 by exploring a new semi-coupled ductile fracture criterion. The new semi-coupled ductile fracture criterion uses the DF2010 ductile fracture criterion as the initial damage model with modifying the original fracture strain \({\overline{\varepsilon }}_{f}^{p}\) to the initial damage strain \({\overline{\varepsilon }}_{i}^{p}\) in the model. In order to further describe the softening phenomenon after damage, this model introduces a damage variable D to measure the cumulative damage and couples the damage variable D to the plastic model to construct a damage evolution model. In order to verify the semi-coupled ductile fracture criterion, the fracture experiment of DP590 was carried out. The resistance method was used to measure the initial damage and fracture of the sample, and the DIC technique was used to measure the strain distribution on the surface of the sample. The initial damage model and damage evolution parameters were calibrated using the experiment–simulation hybrid method and the reverse analysis method, respectively. The VUMAT user subroutine of the calibrated semi-coupled model is implemented into ABAQUS and used to simulate the stretching of each sample. The results show that the semi-coupled ductile fracture criterion can accurately predict the fracture behavior of DP590 materials under different stress states and describe the damage-induced softening phenomenon during the forming process of DP590.

Similar content being viewed by others

Abbreviations

- \({c}_{1}, {c}_{2}, {c}_{3}\) :

-

Material-related parameters

- A, m:

-

Fitting coefficient of the hardening model

- n:

-

Hardening index

- K:

-

Hardening coefficient

- \(w\) :

-

Weight coefficient in the linear combination hardening model.

- \({q}_{1},{q}_{2}\) :

-

Calibration parameters of GTN model

- \(v_{i}\) :

-

Initial damage displacement

- \(\mathrm{L}\) :

-

Lode parameter

- \(\eta\) :

-

Stress triaxiality.

- D:

-

Damage variable

- \({D}_{0}\) :

-

Internal variable (The damage process remains inactivated)

- \(\dot{D}\) :

-

Damage evolution rate

- \({G}_{f}\) :

-

Energy required to open a crack per unit area

- \({L}_{e}\) :

-

Characteristic length related to the integral point

- Dcr:

-

Critical value of damage accumulation

- \({{\varvec{C}}}^{{\prime}}, {{\varvec{C}}}^{{\prime}}{\prime}\) :

-

Matrix of anisotropic coefficients

- T :

-

Transformation matrix

- \(\bar{\sigma }_{{eq}}\) :

-

Yield stress

- \(\bar{\sigma }\left( {\bar{\varepsilon }} \right),\bar{\sigma }\) :

-

Flow stress

- \({\sigma }_{0}\) :

-

Initial yield strength

- \({\sigma }_{y0}\) :

-

Yield stress value at the beginning of the damage

- \({\varvec{\sigma}}\) :

-

Cauchy stress tensor

- \({\varepsilon }_{0}\) :

-

Pre-strain

- Δε:

-

Equivalent plastic strain increment

- \({\dot{\varepsilon }}^{p}\) :

-

Equivalent plastic strain rate

- \({\overline{\varepsilon }}^{p}\) :

-

Equivalent plastic strain

- \({\overline{\varepsilon }}_{i}^{p}\) :

-

Initial damage strain

- \({\overline{\varepsilon }}_{f}^{p}\) :

-

Original fracture strain

- \({\sigma }_{0 }, {\sigma }_{45}, {\sigma }_{90}, {r}_{0}, {r}_{45}, {r}_{90}, {\sigma }_{b}, {r}_{b}\) :

-

Calibration parameters of yield function

- DIC:

-

Digital image correlation

- MMC:

-

Modified Mohr–Coulomb damage criterion

- GTN:

-

Gurson–Tvergaard–Needleman model

- CDM:

-

Continuum damage mechanics

- DF2012:

-

Lou’s fracture criterion

- \({\overline{S} }^{\mathbf{^{\prime}}},\boldsymbol{ }{\overline{S} }^{\mathbf{^{\prime}}\mathbf{^{\prime}}},\boldsymbol{ }{\mathrm{L}}^{^{\prime}}, {\mathrm{L}}^{{^{\prime}}{^{\prime}}}, {\mathrm{L}}_{2}^{\mathbf{^{\prime}}\mathbf{^{\prime}}}\) :

-

Stress tensors

References

Huang Jianguo (2015) Development and application of advanced high strength steel for automobile. Bengang Technol (3):26–31

Dai Q, Kelly J, Elgowainy A (2016) Vehicle materials: material composition of US light-duty vehicles. Energy Syst Div Argonne Natl Labs Chic. USA, 1–30

Cockcroft MG, Latham DJ (1968) Ductility and the workability of metals. J Inst Met 96:33–39

Brozzo P, Deluca B, Rendina R (1972). A new method for the prediction of formability limits in metal sheets, sheet metal forming and formability. In: Proceedings of the 7th biennial conference of the IDDRG

Oh SI, Chen CC, Kobayashi S (1979) Ductile fracture in axisymmetric extrusion and drawing-part 2: workability in extrusion and drawing. J Engng Ind 101(1):36–44

Oyane M, Sato T, Okimoto K, Shima S (1980) Criteria for ductile fracture and their applications. J Mech Work Technol 4:65–81

Bao Y, Wierzbicki T (2004) On fracture locus in the equivalent strain and stress triaxiality space. Int J Mech Sci 46(1):81–98

Bao Y, Wierzbicki T (2005) On the cut-off value of negative triaxiality for fracture. Eng Fract Mech 72(7):1049–1069

Bai Y, Wierzbicki T (2008) A new model of metal plasticity and fracture with pressure and Lode dependence. Int J Plast 24(6):1071–1096

Bai Y, Wierzbicki T (2010) Application of extended Mohr-Coulomb criterion to ductile fracture. Int J Fract 161(1):1–20

Khan AS, Liu H (2012) A new approach for ductile fracture prediction on Al 2024–T351 alloy. Int J Plast 35(8):1–12

Khan AS, Liu H (2012) Strain rate and temperature dependent fracture criteria for isotropic and anisotropic metals. Int J Plast 37(1):15

Liu HS, Fu MW (2014) Prediction and analysis of ductile fracture in sheet metal forming—Part I: A modified Ayada criterion. Int J Damage Mech 23(8):1189–1210

Mcclintock FA (1968) A Criterion for Ductile Fracture by the Growth of Holes. J Appl Mech 35(2):363–371

Rice JR, Tracey DM (1969) On the ductile enlargement of voids in triaxial stress fields. J Mech Phys Solids 17(3):201–217

Lou Y, Huh H, Lim S et al (2012) New ductile fracture criterion for prediction of fracture forming limit diagrams of sheet metals. Int J Solids Struct 49(25):3605–3615

Brünig M, Gerke S, Hagenbrock V (2014) Stress-state-dependence of damage strain rate tensors caused by growth and coalescence of micro-defects. Int J Plast 63:49–63

Lou Y, Yoon JW, Huh H (2014) Modeling of shear ductile fracture considering a changeable cut-off value for stress triaxiality. Int J Plast 54(1):56–80

Cao TS, Gachet JM, Montmitonnet P (2014) A Lode-dependent enhanced Lemaitre model for ductile fracture prediction at low stress triaxiality. Eng Fract Mech 124:80–96

Gurson AL (1977) Continuum theory of ductile rupture by void nucleation and growth: part I-yield criteria and flow rules for porous ductile media. J Eng Mater Technol 99(1):2–15

Tvergaard V (1982) On localization in ductile materials containing spherical voids. Int J Fract 18(4):237–252

Tvergaard V, Needleman A (1984) Analysis of the cup-cone fracture in a round tensile bar. Acta Metall 32(1):157–169

Needleman A, Tvergaard V (1987) An analysis of ductile rupture modes at a crack tip. J Mech Phys Solids 35(2):151–183

Chen Z, Dong X (2009) The GTN damage model based on Hill’48 anisotropic yield criterion and its application in sheet metal forming. Comput Mater Sci 44(3):1013–1021

Kim J, Gao X, Srivatsan TS (2004) Modeling of void growth in ductile solids: effects of stress triaxiality and initial porosity. Eng Fract Mech 71(3):379–400

Xue L (2008) Constitutive modeling of void shearing effect in ductile fracture of porous materials. Eng Fract Mech 75(11):3343–3366

Nahshon K, Hutchinson JW (2008) Modification of the Gurson model for shear failure. Eur J Mech A-Solid 27(1):1–17

Nielsen K, Tvergaard V (2010) Ductile shear failure or plug failure of spot welds modelled by modified Gurson model. Eng Fract Mech 77(7):1031–1047

Gatea S, Ou H, Lu B, McCartney G (2017) Modelling of ductile fracture in single point incremental forming using a modified GTN model. Eng Fract Mech 186:59–79

Davaze V, Vallino N, Feld-Payet S, Langrand B, Besson J (2020) Plastic and fracture behavior of a dual phase steel sheet under quasi-static and dynamic loadings. Eng Fract Mech 235:107165

Han M, Li D, Sun C, Li Y, Jiangning, Xu J (2020) Research on fracture failure criterion of dual-phase steel based on modified GTN model. J Plast Eng, 27(01):117-122

Kachanov LM (1958) Time of the rupture process under creep conditions. IVZ Acad. Nauk S S R Old Tech Nauk 8:26–31

Lemaitre J (1985) A continuous damage mechanics model for ductile fracture. J Eng Mater Technol 107(107):83–89

Lemaitre J (1996) A course on damage mechanics. Springer-Verlag, Berlin

Chaboche JL (1981) Continuous damage mechanics-A tool to describe phenomena before crack initiation. Nucl Eng Des 64(2):233–247

Chaboche J (1998) Continuum damage mechanics: Part I – general concepts. J Appl Mech 55:59–64

Chaboche J (1998) Continuum damage mechanics: Part II – damage growth, crack initiation, and crack growth. J Appl Mech 55:65–72

Brünig M (2003) An anisotropic ductile damage model based on irreversible thermodynamics. Int J Plast 19(10):1679–1713

Brünig M (2003) Numerical analysis of anisotropic ductile continuum damage. Comput Method Appl M 192(26):2949–2976

Brünig M (2006) Continuum framework for the rate-dependent behavior of anisotropically damaged ductile metals. Acta Mech 186(1–4):37

Dhar S, Sethuraman R, Dixit PM (1996) A continuum damage mechanics model for void growth and micro crack initiation. Eng Fract Mech 53(53):917–928

Bonora N (1997) A nonlinear CDM model for ductile failure. Eng Fract Mech 58(1):11–28

Wang TJ (1992) Unified CDM model and local criterion for ductile fracture—I Unified CDM model for ductile fracture. Eng Fract Mech 42(1):177–183

Niazi MS, Wisselink HH, Meinders T (2012) Failure predictions for dp steel cross-die test using anisotropic damage. Int J Damage Mech 21(5):713–754

Niazi MS, Wisselink HH, Meinders VT et al (2013) Material-induced anisotropic damage in DP600. Int J Damage Mech 22:1039–1070

Li Y, Wierzbicki T (2010) Prediction of plane strain fracture of AHSS sheets with post-initiation softening. Int J Solids Struct 47(17):2316–2327

Lian J, Sharaf M, Archie F, Münstermann S (2013) A hybrid approach for modelling of plasticity and failure behaviour of advanced high-strength steel sheets. Int J Damage Mech 22(2):188–218

Lian J, Wu J, Münstermann S (2015) Evaluation of the cold formability of high-strength low-alloy steel plates with the modified Bai-Wierzbicki damage model. Int J Damage Mech 24(3):383–417

Münstermann S, Lian J, Pütz F, Könemann M, Brinnel V (2017) Comparative study on damage evolution during sheet metal forming of steels dp600 and dp1000. J Phy Conf Series IOP Publish, 896(1): 012074

Zhu Y, Kiran R, Ji X (2019) A modified micromechanics framework to predict shear involved ductile fracture in structural steels at intermediate and low-stress triaxialities. Eng Fract Mech 225:106860

Kiran R, Khandelwal K (2014) A triaxiality and Lode parameter dependent ductile fracture criterion. Eng Fract Mech 128:121–138

Astm I. ASTM E8/E8M-16a (2016): Standard Test Methods for Tension Testing of Metallic Materials. West Conshohocken, PA, USA: ASTM International

Lou Y, Huh H (2013) Prediction of ductile fracture for advanced high strength steel with a new criterion: Experiments and simulation. J Mater Process Technol 213(8):1284–1302

Munstermann S (2006) Numerische Beschreibung des duktilen Versagensverhaltens von hochfesten Baustahlen unter Berucksichtigung der Mikrostruktur. PhD Thesis, RWTH Aachen University

Zhang S, Xia Q, Li W, Zhou X (2014) Ductile damage measurement and necking analysis of metal sheets based on digital image correlation and direct current potential drop methods. Int J Damage Mech 23(8):1133–1149

Lou Y, Zhang S, Yoon JW (2019) A reduced Yld 2004 function for modeling of anisotropic plastic deformation of metals under triaxial loading. Int J Mech Sci 161:105027

Ha J, Baral M, Korkolis YP (2018) Plastic anisotropy and ductile fracture of bake-hardened AA6013 aluminum sheet. Int J Solids Struct 155:123–139

Tasan CC, Hoefnagels JPM, Ten Horn CHLJ, Geers MGD (2009) Experimental analysis of strain path dependent ductile damage mechanics and forming limits. Mech Mater 41(11):1264–1276

Lou Y, Huh H (2013) Extension of a shear-controlled ductile fracture model considering the stress triaxiality and the Lode parameter. Int J Solids Struct 50(2):447–455

Hillerborg A, Modéer M, Petersson PE (1976) Analysis of crack formation and crack growth in concrete by means of fracture mechanics and finite elements. Cem Concr Res 6(6):773–781

Li H, Fu MW, Lu J, Yang H (2011) Ductile fracture: experiments and computations. Int J Plast 27(2):147–180

Hosford WF, Caddell RM (2011) Metal forming: mechanics and metallurgy. Cambridge University Press, Cambridge

Acknowledgements

This project was supported by the Guangdong National Natural Science Foundation [Grant No. 2021A1515010598].

Funding

This study was funded by Natural Science Foundation of Guangdong Province, 2021A1515010598, Saijun Zhang.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: João Marciano Laredo dos Reis.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, S., Ding, W., Li, K. et al. Prediction of ductile fracture for DP590 high-strength steel with a new semi-coupled ductile fracture criterion. J Braz. Soc. Mech. Sci. Eng. 44, 17 (2022). https://doi.org/10.1007/s40430-021-03275-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-021-03275-z