Abstract

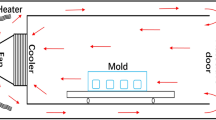

Composite materials have become increasingly more popular in aviation because of their good characteristics. One of the ways to fabricate composite products is through autoclave process. Due to the fact that in the molding process of the thermosets the performance and quality of composite products depend on mold temperature distributions, it would be necessary to analyze the heat transfer behavior on large size molds. A simulation was performed using finite element softwares to obtain temperature distributions on mold surfaces. The measured values were basically in good agreement with the simulated results. The simulation on the temperature stability was also studied and the simulated results of the temperature distribution, in the stabilized stage, were analyzed. The increases in temperature and simulation of the results of stabilization could provide guidance for the mold design. The novelty of the research is taking into account the influence of gravity and the real atmosphere considered as the environment of simulation. The K-epsilon turbulence model, which corresponds more exactly with the real conditions, was selected. Besides that, unstructured mesh was applied, because it accommodated well to complex geometrical shapes and generated suitable boundary layer.

Similar content being viewed by others

References

Yan D, Liu W, Huang G (2012) Design study for composites autoclave forming mould. Design Manuf Technol Die Mould 7:119–124

Yue G, Zhang J, Zhang B (2013) Study on the influence of mold on cure-induced deformation of composites structure. Acta Materiae Compositae Sinica 4:206–210

Gao Y, Qu CH (2012) Numerical simulation about heat-fluid coupling in autoclaves. Ind Furn 34:37–39

Zhang X, Gan Z, Zhang H (2011) Research on optimization of mold temperature fields in autoclave age forming. Manuf Inform Eng China 40:30–37

Yue G, Zhang B, Du S, Dai F (2010) Influence of the mould on curing induced shape distortion for resinmatrix thermosetting composites. Fiber Reinf Plast Compos 9:63–65

Zhang Ch (2009) Curing temperature field trade-off design method of large-scale composite material structure in autoclave process. Harbin Institute of Technology, Harbin

Gniatczyk JL, Aquilina GR, Deaver DT, Deavar DC (2000) Composite molding tools and processes of forming molding tools. US Patent 6309587 B1

Michael C, Niu Y (2005) Composite airframe structures. Conmilit Press Ltd, Hong Kong

Duval MF (2005) Investigation and modelling of the heat transfer process in carbon fibre/epoxy composite tools. PhD Thesis, Canada, Carleton University

Hudek M (2001) Examination of heat transfer during autoclave processing of polymer composites. MSc Thesis, Canada, University of Manitoba

Zhang J (2012) Research on composite molding process in autoclave based on FEA. Nanjing University of Aeronautics and Astronautics, Nanjing

Yue G, Zhang B, Du S, Dai F, Zhang CH, Liang X, Wang Y (2009) Geometrical deformations of the framed-mould in autoclave processing for composite structures. Acata Materiae Compositae Sinica 26:148–152

Yu G (2011) A technology of temperature field analysis in autoclave processing for airplane composite structures. Nanjing University of Aeronautics and Astronautics, Nanjing

Zhang CH, Zhang B, Wang Y (2010) Refined simulation on curing temperature field of composites structures. Dev Appl Mater 6:41–46

Zhan CH, Liang X, Wang Y (2011) Rules of impact of autoclave environment on frame mould temperature field of advanced composites. J Mater Sci Eng 29:547–553

Bai G, Yan D, Zhang D (2013) A study on the temperature field distribute property of large frame type molds. Acta Materiae Compositae Sinica 30:169–174

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, F., Zhan, L. & Xu, Y. Simulation of mold temperature distribution in a running process autoclave. Iran Polym J 24, 927–934 (2015). https://doi.org/10.1007/s13726-015-0384-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-015-0384-6