Abstract

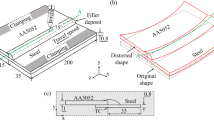

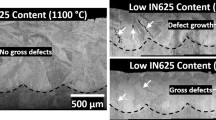

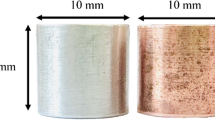

Joining of multi-metallic assemblies such as aluminum and steel sheets using fusion joining technologies is prudent although the formation of intermetallic compounds along joint interface has remained a critical challenge. An advanced, low-power input, gas metal arc process was employed here for joining of aluminum and zinc-coated steel sheets of dissimilar thicknesses in lap-joint configuration. The heat input during the process was restricted by fast responsive current and voltage pulses that allowed a synchronized arcing and short circuiting at a low arc power. The effect of heat input and thermophysical properties of base materials on the bead profile, joint strength, and distortion was studied extensively. The results indicated a rational improvement of joint quality with lowering of the heat input within a restrictive range of processing conditions such as wire feed rate and travel speed. Most importantly, the mixed-metal assembly exhibited different thermal distortions with the aluminum top sheet undergoing greater distortion than the bottom steel sheet due to a higher coefficient of thermal expansion.

Similar content being viewed by others

References

Thomy C, Vollertsen F (2012) Laser-MIG hybrid welding of aluminium to steel – effect of process parameters on joint properties. Weld World 56:124–132

Das A, Shome M, Goecke S-F, De A (2017) Joining of aluminium alloy and galvanized steel using a controlled gas metal arc process. J Manuf Process 27:179–187

Sierra G, Peyre P, Beaume FD, Stuart D, Fras G (2008) Steel to aluminium braze welding by laser process with Al-12Si filler wire. Sci Technol Weld Join 13:430–437

Zhang HT, Feng JC, He P (2008) Interfacial phenomena of cold metal transfer (CMT) welding of zinc coated steel and wrought aluminum. Mater Sci Technol 24:1346–1349

Su Y, Hua X, Wu Y (2014) Influence in alloy elements on microstructure and mechanical property of aluminum–steel lap joint made by gas metal arc welding. J Mater Process Technol 214:750–755

Cao R, Yu G, Chen JH, Wang PC (2013) Cold metal transfer joining of aluminum alloys-to-galvanized mild steel. J Mater Process Technol 213:1753–1763

Dong H, Hu W, Duan Y, Wang X, Dong C (2012) Dissimilar metal joining of aluminum alloy to galvanized steel with Al-Si, Al-Cu, Al-Si-Cu and Zn-Al filler wires. J Mater Process Technol 212:458–464

Yang S, Zhang J, Lian J, Lei Y (2013) Welding of aluminum alloy to zinc coated steel by cold metal transfer. Mater Design 49:602–612

Yagati KP, Bathe RN, Raajulapati KV, Rao KBS, Padmanabham G (2014) Fluxless arc weld-brazing of aluminium alloy to steel. J Mater Process Technol 214:2949–2959

Das A, Shome M, Goecke S-F, De A (2015) Joining of galvannealed steel and aluminium alloy using controlled short circuiting gas metal arc welding process. Sci Technol Weld Join 20(5):402–408

Deng D, Murukawa H (2008) Prediction of welding distortion and residual stress in a thin plate butt-welded joint. Comput Mater Sci 43:353–365

Goecke S-F, Syed AA, Spiegel ME, De A (2013) Probing current, voltage and metal transfer characteristics in pulsed arc and in conventional and a novel low energy input short arc GMAW. Quart J Jpn Weld Soc 31(4):26s–30s

Frostevarg J, Kaplan AFH, Lamas J (2014) Comparison of CMT with other arc modes for laser-arc hybrid welding of steel. Weld World 58:649–660

Schenk T, Richardson IM, Kraska M, Ohnimus S (2009) Modeling buckling distortion of DP600 overlap joints due to gas metal arc welding and the influence of the mesh density. Comput Mater Sci 46:977–986

BS EN 12797:2000 (2004) Brazing – destructive tests of brazed joints. British Standard, London

Pepe N, Egerland S, Colegrove PA, Yapp D, Leonhartsberger A, Scotti A (2011) Measuring the process efficiency of controlled gas metal arc welding processes. Sci Technol Weld Join 16(5):412–417

Makwana P, Shome M, Goecke S-F, De A (2016) Wetting length in gas metal arc brazing of galvanized steel. Sci Technol Weld Join 22(2):166–169

El-Batahgy A, Kutsuna M (2009) Laser beam welding of AA5052, AA5083 and AA6061 aluminium alloys. Adv Mater Sci Eng 9. https://doi.org/10.1155/2009/974182

Gale WF, Totemeier TC (2004) Smithells metals reference book, 8th edn. Elsevier, Oxford

Mills KC (2002) Recommended values of thermophysical properties for selected commercial alloys. Woodhead, Cambridge

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission XII - Arc Welding Processes and Production Systems

Rights and permissions

About this article

Cite this article

Goecke, SF., Makwana, P., Shome, M. et al. Probing joint strength and distortion in gas metal arc lap joining of aluminum and steel sheets. Weld World 63, 229–236 (2019). https://doi.org/10.1007/s40194-018-0653-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-018-0653-z