Abstract

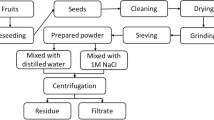

Wastewater effluents are great contributors to the ubiquitous problem of water contamination. Seen as one of the “greener” technology solutions, coagulation/flocculation technology utilises alternative coagulants of “green” origin. A life cycle assessment was performed in order to provide an environmental performance evaluation of three differently produced coagulants obtained from common bean seeds (Phaseolus vulgaris). The aim of the research was to compare production processes by identifying their hot spots and to determine which one was preferable from the ecological aspect. Furthermore, coagulation activity was determined and presented. The production processes included classic and ultrasound extraction, performed with 0.5 M NaCl solution as an extraction agent, and spray drying process conducted without or with carrier material (gum Arabic). Coagulant obtained by ultrasound extraction and dried with the help of carrier material, showed the lowest impact on the environment (around 50% lower than coagulants dried without carrier) while achieving high coagulation activity (61.5% of initial turbidity was reduced by the usage of 1 mL/L coagulant concentration). The life cycle assessment showed the highest impact from the production of all three types of coagulants originated from the electricity consumption mostly within spray drying phase (around 90% of total environmental impact originated from the mentioned phase). The coagulant production process has a relatively low environmental burden due to low chemical consumption, and it consisted of only a few simple production steps. Furthermore, possible improvements and optimisation of the production process hot spots were considered.

Similar content being viewed by others

References

Abeliotis K, Detsis V, Pappia C (2013) Life cycle assessment of bean production in the Prespa National Park Greece. J Clean Prod 41:89–96. https://doi.org/10.1016/j.jclepro.2012.09.032

Ali EN, Muyibi S, Salleh HM, Salleh MRM, Islamic I (2010) Production technique of natural coagulant from Moringa oleifera seeds. In: International water technology conference (IWTC 14), vol 14, Cairo, Egypt, pp 95–103

Ang WL, Mohammad AW (2020) State of the art and sustainability of natural coagulants in water and wastewater treatment. J Clean Prod 262:121267. https://doi.org/10.1016/j.jclepro.2020.121267

Directorate-General for Environment (2021) Annex I. Product environmental footprint method of the recommendation on the use of environmental footprint methods. https://ec.europa.eu/environment/publications/recommendation-use-environmental-footprint-methods_en. Accessed 10 May 2022

Antov MG, Šćiban MB, Petrović NJ (2010) Proteins from common bean (Phaseolus vulgaris) seed as a natural coagulant for potential application in water turbidity removal. Bioresour Technol 101:2167–2172. https://doi.org/10.1016/j.biortech.2009.11.020

Antov MG, Šćiban MB, Prodanović JM (2012) Evaluation of the efficiency of natural coagulant obtained by ultrafiltration of common bean seed extract in water turbidity removal. Ecol Eng 49:48–52. https://doi.org/10.1016/j.ecoleng.2012.08.015

Awad H, Gar Alalm M, El-Etriby HK (2019) Environmental and cost life cycle assessment of different alternatives for improvement of wastewater treatment plants in developing countries. Sci Total Environ 660:57–68. https://doi.org/10.1016/j.scitotenv.2018.12.386

Azapagic A, Millington A, Collett A (2006) A methodology for integrating sustainability considerations into process design. Chem Eng Res Des 84:439–452. https://doi.org/10.1205/cherd05007

Aziz AH, Alias S, Adlan MN, Faridah AAH, Zahari MS (2007) Colour removal from landfill leachate by coagulation and flocculation processes. Bioresour Technol 98:218–220. https://doi.org/10.1016/j.biortech.2005.11.013

Bajdur WM, Henclik A, Ščurek R, Sikorová K (2017) Ecological life cycle assessment of modified novolaks waste used in industrial wastewater treatment. Trans VSB Tech Univ Ostrava Saf Eng Ser 12:41–50. https://doi.org/10.1515/tvsbses-2017-0006

Barjoveanu G, Teodosiu C, Gilca A, Roman I, Fiore S (2019) Environmental performance evaluation of a drinking water treatment plant: a life cycle assessment perspective. Environ Eng Manag J 18:513–522. https://doi.org/10.30638/eemj.2019.048

Carlqvist K, Arshadi M, Mossing T, Östman U, Brännström H, Halmemies E, Nurmi J, Lidén G, Börjesson P (2020) Life-cycle assessment of the production of cationized tannins from Norway spruce bark as flocculants in wastewater treatment. Biofuel Bioprod Biorefin 16:1270–1285. https://doi.org/10.1002/bbb.2139

Chang Q, Zhang M, Wang J (2009) Removal of Cu2+ and turbidity from wastewater by mercaptoacetyl chitosan. J Hazard Mater 169:621–625. https://doi.org/10.1016/j.jhazmat.2009.03.144

Ciesielski K, Zbicinski I (2010) Evaluation of environmental impact of the spray-drying process. Dry Technol 28:37–41. https://doi.org/10.1080/07373937.2010.506164

CML (2016) https://www.universiteitleiden.nl/en/research/research-output/science/cml-ia-characterisation-factors. Accessed 28 Apr 2022

Colley TA, Birkved M, Olsen SI, Hauschild MZ (2020) Using a gate-to-gate LCA to apply circular economy principles to a food processing SME. J Clean Prod 251:119566. https://doi.org/10.1016/j.jclepro.2019.119566

Corominas L, Foley J, Guest JS, Hospido A, Larsen HF, Morera S, Shaw A (2013) Life cycle assessment applied to wastewater treatment: state of the art. Water Res 47:5480–5492. https://doi.org/10.1016/j.watres.2013.06.049

Corominas L, Byrne DM, Guest JS, Hospido A, Roux P, Shaw A, Short MD (2020) The application of life cycle assessment (LCA) to wastewater treatment: a best practice guide and critical review. Water Res 184:116058. https://doi.org/10.1016/j.watres.2020.116058

Flaten TP (2001) Aluminium as a risk factor in Alzheimer’s disease, with emphasis on drinking water. Brain Res Bull 55:187–196. https://doi.org/10.1016/s0361-9230(01)00459-2

Gallego-Schmid A, Tarpani RRZ (2019) Life cycle assessment of wastewater treatment in developing countries: a review. Water Res 153:63–79. https://doi.org/10.1016/j.watres.2019.01.010

Golbaz S, Jonidi A, Rafiee M, Rezaei R (2014) Separate and simultaneous removal of phenol, chromium, and cyanide from aqueous solution by coagulation/precipitation: mechanisms and theory. Chem Eng J 253:251–257. https://doi.org/10.1016/j.cej.2014.05.074

Goula AM, Adamopoulos KG (2010) A new technique for spray drying orange juice concentrate. Innov Food Sci Emerg Technol 11:342–351. https://doi.org/10.1016/j.ifset.2009.12.001

Guida S, Conzelmann L, Remy C, Vale P, Jefferson B, Soares A (2021) Resilience and life cycle assessment of ion exchange process for ammonium removal from municipal wastewater. Sci Total Environ 783:146834. https://doi.org/10.1016/j.scitotenv.2021.146834

Guinee J, Gorree M, Heijungs R (2002) Handbook on life cycle assessment. In: Guinee J (ed) Operational guide to the ISO standards. Kluwer, New York

Hjaila K, Baccar R, Sarrà M, Gasol CM, Blanquez P (2013) Environmental impact associated with activated carbon preparation from olive-waste cake via life cycle assessment. J Environ Manag 130:242–247. https://doi.org/10.1016/j.jenvman.2013.08.061

ISO 14040 (2006) Environmental management—life cycle assessment—principles and framework

ISO 14044 (2006) Environmental management—life cycle assessment—requirements and guidelines

Kokare S, Asif FMA, Mårtensson G, Shoaib-ul-Hasan S, Rashid A, Roci M, Salehi N (2022) A comparative life cycle assessment of stretchable and rigid electronics: a case study of cardiac monitoring devices. Int J Environ Sci Technol 19:3087–3102. https://doi.org/10.1007/s13762-021-03388-x

Krokida M, Taxiarchou M, Politis A, Peppas A, Kyriakopoulou K (2016) Life cycle assessment (LCA) on European skimmed milk powder processing production plant. Sci Bull Ser F Biotechnol 20:280–285

Lopes TAS, Queiroz LM, Torres EA, Kiperstok A (2020) Low complexity wastewater treatment process in developing countries: a LCA approach to evaluate environmental gains. Sci Total Environ 720:137593. https://doi.org/10.1016/j.scitotenv.2020.137593

Lopsik K (2013) Life cycle assessment of small-scale constructed wetland and extended aeration activated sludge wastewater treatment system. Int J Environ Sci Technol 10:1295–1308. https://doi.org/10.1007/s13762-012-0159-y

Pap S, Turk Sekulic M, Bremner B, Taggart MA (2021) From molecular to large-scale phosphorous recovery from wastewater using cost-effective adsorbents: an integrated approach. Integr Hybrid Process Technol Water Wastewater Treat. https://doi.org/10.1016/b978-0-12-823031-2.00025-2

Paulu A, Bartaček J, Šerešova M, Koči V (2021) Combining process modelling and LCA to assess the environmental impacts of wastewater treatment innovations. Water 13:1246. https://doi.org/10.3390/w13091246

Prosapio V, Norton I, De Marco I (2017) Optimization of freeze-drying using a life cycle assessment approach: strawberries’ case study. J Clean Prod 168:1171–1179. https://doi.org/10.1016/j.jclepro.2017.09.125

Rebello TA, Gonçalves RF, Calmon JL (2021) Mitigation of environmental impacts in warm-weather wastewater treatment plants using the life cycle assessment tool. Int J Environ Sci Technol. https://doi.org/10.1007/s13762-021-03430-y

Sabeen AH, Kamaruddin SNB, Noor ZZ (2019) Environmental impacts assessment of industrial wastewater treatment system using electroless nickel plating and life cycle assessment approaches. Int J Environ Sci Technol 16:3171–3182. https://doi.org/10.1007/s13762-018-1974-6

Saydi D, Hatamipour MS (2012) Analysis of the effective parameters on potato powder quality produced by a spray dryer. Iran J Chem Eng 9:55–62

Skipnes D, Van der Plancken I, Van Loey A, Hendrickx ME (2008) Kinetics of heat denaturation of proteins from farmed Atlantic cod (Gadus morhua). J Food Eng 85:51–58. https://doi.org/10.1016/j.jfoodeng.2007.06.030

Song P, Huang G, An C, Zhang P, Chen X, Ren S (2019) Performance analysis and life cycle greenhouse gas emission assessment of an integrated gravitational-flow wastewater treatment system for rural areas. Environ Sci Pollut Res 26:25883–25897. https://doi.org/10.1007/s11356-019-05746-2

Suarez S, Lema JM, Omil F (2009) Pre-treatment of hospital wastewater by coagulation–flocculation and flotation. Bioresour Technol 100:2138–2146. https://doi.org/10.1016/j.biortech.2008.11.015

Tontul I, Topuz A (2017) Spray-drying of fruit and vegetable juices: effect of drying conditions on the product yield and physical properties. Trends Food Sci Technol 63:91–102. https://doi.org/10.1016/j.tifs.2017.03.009

Trinh LTK, Hu AH, Lan YC, Chen ZH (2020) Comparative life cycle assessment for conventional and organic coffee cultivation in Vietnam. Int J Environ Sci Technol 17:1307–1324. https://doi.org/10.1007/s13762-019-02539-5

United Nations Development Programme (2019) https://www.undp.org/content/undp/en/home/sustainable-development-goals.html

Vidović SS, Vladić JZ, Vaštag G, Zeković ZP, Popović LM (2014) Maltodextrin as a carrier of health bene fi t compounds in Satureja montana dry powder extract obtained by spray drying technique. Powder Technol 258:209–215. https://doi.org/10.1016/j.powtec.2014.03.038

Vladić J, Ambrus R, Szabó-Révész P, Vasić A, Cvejin A, Pavlić B, Vidović S (2016) Recycling of filter tea industry by-products: production of A. millefolium powder using spray drying technique. Ind Crops Prod 80:197–206. https://doi.org/10.1016/j.indcrop.2015.11.085

Vukelic D, Boskovic N, Agarski B, Radonic J, Budak I, Pap S, Turk Sekulic M (2018) Eco-design of a low-cost adsorbent produced from waste cherry kernels. J Clean Prod 174:1620–1628. https://doi.org/10.1016/j.jclepro.2017.11.098

Wernet G, Bauer C, Steubing B, Reinhard J, Moreno-Ruiz E, Weidema B (2016) The ecoinvent database version 3 (part I): overview and methodology. Int J Life Cycle Assess 21:1218–1230. https://doi.org/10.1007/s11367-016-1087-8

Yin CY (2010) Emerging usage of plant-based coagulants for water and wastewater treatment. Process Biochem 45:1437–1444. https://doi.org/10.1016/j.procbio.2010.05.030

Acknowledgements

The research has been supported by the Ministry of Education, Science and Technological Development, Republic of Serbia, through the project number 451-03-68/2022-14/200156: “Innovative scientific and artistic research from the FTS (activity) domain” and by the Innovation Fund, Republic of Serbia, ID 5156 through the project Proof of Concept.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Editorial responsibility: Josef Trögl.

Appendices

Appendix 1: Life cycle inventory data

The life cycle inventory data for are listed in Table 2 for KNO, Table 3 for UNO, and in Table 4 for GA.

Appendix 2: Life cycle impact assessment and uncertainty analysis results

The life cycle impact assessment (LCIA) results are provided in Table 5 for KNO, Table 6 for UNO, and in Table 7 for GA. The LCIA results for grinding and screening phase are provided in Table 8, for extraction phase in Table 9, and for spray drying phase in Table 10. The LCIA uncertainty results for grinding and screening phase are provided in Table 11, for extraction phase in Table 12, and for spray drying phase in Table 13.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Radovic, S., Sekulic, M.T., Agarski, B. et al. Life cycle assessment of new bio-based coagulant production for sustainable wastewater treatment. Int. J. Environ. Sci. Technol. 20, 7433–7462 (2023). https://doi.org/10.1007/s13762-022-04440-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-022-04440-0