Abstract

Carbon-reinforced aluminum laminate (CARALL) structures, by exposure to various aging conditions, were studied to examine the effect of aging on their impact properties. After 40 thermal cycles between 25 and 100 ℃, there was improvement in impact strength of the structures with unidirectional configurations, with maximum improvement of 22.5%. Under isothermal condition (at constant temperature of 100 ℃), a 350 min aging caused 47.7% improvement in the impact strength. By applying cryogenic cycles between − 196 and 25 ℃, in some structures the impact strength improved after 20 cycles, whereas other structures improved after 50 cycles. The most improvement in the impact strength under cryogenic isothermal condition was about 53.5%, obtained after aging for 150 min at − 196 ℃. It was found that fibers pull out, fracturing, and layers delamination are the mechanisms responsible for deterioration of impact strength. Whereas, lateral and longitudinal crack propagation and the plastic deformation of aluminum layers are the energy absorption mechanisms, which can improve the impact strength.

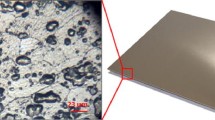

Graphical Abstract

Similar content being viewed by others

References

Ebrahimnezhad-Khaljiri H, Eslami-Farsani R (2017) Thermal and mechanical properties of hybrid carbon/oxidized polyacrylonitrile fibers-epoxy composites. Polym Compos 38:1412–1417. https://doi.org/10.1002/pc.23708

Turaka S, Reddy KVK, Sahu RK, Katiyar JK (2021) Mechanical properties of MWCNTs and graphene nanoparticles modified glass fibre-reinforced polymer nanocomposite. Bull Mater Sci 44:194. https://doi.org/10.1007/s12034-021-02444-z

Le Guen-Geffroy A, Davies P, Le Gac PY, Habert B (2020) Influence of seawater ageing on fracture of carbon fiber reinforced epoxy composites for ocean engineering. Oceans 1:198–214. https://doi.org/10.3390/oceans1040015

Najafi M, Darvizeh A, Ansari R (2018) Effect of nanoclay addition on the hygrothermal durability of glass/epoxy and fiber metal laminates. Fibers Polym 19:1956–1969. https://doi.org/10.1007/s12221-018-8235-7

Najafi M, Darvizeh A, Ansari R (2019) Effect of salt water conditioning on novel fiber metal laminates for marine applications. Proc Inst Mech Eng Part L J Mater Des Appl 233:1542–1554. https://doi.org/10.1177/1464420718767946

Li S, Chen D, Yuan Y, Gao C, Cui Y, Wang H, Liu X, Liu M, Wu Z (2020) Influence of flexible molecular structure on the cryogenic mechanical properties of epoxy matrix and carbon fiber/epoxy composite laminate. Mater Des 195:109028. https://doi.org/10.1016/j.matdes.2020.109028

Najafi M, Eslami-Farsani R, Saeedi A, Ebrahimnezhad-Khaljiri H (2022). In: Mavinkere Rangappa S, Parameswaranpillai J, Siengchin S, Thomas S (eds) Handbook of epoxy/fiber composites, 1st edn. Springer, Singapore. https://doi.org/10.1007/978-981-15-8141-0_16-1

Di Filippo M, Alessi S, Pitarresi G, Sabatino MA, Zucchelli A, Dispenza C (2016) Hydrothermal aging of carbon reinforced epoxy laminates with nanofibrous mats as toughening interlayers. Polym Degrad Stab 126:188–195. https://doi.org/10.1016/j.polymdegradstab.2016.02.011

Ebrahimnezhad-Khaljiri H (2022). In: Muthukumar C, Krishnasamy S, Thiagamani SMK, Siengchin S (eds) Aging effects on natural fiber-reinforced polymer composites, 1st edn. Springer, Singapore. https://doi.org/10.1007/978-981-16-8360-2_7

Bellenger V, Decelle J, Huet N (2005) Ageing of a carbon epoxy composite for aeronautic applications. Compos B 36:189–194. https://doi.org/10.1016/j.compositesb.2004.04.016

Zavatta N, Rondina F, Falaschetti MP, Donati L (2021) Effect of thermal ageing on the mechanical strength of carbon fibre reinforced epoxy composites. Polymers 13:2006. https://doi.org/10.3390/polym13122006

Sebaey TA (2020) Effect of exposure temperature on thecrashworthiness of carbon/epoxy compositerectangular tubes under quasi-static compression. Polymers 12:2028. https://doi.org/10.3390/POLYM12092028

Ammar-Khodja I, Picard C, Fois M, Marais C, Netchitaïlo P (2006) Preliminary results on thermo-oxidative ageing of multi-hole carbon/epoxy composites. Compos Sci Technol 69:1427–1431. https://doi.org/10.1016/j.compscitech.2008.09.014

Zhang M, Sun B, Gu B (2016) Accelerated thermal ageing of epoxy resin and 3-D carbon fiber/epoxy braided composites. Compos A 85:163–171. https://doi.org/10.1016/j.compositesa.2016.03.028

Tual N, Carrere N, Davies P, Bonnemains T, Lolive E (2015) Characterization of sea water ageing effects on mechanical properties of carbon/epoxy composites for tidal turbine blades. Compos A 78:380–389. https://doi.org/10.1016/j.compositesa.2015.08.035

He Y, Chen Q, Yang S, Lu C, Feng M, Jiang Y, Cao G, Zhang J, Liu C (2018) Micro-crack behavior of carbon fiber reinforced Fe3O4/graphene oxide modified epoxy composites for cryogenic application. Compos A 108:12–22. https://doi.org/10.1016/j.compositesa.2018.02.014

De S, Shivangi PN, Choudhury S, Fulmali AO, Ray BC, Prusty RK (2021) Effects of fiber surface grafting by functionalized carbon nanotubes on the interfacial durability during cryogenic testing and conditioning of CFRP composites. J Appl Polym Sci 138:51231. https://doi.org/10.1002/app.51231

Mirzamohammadi S, Eslami-Farsani R, Ebrahimnezhad-Khaljiri H (2022) The characterization of the flexural and shear performances of laminated aluminum/jute-basalt fibers epoxy composites containing carbon nanotubes: as multi-scale hybrid structures. Thin-Walled Struct 179:109690. https://doi.org/10.1016/j.tws.2022.109690

Jakubczak P, Bieniaś J, Droździel M (2020) The collation of impact behaviour of titanium/carbon, aluminum/carbon and conventional carbon fibres laminates. Thin-Walled Struct 155:106952. https://doi.org/10.1016/j.tws.2020.106952

Wu XT, Zhan LH, Huang MH, Zhao X, Wang X, Zhao GQ (2021) Corrosion damage evolution and mechanical properties of carbon fiber reinforced aluminum laminate. J Cent South Univ 28:657–668. https://doi.org/10.1007/s11771-021-4635-8

Lin Y, Huang Y, Huang T, Liao B, Zhang D, Li C (2019) Characterization of progressive damage behaviour and failure mechanisms of carbon fibre reinforced aluminium laminates under three-point bending. Thin-Walled Struct 135:494–506. https://doi.org/10.1016/j.tws.2018.12.002

Shamohammadi Maryan M, Ebrahimnezhad-Khaljiri H, Eslami-Farsani R (2022) The experimental assessment of the various surface modifications on the tensile and fatigue behaviors of laminated aluminum/aramid fibers-epoxy composites. Int J Fatigue 154:106560. https://doi.org/10.1016/j.ijfatigue.2021.106560

Ebrahimnezhad-Khaljiri H, Eslami-Farsani R, Talebi S (2020) Investigating the high velocity impact behavior of the laminated composites of aluminum/jute fibers-epoxy containing nanoclay particles. Fibers Polym 21:2607–2613. https://doi.org/10.1007/s12221-020-1209-6

García-Moreno I, Caminero MÁ, Rodríguez GP, López-Cela JJ (2019) Effect of thermal ageing on the impact and flexural damage behaviour of carbon fibre-reinforced epoxy laminates. Polymers 11:80. https://doi.org/10.3390/polym11010080

Najafi M, Ansari R (2019) Influence of thermal aging on mechanical properties of fiber metal laminates hybridized with nanoclay. Proc Inst Mech Eng Part C J Mech Eng Sci. 233:7003–7018. https://doi.org/10.1177/0954406219866871

Lafarie-Frenot MC (2006) Damage mechanisms induced by cyclic ply-stresses in carbon-epoxy laminates: environmental effects. Int J Fatigue 28:1202–1216. https://doi.org/10.1016/j.ijfatigue.2006.02.014

Daghia F, Zhang F, Cluzel C, Ladevèze P (2015) Thermo-mechano-oxidative behavior at the ply’s scale: The effect of oxidation on transverse cracking in carbon-epoxy composites. Compos Struct 134:602–612. https://doi.org/10.1016/j.compstruct.2015.08.103

Rahmani H, Eslami-Farsani R, Ebrahimnezhad-Khaljiri H (2020) High velocity impact response of aluminum-carbon fibers-epoxy laminated composites toughened by nano silica and zirconia. Fibers Polym 21:170–178. https://doi.org/10.1007/s12221-020-9594-4

Reis VL, Opelt CV, Cândido GM, Rezende MC, Donadon MV (2018) Effect of fiber orientation on the compressive response of plain weave carbon fiber/epoxy composites submitted to high strain rates. Compos Struct 203:952–959. https://doi.org/10.1016/j.compstruct.2018.06.016

Barjasteh E, Bosze EJ, Tsai YI, Nutt SR (2009) Thermal aging of fiberglass/carbon-fiber hybrid composites. Compos A 40:2038–2045. https://doi.org/10.1016/j.compositesa.2009.09.015

Shukla MJ, Kumar DS, Rathore DK, Prusty RK, Ray BC (2016) An assessment of flexural performance of liquid nitrogen conditioned glass/epoxy composites with multiwalled carbon nanotube. J Compos Mater 50:3077–3088. https://doi.org/10.1177/0021998315615648

Ray BC (2006) Adhesion of glass/epoxy composites influenced by thermal and cryogenic environments. J Appl Polym Sci 102:1943–1949. https://doi.org/10.1002/app.24488

Kim MG, Kang SG, Kim CG, Kong CW (2010) Tensile properties of carbon fiber composites with different resin compositions at cryogenic temperatures. Adv Compos Mater 19:63–77. https://doi.org/10.1163/156855109X434838

Najafi M, Ansari R, Darvizeh A (2019) Effect of cryogenic aging on nanophased fiber metal laminates and glass/epoxy composites. Polym Compos 40:2523–2533. https://doi.org/10.1002/pc.25134

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All the authors of this manuscript declare that there is no competing financial and conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Askari, M., Javadi, M., Eslami-Farsani, R. et al. Impact properties of carbon fibers-epoxy composite/aluminum laminates: effect of cryogenic and thermal aging. Iran Polym J 32, 187–201 (2023). https://doi.org/10.1007/s13726-022-01116-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-022-01116-x