Abstract

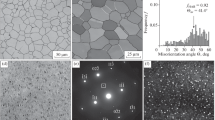

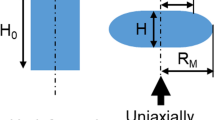

The effects of CEC passes, isothermal holding time and reheating temperature on the microstructure evolution and grain coarsening behaviour of AZ61 magnesium alloy produced by the recrystallisation and partialmelting (RAP) process were investigated. Before partial remelting, as-cast AZ61 alloy was deformed by cyclic extrusion compression (CEC) with one pass and two pass at 330 °C. After CEC, the microstructure consisted of unrecrystallized grains and deformed eutectic compounds. Increasing isothermal holding time resulted in the formation of spheroidal grains surrounded by liquid films. With increasing the isothermal holding time, the solid grain size increased and the degree of spheroidization was improved. With increasing the reheating temperature, namely increasing liquid fraction, the solid grain size obviously decreased during the period from 560 °C to 570 °C and then slightly increased after 570 °C, while the shape factor increased monotonously. During partial remelting, increasing reheating temperature can properly short the isothermal holding time to obtain fine structure. Moreover, increasing the numbers of CEC passes could produce finer semi-solid microstructure. The coarsening behavior of solid grains in the semi-solid state obeys Ostwald ripening and grain coalescence mechanisms. The coarsening rate constant, K, was 80 µm3·s−1 for samples partially remelted at 595 °C. After CEC plus partial remelting, the ideal and fine semi-solid state structure can be obtained, which was suitable for thixoforming.

Similar content being viewed by others

References

Z.D. Zhao, Q. Chen, C.K. Hu, S.H. Huang and Y.Q. Wang, J. Alloys Compd. 485 (2009) 627.

Y.J. Chen, H.J. Roven, Q.D. Wang, M.P. Liu and J.B. Lin, Mater. Sci. Forum. 584 (2008) 523.

Q. Chen, D.Y. Shu, Z.D. Zhao, Z.X. Zhao, Y.B. Wang and B.G. Yuan, Mater. Des. 40 (2012) 488.

Q. Chen, Z.W. Huang, Z.D. Zhao, C.K. Hu and D.Y. Shu, Comput. Mater. Sci. 67 (2013) 196.

Z.D. Zhao, Q. Chen, H.Y. Chao, C.K. Hu and S.H. Huang, Mater. Des. 32 (2011) 575.

X.L. Zhang, T.J. Li, H.T. Teng, S.S. Xie and J.Z. Jin, Mater. Sci. Eng. A 475 (2008) 194.

Y.J. Chen, Q.D. Wang, H.J. Roven, M. Karlsen, Y.D. Yu, M.P. Liu and J. Hjelen, J. Alloys Compd. 462 (2008) 192.

Z.D. Zhao, Q. Chen, Y.B. Wang and D.Y. Shu, Mater. Sci. Eng. A 515 (2009) 152.

J.G. Wang, H.Q. Lin, H.Y. Wang and Q.C. Jiang, J. Alloys Compd. 466 (2008) 98.

Z.D. Zhao, Q. Chen, C.K. Hu and D.Y. Shu, Mater. Des. 30 (2009) 4557.

Y.S. Cheng, Q. Chen, Z.Q. Huang and S.H. Huang, Trans. Nonferrous Met. Soc. China 20 (2010) 739.

Y. Birol, J. Alloys Compd. 461 (2008) 132.

Q. Chen, S.J. Luo and Z.D. Zhao, J. Alloys Compd. 477 (2009) 726.

Q. Chen, J. Lin, D.Y. Shu, C.K Hu, Z.D. Zhao, F. Kang, S.H. Huang and B.G. Yuan, Mater. Sci. Eng. A 554 (2012) 129.

Z.D. Zhao, Y.S. Cheng, Q. Chen, Y.B. Wang and D.Y. Shu, Trans. Nonferrous Met. Soc. China 20 (2010) 178.

E. Tzimas and A. Zavaliangos, Mater. Sci. Eng. A 289 (2000) 228.

Z.D. Zhao, Q. Chen, F. Kang and D.Y. Shu, J. Alloys Compd. 482 (2009) 455.

Z.D. Zhao, Q. Chen, Z.J. Tang, Y.B. Wang and H.Q. Ning, J. Mater. Sci. 45 (2010) 3419.

Z.D. Zhao, Q. Chen, Y.B. Wang and D.Y. Shu, Trans. Nonferrous Met. Soc. China 19 (2009) 535.

Q. Chen, Z.X. Zhao, D.Y. Shu and Z.D. Zhao, Mater. Sci. Eng. A 528 (2011) 3930.

Q.Q. Zhang, Z.Y. Cao, Y.F. Zhang, G.H. Su and Y.B. Liu, J. Mater. Proc. Technol. 184 (2007) 195.

F. Czerwinski, Scr. Mater. 48 (2003) 327.

F. Czerwinski, Acta Mater. 50 (2002) 3265.

S.J. Luo, Q. Chen, and Z.D. Zhao, Mater. Sci. Eng. A 501 (2009) 146.

J.G. Wang, P. Lu, H.Y. Wang, J.F. Liu and Q.C. Jiang, J. Alloys Compd. 395 (2005) 108.

Q. Chen, Z.D. Zhao, Z.X. Zhao, C.K. Hu and D.Y. Shu, J. Alloys Compd. 509 (2011) 7303.

Q. Chen, D.Y. Shu, C.K. Hu, Z.D. Zhao and B.G. Yuan, Mater. Sci. Eng. A 541 (2012) 98.

Y.J. Chen, Q.D. Wang, J.B Lin, L.J. Zhang and C.Q. Zhai, J. Mater. Sci. 42 (2007) 7601.

A. Azushima, R. Kopp, A. Korhonen, D.Y. Yang, F. Micari, G.D. Lahoti, P. Groche, J. Yanagimoto, N. Tsuji, A. Rosochowski and A. Yanagida, CIRP Annals-Manuf. Technol. 57 (2008) 716.

S.J. Luo, Q. Chen and Z.D. Zhao, J. Alloys Compd. 477 (2009) 602.

Z.D. Zhao, Q. Chen, H.Y. Chao and S.H. Huang, Mater. Des. 31 (2010) 1906.

L. Zhang, Y.B. Liu, Z.Y. Cao, Y.F. Zhang and Q.Q. Zhang, J. Mater. Process. Technol. 209 (2009) 792.

Z.D. Zhao, Q. Chen, Y.B. Wang and D.Y. Shu, Mater. Sci. Eng. A 506 (2009) 8.

X.H. Du and E.L. Zhang, Mater. Lett. 61 (2007) 2333.

Z.D. Zhao, Q. Chen, Z.J. Tang and C.K. Hu, J. Alloys Compd. 497 (2010) 402.

Y.J. Chen, Q.D. Wang, J.J. Peng, C.Q Zhai and W.J. Ding, J. Mater. Process. Technol. 182 (2007) 281.

Y.J. Chen, Q.D. Wang, H.J. Roven, M.P. Liu, M. Karlsen, Y.D. Yu and J. Hjelen, Scr. Mater. 58 (2008) 311.

L.J. Zhang, Q.D. Wang, Y.J Chen, J.B Lin, Mater. Sci. Forum. 546 (2007) 253.

Q.D. Wang, Y.J. Chen, M.P. Liu, J.B. Lin and H.J. Roven, Mater. Sci. Eng. A 527 (2010) 2265.

H.V. Atkinson and D. Liu, Mater. Sci. Eng. A 496 (2008) 439.

F.Y. Zhang, PhD Dissertation, University of Nanchang, Nanchang, 2008. (in Chinese)

Q. Chen, B.G. Yuan, G.Z. Zhao, D.Y. Shu, C.K. Hu, Z.D. Zhao and Z.X. Zhao, Mater. Sci. Eng. A 537 (2012) 25.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, C., Mei, H., Li, R. et al. Microstructure evolution and grain coarsening behaviour during partial remelting of cyclic extrusion compression formed AZ61 magnesium alloy. ACTA METALL SIN 26, 149–156 (2013). https://doi.org/10.1007/s40195-012-0169-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-012-0169-2