Abstract

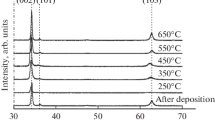

The mechanism for the deposition of zinc to form porous thin films is not clearly understood. In this study, a modified direct current (DC) sputtering system was used to deposit polycrystalline porous zinc thin films on an amorphous glass substrate to elucidate the mechanism. Subsequently, the properties of the thin films, such as its film thickness, the average particle size, and its porosity, were investigated under different experimental parameters, including pressure, DC discharge power, and the gas ratio between Ar and He. The plasma properties were also studied using a Langmuir probe. An increase in deposition pressure and DC discharge power was found to increase the deposition thickness and the particle size in the thin films whereas an increase in the He content increased the thickness and decreased the particle size. The investigation of the growth mechanism revealed that the zinc particles were oriented in different planes at early and later stages of deposition. Moreover, the properties of the thin films were observed to be affected by the energy loss of the zinc atoms and the bonding force between the substrate and the zinc particles. This understanding of the mechanism of thin-film formation will help to guide the optimization of experimental parameters in the fabrication of high-quality thin films.

Similar content being viewed by others

References

J. Liu, S.Z. Qiao, Q.H. Hu, G.Q. Lu, Small 7, 418 (2011). https://doi.org/10.1002/smll.201190008

P. Mohanpuria, N.K. Rana, S.K. Yadav, J. Nanopart. Res. 10, 507 (2008). https://doi.org/10.1007/s11051-007-9275-x

H. Wang, Y. Wang, X. Wang, Electrochem. commun. 18, 92 (2012). https://doi.org/10.1016/j.elecom.2012.02.023

H. Fei, Y. Yang, X. Fan, G. Wang, G. Ruan, J.M. Tour, J. Mater. Chem. A 3, 5798 (2015). https://doi.org/10.1039/c4ta06938b

Y. Yang, H. Fei, G. Ruan, J.M. Tour, Adv. Mater. 27, 3175 (2015). https://doi.org/10.1002/adma.201500894

Z. Dai, L. Xu, G. Duan, T. Li, H. Zhang, Y. Li, Y. Wang, Y. Wang, W. Cai, Sci. Rep. 3, 1 (2013). https://doi.org/10.1038/srep01669

P. Kumar, K.H. Kim, K. Vellingiri, P. Samaddar, P. Kumar, A. Deep, N. Kumar, Biosens. Bioelectron. 104, 120 (2018). https://doi.org/10.1016/j.bios.2018.01.006

Y. Xu, L. Zheng, C. Yang, W. Zheng, X. Liu, J. Zhang, A.C.S. Appl, Mater. Interfaces 12, 20704 (2020). https://doi.org/10.1021/acsami.0c04398

C.K. Hwang, J.M. Kim, S. Hwang, J.H. Kim, C.H. Sung, B.M. Moon, K.H. Chae, J.P. Singh, S.H. Kim, S.S. Jang et al., Adv. Mater. Interfaces 7, 1 (2020). https://doi.org/10.1002/admi.201901326

P. Liu, X. Ling, C. Zhong, Y. Deng, X. Han, W. Hu, Front. Chem. 7, 1 (2019). https://doi.org/10.3389/fchem.2019.00656

M.N. Masri, M.F.M. Nazeri, C.Y. Ng, A.A. Mohamad, J. King Saud Univ. Eng. Sci. 27, 217 (2015). https://doi.org/10.1016/j.jksues.2013.06.001

Z. Liu, T. Fan, D. Zhang, X. Gong, J. Xu, Sens. Actuators B Chem. 136, 499 (2009). https://doi.org/10.1016/j.snb.2008.10.043

M. Laurenti, V. Cauda, Coatings 8, 67 (2018). https://doi.org/10.3390/coatings8020067

Q. Simon, D. Barreca, A. Gasparotto, C. MacCato, T. Montini, V. Gombac, P. Fornasiero, O.I. Lebedev, S. Turner, G. van Tendeloo, J. Mater. Chem. 22, 11739 (2012). https://doi.org/10.1039/c2jm31589k

R. Chen, C. Zou, X. Yan, A. Alyamani, W. Gao, Thin Solid Films 519, 1837 (2011). https://doi.org/10.1016/j.tsf.2010.10.012

M.A. Borysiewicz, E. Dynowska, V. Kolkovsky, J. Dyczewski, M. Wielgus, E. Kamińska, A. Piotrowska, Phys. Status Solidi Appl. Mater. Sci. 209, 2463 (2012). https://doi.org/10.1002/pssa.201228041

Y.G. Wang, S.P. Lau, H.W. Lee, S.F. Yu, B.K. Tay, X.H. Zhang, H.H. Hng, J. Appl. Phys. 94, 354 (2003). https://doi.org/10.1063/1.1577819

M. Karyaoui, A.B. Jaballah, R. Mechiak, R. Chtourou, I.O.P. Conf, Ser. Mater. Sci. Eng. 28, 1 (2012). https://doi.org/10.1088/1757-899X/28/1/012019

Z. Liu, Z. Jin, W. Li, J. Qiu, Mater. Lett. 59, 3620 (2005). https://doi.org/10.1016/j.matlet.2005.06.064

Z. Chen, A. Xiao, Y. Chen, C. Zuo, S. Zhou, L. Li, J. Phys. Chem. Solids 74, 1522 (2013). https://doi.org/10.1016/j.jpcs.2013.05.015

L. Van Duy, N.H. Hanh, D.N. Son, P.T. Hung, C.M. Hung, N. van Duy, N.D. Hoa, N. van Hieu, F. Ke, J. Nanomater. 2019, 1 (2019). https://doi.org/10.1155/2019/4867909

E. Michaelis, D. Wöhrle, J. Rathousky, M. Wark, Thin Solid Films 497, 163 (2006). https://doi.org/10.1016/j.tsf.2005.10.072

D. Vick, T. Smy, M.J. Brett, J. Mater. Res. 17, 2904 (2002). https://doi.org/10.1557/JMR.2002.0421

H.M. Al Dosari, A.I. Ayesh, J. Appl. Phys. 114, 054305 (2013). https://doi.org/10.1063/1.4817421

O. Carton, J. Ghaymouni, M. Lejeune, A. Zeinert, J. Spectrosc. 2013, 1 (2013). https://doi.org/10.1155/2013/307824

J. Zeng, M. Hu, W. Wang, H. Chen, Y. Qin, Sens. Actuators B Chem. 161, 447 (2012). https://doi.org/10.1016/j.snb.2011.10.059

F. Oudrhiri-Hassani, L. Presmanes, A. Barnabé, P. Tailhades, Appl. Surf. Sci. 254, 5796 (2008). https://doi.org/10.1016/j.apsusc.2008.03.149

I. Sandu, L. Presmanes, P. Alphonse, P. Tailhades, Thin Solid Films 495, 130 (2006). https://doi.org/10.1016/j.tsf.2005.08.318

A. Borrás, A. Barranco, A.R. González-Elipe, J. Mater. Sci. 41, 5220 (2006). https://doi.org/10.1007/s10853-006-0431-y

Q. Zhou, Z. Li, J. Ni, Z. Zhang, Mater. Trans. 52, 469 (2011). https://doi.org/10.2320/matertrans.m2010342

Q. Zhou, Z. Li, Y. Yang, Z. Zhang, J. Phys. D 41, 152007 (2008). https://doi.org/10.1088/0022-3727/41/15/152007

R. Chen, C. Zou, X. Yan, W. Gao, Prog. Nat. Sci. Mater. Int. 21, 81 (2001). https://doi.org/10.1016/S1002-0071(12)60041-0

R. Gazia, A. Chiodoni, S. Bianco, A. Lamberti, M. Quaglio, A. Sacco, E. Tresso, P. Mandracci, C.F. Pirri, Thin Solid Films 524, 107 (2012). https://doi.org/10.1016/j.tsf.2012.09.076

B.Q. Fu, W. Liu, Z.L. Li, Appl. Surf. Sci. 255, 9348 (2009). https://doi.org/10.1016/j.apsusc.2009.07.034

Z.W. Li, W. Gao, Thin Solid Films 515, 3323 (2007). https://doi.org/10.1016/j.tsf.2006.09.026

A.K. Abduev, A.K. Akhmedov, A.S. Asvarov, N.M.-R. Alikhanov, R.M. Emirov, A.E. Muslimov, V.V. Belyaev, Crystallogr. Rep. 62, 133 (2017). https://doi.org/10.1134/s1063774517010023

Acknowledgements

This work was supported by a sabbatical year research grant from Korea Polytechnic University and by the Priority Research Center Program (NRF-2017 R1A6A1A03015562) funded by the Ministry of Education (MOE) of the Republic of Korea.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rho, S.H., Kim, H.G., Park, S.Y. et al. Study on the mechanism for the deposition of a porous zinc thin film by using a modified DC magnetron sputtering system. J. Korean Phys. Soc. 78, 679–687 (2021). https://doi.org/10.1007/s40042-021-00101-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40042-021-00101-6