Abstract

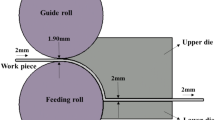

Fracture is one of the main criteria in designing industrial structures that its exact comprehension is highly significant in new sciences. This study analyzes the effect of equal channel angular rolling (ECAR) process on fracture mechanics in Al-7075 alloy ECARed through two routes of A and C and in Al-5052 alloy ECARed through the route of C. The results of analyzing fracture surfaces of samples, using scanning electron microscope, indicate that fracture has been ductile in samples without application of the process, on which a combination of shear and ductile fracture appeared after application. Moreover, it was observed that ECARed Al-7075 samples in route A have been fractured more in comparison with ECARed samples in route C. Also, the yield and tensile strengths increased and elongation decreased with increasing the number of passes in each pair of sheet.

Similar content being viewed by others

References

V.M. Segal, Equal channel angular extrusion: from macromechanics to structure formation. Mater. Sci. Eng. A 271(1), 322–333 (1999)

R. Jamaati, M.R. Toroghinejad, H. Edris, M.R. Salmani, Fabrication of nano/ultra-fine grained IF steel via SPD processes: a review. Trans. Indian Inst. Met. 67(6), 787–802 (2014)

M.E. Kassner, S.R. Barrabes, New developments in geometric dynamic recrystallization. Mater. Sci. Eng. A 410, 152–155 (2005)

A. Gholinia, F.J. Humphreys, P.B. Prangnell, Production of ultra-fine grain microstructures in Al–Mg alloys by coventional rolling. Acta Mater. 50(18), 4461–4476 (2002)

C. Borchers, C. Garve, M. Tiegel, M. Deutges, A. Herz, K. Edalati, R. Pippan, Z. Horita, R. Kirchheim, Nanocrystalline steel obtained by mechanical alloying of iron and graphite subsequently compacted by high-pressure torsion. Acta Mater. 97, 207–215 (2015)

M. Richert, H.J. McQueen, J. Richert, Micrbband formation in cyclic extrusion compression of aluminum. Can. Metall. Q. 37(5), 449–457 (1998)

M. Ebrahimi, F. Djavanroodi, C. Gode, K.M. Nikbin, Numerical prediction of the effects of material properties on strain behavior during equal channel angular pressing. Revue de Métallurgie-Int J Metall 110(5), 341–348 (2013)

A.O. Moghaddam, A. Mazinani, M. Ketabchi, Effect of accumulative roll bonding and equal channel angular rolling on microstructural and mechanical properties of Cu–Al–Mn shape memory alloys. Trans. Indian Inst. Met. 70(7), 1901–1909 (2017)

M. Javidikia, R. Hashemi, Analysis and simulation of parallel tubular channel angular pressing of Al 5083 tube. Trans. Indian Inst. Met. 70(10), 2547–2553 (2017)

M. Ebrahimi, S.N. Tiji, F. Djavanroodi, Upper bound solution of equal channel forward extrusion process as a new severe plastic deformation method. Metall. Res. Technol. 112(6), 609 (2015)

F. Nazari, M. Honarpisheh, Effect of stress relief annealing on microstructure, mechanical properties, and residual stress of a copper sheet in the constrained groove pressing process. Int. J. Adv. Manuf. Technol. (2019). https://doi.org/10.1007/s00170-019-03511-w

F. Nazari, M. Honarpisheh, Analytical model to estimate force of constrained groove pressing process. J. Manuf. Process. 32, 11–19 (2018)

F. Nazari , M. Honarpisheh, Analytical and experimental investigation of deformation in constrained groove pressing process, in Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science (2018): 0954406218809738

K. Nakashima, Z. Horita, M. Nemoto, T.G. Langdon, Development of a multi-pass facility for equal-channel angular pressing to high total strains. Mater. Sci. Eng. A 281(1), 82–87 (2000)

C.Y. Nam, J.H. Han, Y.H. Chung, M.C. Shin, Effect of precipitates on microstructural evolution of 7050 Al alloy sheet during equal channel angular rolling. Mater. Sci. Eng. A 347(1), 253–257 (2003)

J.-W. Park, J.-W. Kim, Y.-H. Chung, Grain refinement of steel plate by continuous equal-channel angular process. Scr. Mater. 51(2), 181–184 (2004)

Y.H. Chung, J. Woo Park, K.H. Lee, An analysis of accumulated deformation in the equal channel angular rolling (ECAR) process. Met. Mater. Int. 12(4), 289–292 (2006)

Y.Q. Cheng, Z.H. Chen, W.J. Xia, Drawability of AZ31 magnesium alloy sheet produced by equal channel angular rolling at room temperature. Mater. Charact. 58(7), 617–622 (2007)

F.Z. Hassani, M. Ketabchi, Nano grained AZ31 alloy achieved by equal channel angular rolling process. Mater. Sci. Eng. A 528(21), 6426–6431 (2011)

A. Habibi, M. Ketabchi, M. Eskandarzadeh, Nano-grained pure copper with high-strength and high-conductivity produced by equal channel angular rolling process. J. Mater. Process. Technol. 211(6), 1085–1090 (2011)

T. Kvačkaj, A. Kováčová, M. Kvačkaj, R. Kočiško, L. Lityńska-Dobrzyńska, V. Stoyka, M. Miháliková, TEM studies of structure in OFHC copper processed by equal channel angular Rolling. Micron 43(6), 720–724 (2012)

A. Habibi, M. Ketabchi, Enhanced properties of nano-grained pure copper by equal channel angular rolling and post-annealing. Mater. Des. 34, 483–487 (2012)

M. Mahmoodi, M. Sedighi, D.A. Tanner, Investigation of through thickness residual stress distribution in equal channel angular rolled Al 5083 alloy by layer removal technique and X-ray diffraction. Mater. Des. 40, 516–520 (2012)

M. Honarpisheh, M. Dehghani, E. Haghighat, Investigation of mechanical properties of Al/Cu strip produced by equal channel angular rolling. Proc. Mater. Sci. 11, 1–5 (2015)

M. Honarpisheh, M.R. Aghili, M. Kotobi, Experimental investigation of thermal conductivity of aluminum alloy 3003 produced by equal channel angular rolling process. J. Mod. Process. Manuf. Prod. 4(4), 29–38 (2015)

ASTM E8/E8M–09. Standard Test Methods for Tension Testing of Metallic Materials (ASTM International, Pennsylvania, 2009)

A. Azimi, S. Tutunchilar, G. Faraji, M.B. Givi, Mechanical properties and microstructural evolution during multi-pass ECAR of Al 1100–O alloy. Mater. Des. 42, 388–394 (2012)

S.S. Entezami, M. Honarpisheh, A study on the hardness of 7075 and 5052 aluminum alloys in the equal channel angular rolling process. Bulletin de la Société Royale des Sciences de Liège 85, 879–889 (2016)

N.Q. Chinh, J. Gubicza, T. Czeppe, J. Lendvai, X. Cheng, R.Z. Valiev, T.G. Langdon, Developing a strategy for the processing of age-hardenable alloys by ECAP at room temperature. Mater. Sci. Eng. A 516(1–2), 248–252 (2009)

Y.H. Zhao, X.Z. Liao, Z. Jin, R.Z. Valiev, Y.T. Zhu, Microstructures and mechanical properties of ultrafine grained 7075 Al alloy processed by ECAP and their evolutions during annealing. Acta Mater. 52(15), 4589–4599 (2004)

N. Tsuji, Y. Ito, Y. Saito, Y. Minamino, Strength and ductility of ultrafine grained aluminum and iron produced by ARB and annealing. Scr. Mater. 47(12), 893–899 (2002)

M. Honarpisheh, E. Haghighat, M. Kotobi, Investigation of residual stress and mechanical properties of equal channel angular rolled St12 strips. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 232(10), 841–851 (2018)

M. Asemabadi, M. Sedighi, M. Honarpisheh, Investigation of cold rolling influence on the mechanical properties of explosive-welded Al/Cu bimetal. Mater. Sci. Eng. A 558, 144–149 (2012)

M. Kotobi, M. Honarpisheh, Uncertainty analysis of residual stresses measured by slitting method in equal-channel angular rolled Al-1060 strips. J. Strain Anal. Eng. Des. 52(2), 83–92 (2017)

B.L. Gabriel, Scanning electron microscopy. ASM Handb. 12, 173–175 (1998)

M.R. Toroghinejad, F. Ashrafizadeh, R. Jamaati, On the use of accumulative roll bonding process to develop nanostructured aluminum alloy 5083. Mater. Sci. Eng. A 561, 145–151 (2013)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Honarpisheh, M., Entezami, S.S. & Akhavan, S. Effect of Equal Channel Angular Rolling Process on the Fracture Mechanisms of Al-7057 and Al-5052 Alloys. Metallogr. Microstruct. Anal. 8, 336–348 (2019). https://doi.org/10.1007/s13632-019-00540-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-019-00540-5