Abstract

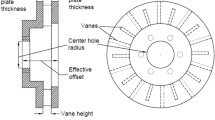

Brake discs are crucial part of any automobile, since they provide frictional effect for braking. They should be reliable and have long functional life. In this regard, both the fatigue life of the brake disc and its ability to resist axial deflection is important. In this research, a finite element model for a ventilated brake disc is developed to numerically simulate the fatigue life and axial deflection. The effective performance of the brake disc is analysed using a two-level full factorial design based on five different design parameters, namely inboard plate thickness, outboard plate thickness, vane height, effective offset and centre hole radius. To analyse and compare the various design parameter combinations, multi-criteria decision-making (MCDM) is used. A comprehensive comparative study for determination of design parameters is carried out by using four different MCDM methods. It is found that the optimal predictions of the four MCDMs used in the study have a high correlation. Furthermore, based on the research, a higher-level setting of all the five design variables is found to be most suitable. However, all the other four design variables except inboard plate thickness are found to have a low influence on the multi-criteria brake performance.

Similar content being viewed by others

References

A. Afzal, M.A. Mujeebu, Thermo-mechanical and structural performances of automobile disc brakes: a review of numerical and experimental studies. Arch. Comput. Methods Eng. 26, 1489–1513 (2019)

M. Duzgun, Investigation of thermo-structural behaviors of different ventilation applications on brake discs. J. Mech. Sci. Technol. 26, 235–240 (2012)

H.B. Yan, Q.C. Zhang, T.J. Lu, An X-type lattice cored ventilated brake disc with enhanced cooling performance. Int. J. Heat Mass Transf. 80, 458–468 (2015)

H.B. Yan, Q.C. Zhang, T.J. Lu, Heat transfer enhancement by X-type lattice in ventilated brake disc. Int. J. Therm. Sci. 107, 39–55 (2016)

A. Belhocine, O.I. Abdullah, Design and thermomechanical finite element analysis of frictional contact mechanism on automotive disc brake assembly. J. Fail. Anal. Prev. 20, 270–301 (2020)

G. Riva, G. Valota, G. Perricone, J. Wahlström, An FEA approach to simulate disc brake wear and airborne particle emissions. Tribol. Int. 138, 90–98 (2019)

M. Pevec, I. Potrc, G. Bombek, D. Vranesevic, Prediction of the cooling factors of a vehicle brake disc and its influence on the results of a thermal numerical simulation. Int. J. Autom. Technol. 13, 725–733 (2012)

M.M. Shahzamanian, B.B. Sahari, M. Bayat, F. Mustapha, Z.N. Ismarrubie, Finite element analysis of thermoelastic contact problem in functionally graded axisymmetric brake disks. Compos. Struct. 92, 1591–1602 (2010)

L. Zhang, D. Meng, Z. Yu, Theoretical Modeling and FEM Analysis of the Thermo-mechanical Dynamics of Ventilated Disc Brakes, SAE Technical Paper, Tech. rep. (2010)

S. Rajamanickam, J. Prasanna, Multi objective optimization during small hole electrical discharge machining (EDM) of Ti–6Al–4V using TOPSIS. Mater. Today Proc. 18, 3109–3115 (2019)

A.K. Srirangan, P. Sathiya, Optimisation of process parameters for gas tungsten arc welding of Incoloy 800HT using TOPSIS. Mater. Today Proc. 4, 2031–2039 (2017)

A. Memari, A. Dargi, M.R.A. Jokar, R. Ahmad, A.R.A. Rahim, Sustainable supplier selection: a multi-criteria intuitionistic fuzzy TOPSIS method. J. Manuf. Syst. 50, 9–24 (2019)

K. Vivekananda, G.N. Arka, S.K. Sahoo, Finite element analysis and process parameters optimization of ultrasonic vibration assisted turning (UVT). Procedia Mater. Sci. 6, 1906–1914 (2014)

M.K. Ghorabaee, M. Amiri, E.K. Zavadskas, J. Antucheviciene, A new hybrid fuzzy MCDM approach for evaluation of construction equipment with sustainability considerations. Arch. Civ. Mech. Eng. 18, 32–49 (2018)

P. Madhu, C.S. Dhanalakshmi, M. Mathew, Multi-criteria decision-making in the selection of a suitable biomass material for maximum bio-oil yield during pyrolysis. Fuel 277, 118109 (2020)

S. Boral, I. Howard, S.K. Chaturvedi, K. McKee, V.N.A. Naikan, A novel hybrid multi-criteria group decision making approach for failure mode and effect analysis: an essential requirement for sustainable manufacturing. Sustain. Prod. Consum. 21, 14–32 (2020)

I. Emovon, O.S. Oghenenyerovwho, Application of MCDM method in material selection for optimal design: a review. Results Mater. 7, 100115 (2020)

H.S. Dhiman, D. Deb, Fuzzy TOPSIS and fuzzy COPRAS based multi-criteria decision making for hybrid wind farms. Energy 202 (2020). https://doi.org/10.1016/j.energy.2020.117755

S.H. Mousavi-Nasab, A. Sotoudeh-Anvari, A comprehensive MCDM-based approach using TOPSIS, COPRAS and DEA as an auxiliary tool for material selection problems. Mater. Des. 121, 237–253 (2017)

A. Feizabadi et al., MCDM selection of pulse parameters for best tribological performance of Cr–Al2O3 nano-composite co-deposited from trivalent chromium bath. J. Alloys Compd. 727, 286–296 (2017)

Y. Bahrami, H. Hassani, A. Maghsoudi, BWM-ARAS: a new hybrid MCDM method for Cu prospectivity mapping in the Abhar area, NW Iran. Spat. Stat. 33, 100382 (2019)

M.K. Ghorabaee, E.K. Zavadskas, L. Olfat, Z. Turskis, Multi-criteria inventory classification using a new method of evaluation based on distance from average solution (EDAS). Informatica 26, 435–451 (2015)

E.K. Zavadskas, A. Kaklauskas, Pastatu sistemotechninis ivertinimas (Vilnius, Technika, 1996), p. 280

C.L. Hwang, K. Yoon, Multiple Decision Attribute Making: Methods and Applications (1981) Springer-Verlag, New York

E.K. Zavadskas, Z. Turskis, A new additive ratio assessment (ARAS) method in multicriteria decision-making. Technol. Econ. Dev. Econ. 16, 159–172 (2010)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Maheshwari, N., Choudhary, J., Rath, A. et al. Finite Element Analysis and Multi-criteria Decision-Making (MCDM)-Based Optimal Design Parameter Selection of Solid Ventilated Brake Disc. J. Inst. Eng. India Ser. C 102, 349–359 (2021). https://doi.org/10.1007/s40032-020-00650-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40032-020-00650-y