Abstract

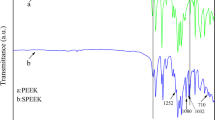

Octyl(triphenylethynyl)silane monomer(OTPES) was synthesized with ethyl bromide, octyltrichlorosilane and phenylethylene by Grignard reaction. The molecular structure was confirmed by FTIR and NMR. The poly[octyl(triphenylethynyl)]silane resin(POTPES) was prepared by thermal polymerization and the corresponding thermal degradation behavior wasstudied by thermogravimetric analysis(TG) combining with model and model-free fitted methods. The dielectric property of resin was also studied by vector network analyzer. The results show that the melt point of OTPES was 50 °C and the processing window was over 236 °C. The resin degradation temperature of Td5 occurred over 433 °C and the char yield was over 60% at 800 °C. Based on Kissinger, Flynn-Wall-Ozawa, Coats-Redfern, Achar, Vyazovkin-Wight and Tang methods, the reaction activity(E) was 155.51, 152.97, 150.82, 146.02, 148.38 and 148.77 kJ/mol, respectively. Dielectric properties analysis displayed that the real part(ε′) and the imaginary part(ε″) of the relative complex permittivity of POTPES was 2.5 and 0.05, respectively, and the dielectric loss tangent was between 0.03 and 0.25. The reflection loss of resin was more than −2.85 dB in all range of 1–5 mm thicknesses and 2–18 GHz frequency, which indicated that POTPES resin was a real wave-transparent resin matrix.

Similar content being viewed by others

References

Dhanalakshmi J. P., Raj M. A., Vijayakumar C. T., Chinese J. Polym. Sci., 2016, 34, 253

Wunderlich B., Basics of Thermal Analysis(2nd Ed.), Springer, Berlin, New York, 2005

Vyazovkin S., Sbirrazzuoli N., Macromol. Rapid Commun., 2006, 27, 1515

Balart R., Garcia D., Quiles L., Polymers, 2019, 11, 281

Guo J., Wang J., Wu Y., He Y., Song H., Chen X., Polym. Eng. Sci., 2019, 59, 246

Li H., Fu Y., Liu H., Sun C., Li R., Song L., Yang A., J. Polym. Eng., 2019, 39, 105

Melissaris A. P., Litt M. H., Macromolecules, 1994, 27, 2675

Zhou Q., Feng X., Ni L., J. Appl. Polym. Sci., 2006, 102, 2488

Tan D., Shi T. Li Z., Res. Chem. Intermed., 2011, 37, 831

Cai M., Yuan Q., Huang F., Int Polym.., 2018, 67, 1563

Wrackmeyer B., Khan E., Bayer S., Z. Naturforsch B., 2010, 65, 725

Itoh M., Inoue K., Iwata K., Adv. Mater., 1997, 9, 1187

Sellers K. W., Towns C. M., Mubarak C. R., J. Anal. Appl. Pyrolysis, 2002, 64, 313

Zhang J., Huang J., Du W., Polym. Degrad. Stab., 2011, 96, 2276

Guo K., Li P., Zhu Y., Polym. Degrad. Stab., 2016, 131, 98

Kuroki S., Kakigano K. O., Ishikawa J., Itoh M., Macromolecules, 1998, 31, 2804

Ren Y., Cheng B., Zhang J., Chem. Res. Chinese Universities, 2008, 24(5), 628

Askari F., Barikani M., Barmar M., Iran. Polym. J., 2015, 24, 783

Tang W., Liu Y., Zhang H., Wang C., Thermochimica Acta, 2003, 408, 39

Chen Y., You X., Deng S., J. Mater. Sci. Chem. Eng., 2018, 7, 1

Acknowledgments

This work was supported by the Overseas Scholarship Program for Elite Young and Middle-aged Teachers of Lingnan Normal University, China and the Research Center for Clean Energy Materials Chemical Engineering Technology of Guangdong Province, China.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by the Natural Science Foundation of Guangdong Province, China(No.2017A030307028), the Special Fund for Science and Technology Innovation Strategy of Guangdong Province, China(No.2018A01005), the Yangfan Plan of Guangdong Province, China(No.0003017011) and the Research Initiation Foundation of the Lingnan Normal University, China(Nos.ZL1604, ZL1822).

Rights and permissions

About this article

Cite this article

Wang, Y., Tan, D. Synthesis, Thermal Degradation and Dielectric Properties of Poly[octyl(triphenylethynyl)]silane Resin. Chem. Res. Chin. Univ. 35, 1076–1081 (2019). https://doi.org/10.1007/s40242-019-9170-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40242-019-9170-x