Abstract

Diatom biomass could be an alternative feedstock for producing bio-oil through hydrothermal liquefaction (HTL) technique. Additionally, diatom biomass could have high-value metabolites, such as pigments and polyunsaturated fatty acids. Hence, this study investigated the feasibility of using indigenous marine diatom biomass as a potential feedstock for biocrude oil and high-value products. At first, different growth parameters (i.e., nutrient type and concentration, and salinity) were studied for locally isolated Amphora sp. and Nitzschia sp. diatoms in indoor experiments. For all the parameters, Nitzschia sp. showed better growth rate and biomass yield compared to Amphora sp. Therefore, Nitzschia sp. was selected as the candidate strain, and it was grown outside in a 1000-L raceway tank. The final biomass yield was 0.57 g/L, and the biomass was first concentrated using a tangential flow filtration membrane followed by a centrifuge. The harvested biomass’s lipid, protein, carbohydrate, and ash contents were 22.2, 15.5, 34.4, and 27.8%, respectively. The docosahexaenoic acid and eicosatetraenoic acid contents were 13.0 and 10.9% of lipid, respectively. The carotenoid content in the biomass was 12 mg/g biomass. Next, hydrothermal liquefaction (HTL) treatment was applied to Nitzschia biomass at a temperature range of 300–400 °C. Biocrude yield and their higher heating values (HHV) ranged from 36.5 to 57.2% and from 24.7 to 35.1 MJ/kg, respectively; while the maximum biocrude yield was obtained at 375 °C, the highest HHV was obtained at 300 °C. The aromatics and the heterofunctional compounds were the major compounds for all the biocrude samples. The energy recovery (i.e., 64.3%) and energy return on investment (i.e., 1.68) for the biocrude samples were higher at 375 °C, mainly due to the higher biocrude yield at this temperature. Overall, Nitzschia sp. is a potential candidate strain for bio-oil production in a biorefinery route.

Similar content being viewed by others

References

Panahi H, Kazemi S, Tabatabaei M, Aghbashlo M et al (2019) Recent updates on the production and upgrading of bio-crude oil from microalgae. Bioresour Technol Reports 7:100216. https://doi.org/10.1016/j.biteb.2019.100216

Shuba ES, Kifle D (2018) Microalgae to biofuels: ‘promising’ alternative and renewable energy, review. Renew Sustain Energy Rev 81:743–755. https://doi.org/10.1016/j.rser.2017.08.042

Hermiyanty WA, Bertin DS (2017) Proposal for a regulation of the European Parliament and of the council establishing the framework for achieving climate neutrality and amending Regulation (EU) 2018/1999 (European Climate Law) EN. J Chem Inf Model. https://doi.org/10.1017/CBO9781107415324.004

Athanasakoglou A, Grypioti E, Michailidou S et al (2019) Isoprenoid biosynthesis in the diatom Haslea ostrearia. New Phytol 222:230–243. https://doi.org/10.1111/nph.15586

Levitan O, Dinamarca J, Hochman G, Falkowski PG (2014) Diatoms: a fossil fuel of the future. Trends Biotechnol 32:117–124. https://doi.org/10.1016/j.tibtech.2014.01.004

Vella FM, Sardo A, Gallo C et al (2019) Annual outdoor cultivation of the diatom Thalassiosira weissflogii: productivity, limits and perspectives. Algal Res. https://doi.org/10.1016/j.algal.2019.101553

Graham JM, Graham LE, Zulkifly SB et al (2012) Freshwater diatoms as a source of lipids for biofuels. J Ind Microbiol Biotechnol. https://doi.org/10.1007/s10295-011-1041-5

Marella TK, Parine NR, Tiwari A (2018) Potential of diatom consortium developed by nutrient enrichment for biodiesel production and simultaneous nutrient removal from waste water. Saudi J Biol Sci 25:704–709. https://doi.org/10.1016/j.sjbs.2017.05.011

Rahul SM, Sundaramahalingam MA, Shivamthi CS et al (2021) Insights about sustainable biodiesel production from microalgae biomass: a review. Int J Energy Res. https://doi.org/10.1002/er.6138

Muhammad G, Alam MA, Mofijur M, et al (2021) Modern developmental aspects in the field of economical harvesting and biodiesel production from microalgae biomass. Renew Sustain Energy Rev 135:110209. https://doi.org/10.1016/j.rser.2020.110209

Frank ED, Elgowainy A, Han J, Wang Z (2013) Life cycle comparison of hydrothermal liquefaction and lipid extraction pathways to renewable diesel from algae. Mitig Adapt Strateg Glob Chang. https://doi.org/10.1007/s11027-012-9395-1

Eboibi BE, Lewis DM, Ashman PJ, Chinnasamy S (2014) Effect of operating conditions on yield and quality of biocrude during hydrothermal liquefaction of halophytic microalga Tetraselmis sp. Bioresour Technol. https://doi.org/10.1016/j.biortech.2014.07.083

Mishra S, Mohanty K (2020) Co-HTL of domestic sewage sludge and wastewater treatment derived microalgal biomass – an integrated biorefinery approach for sustainable biocrude production. Energy Convers Manag 204:112312. https://doi.org/10.1016/j.enconman.2019.112312

Vardon DR, Sharma BK, Scott J et al (2011) Chemical properties of biocrude oil from the hydrothermal liquefaction of Spirulina algae, swine manure, and digested anaerobic sludge. Bioresour Technol. https://doi.org/10.1016/j.biortech.2011.06.041

López Barreiro D, Martin-Martinez FJ, Torri C et al (2018) Molecular characterization and atomistic model of biocrude oils from hydrothermal liquefaction of microalgae. Algal Res. https://doi.org/10.1016/j.algal.2018.08.034

He S, Zhao M, Wang J et al (2020) Hydrothermal liquefaction of low-lipid algae Nannochloropsis sp. and Sargassum sp.: effect of feedstock composition and temperature. Sci Total Environ. https://doi.org/10.1016/j.scitotenv.2019.135677

Palomino A, Godoy-Silva RD, Raikova S, Chuck CJ (2020) The storage stability of biocrude obtained by the hydrothermal liquefaction of microalgae. Renew Energy. https://doi.org/10.1016/j.renene.2019.07.084

Biller P, Ross AB (2011) Potential yields and properties of oil from the hydrothermal liquefaction of microalgae with different biochemical content. Bioresour Technol 102:215–225. https://doi.org/10.1016/j.biortech.2010.06.028

Ambati RR, Gogisetty D, Aswathanarayana RG, et al (2019) Industrial potential of carotenoid pigments from microalgae: current trends and future prospects. Crit Rev Food Sci Nutr 1880–1902. https://doi.org/10.1080/10408398.2018.1432561

Petrushkina M, Gusev E, Sorokin B et al (2017) Fucoxanthin production by heterokont microalgae. Algal Res. https://doi.org/10.1016/j.algal.2017.03.016

Mao X, Chen SHY, Lu X et al (2020) High silicate concentration facilitates fucoxanthin and eicosapentaenoic acid (EPA) production under heterotrophic condition in the marine diatom Nitzschia laevis. Algal Res. https://doi.org/10.1016/j.algal.2020.102086

Ishika T, Moheimani NR, Bahri PA et al (2017) Halo-adapted microalgae for fucoxanthin production: effect of incremental increase in salinity. Algal Res. https://doi.org/10.1016/j.algal.2017.10.002

Sun P, Wong CC, Li Y et al (2019) A novel strategy for isolation and purification of fucoxanthinol and fucoxanthin from the diatom Nitzschia laevis. Food Chem. https://doi.org/10.1016/j.foodchem.2018.10.133

Archer L, Mc Gee D, Paskuliakova A et al (2019) Fatty acid profiling of new Irish microalgal isolates producing the high-value metabolites EPA and DHA. Algal Res. https://doi.org/10.1016/j.algal.2019.101671

Chew KW, Yap JY, Show PL et al (2017) Microalgae biorefinery: high value products perspectives. Bioresour Technol. https://doi.org/10.1016/j.biortech.2017.01.006

Katiyar R, Arora A (2020) Health promoting functional lipids from microalgae pool: a review. Algal Res.

Das P, Thaher MI, Hakim MAQMA et al (2016) A comparative study of the growth of Tetraselmis sp. in large scale fixed depth and decreasing depth raceway ponds. Bioresour Technol 216:114–120. https://doi.org/10.1016/j.biortech.2016.05.058

Das P, Khan S, Thaher M et al (2019) Effect of harvesting methods on the energy requirement of Tetraselmis sp. biomass production and biocrude yield and quality. Bioresour Technol 284:9–15. https://doi.org/10.1016/j.biortech.2019.03.118

Das P, Thaher MI, Khan S et al (2019) Comparison of biocrude oil production from self-settling and non-settling microalgae biomass produced in the Qatari desert environment. Int J Environ Sci Technol. https://doi.org/10.1007/s13762-019-02364-w

Das P, Thaher M, Khan S, et al. (2019) The effect of culture salinity on the harvesting of microalgae biomass using pilot-scale tangential-flow-filter membrane. Bioresour Technol 122057. https://doi.org/10.1016/j.biortech.2019.122057

Kunene PN, Mahlambi PN (2020) Optimization and application of ultrasonic extraction and Soxhlet extraction followed by solid phase extraction for the determination of triazine pesticides in soil and sediment. J Environ Chem Eng. https://doi.org/10.1016/j.jece.2020.103665

Lichtenthaler HK, Wellburn AR (1983) Determinations of total carotenoids and chlorophylls a and b of leaf extracts in different solvents. Biochem Soc Trans 11:591–592. https://doi.org/10.1042/bst0110591

Das P, Khan S, AbdulQuadir M et al (2020) Energy recovery and nutrients recycling from municipal sewage sludge. Sci Total Environ 715:136775. https://doi.org/10.1016/j.scitotenv.2020.136775

Faiza Y, Al-Yamani F, Saburova M (2011) Illustrated guide on the benthic diatoms of Kuwait’s marine environment.

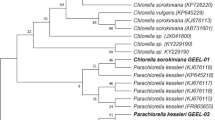

Barkia I, Zadjali F, Saari N et al (2018) Isolation and identification of indigenous marine diatoms (Bacillariophyta) for biomass production in open raceway ponds. Aquac Res. https://doi.org/10.1111/are.13539

Matsumoto M, Nojima D, Nonoyama T, et al. (2017) Outdoor cultivation of marine diatoms for year-round production of biofuels. Mar Drugs 15. https://doi.org/10.3390/md15040094

Bauer SK, Reynolds CF, Peng S, Colosi LM (2018) Evaluating the water quality impacts of hydrothermal liquefaction assessment of carbon, nitrogen, and energy recovery. Bioresour Technol Reports. https://doi.org/10.1016/j.biteb.2018.04.010

Yoo G, Park MS, Yang JW, Choi M (2015) Lipid content in microalgae determines the quality of biocrude and energy return on investment of hydrothermal liquefaction. Appl Energy. https://doi.org/10.1016/j.apenergy.2015.07.020

Yang J-H, Shin H-Y, Ryu Y-J, Lee C-G (2018) Hydrothermal liquefaction of Chlorella vulgaris: effect of reaction temperature and time on energy recovery and nutrient recovery. J Ind Eng Chem 68:267–273. https://doi.org/10.1016/j.jiec.2018.07.053

Makut BB, Goswami G, Das D (2020) Evaluation of bio-crude oil through hydrothermal liquefaction of microalgae-bacteria consortium grown in open pond using wastewater. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-020-00795-x

Sajjadi B, Chen WY, Raman AAA, Ibrahim S (2018) Microalgae lipid and biomass for biofuel production: a comprehensive review on lipid enhancement strategies and their effects on fatty acid composition. Renew Sustain Energy Rev 97:200–232. https://doi.org/10.1016/j.rser.2018.07.050

Klin M, Pniewski F, Latała A (2020) Growth phase-dependent biochemical composition of green microalgae: theoretical considerations for biogas production. Bioresour Technol. https://doi.org/10.1016/j.biortech.2020.122875

Maity JP, Bundschuh J, Chen CY, Bhattacharya P (2014) Microalgae for third generation biofuel production, mitigation of greenhouse gas emissions and wastewater treatment: present and future perspectives - a mini review. Energy. https://doi.org/10.1016/j.energy.2014.04.003

(2004) Photosynthesis in algae. J Phycol. https://doi.org/10.1111/j.1529-8817.2004.40601.x

Conde E, Balboa E, Parada M, et al. (2013) Algal proteins, peptides and amino acids. In: Functional ingredients from algae for foods and nutraceuticals 135–180

Uriarte I, Roberts R, Farías A (2006) The effect of nitrate supplementation on the biochemical composition of benthic diatoms and the growth and survival of post-larval abalone. Aquaculture. https://doi.org/10.1016/j.aquaculture.2006.08.007

Niccolai A, Chini Zittelli G, Rodolfi L et al (2019) Microalgae of interest as food source: biochemical composition and digestibility. Algal Res. https://doi.org/10.1016/j.algal.2019.101617

Chen YC (2012) The biomass and total lipid content and composition of twelve species of marine diatoms cultured under various environments. Food Chem. https://doi.org/10.1016/j.foodchem.2011.08.062

Cointet E, Wielgosz-Collin G, Méléder V, Gonçalves O (2019) Lipids in benthic diatoms: a new suitable screening procedure. Algal Res. https://doi.org/10.1016/j.algal.2019.101425

Duong VT, Thomas-Hall SR, Schenk PM (2015) Growth and lipid accumulation of microalgae from fluctuating brackish and sea water locations in South East Queensland—Australia. Front Plant Sci. https://doi.org/10.3389/fpls.2015.00359

Han Y, Hoekman SK, Cui Z et al (2019) Hydrothermal liquefaction of marine microalgae biomass using co-solvents. Algal Res 38:101421. https://doi.org/10.1016/j.algal.2019.101421

Hu Y, Gong M, Feng S, et al. (2019) A review of recent developments of pre-treatment technologies and hydrothermal liquefaction of microalgae for bio-crude oil production. Renew. Sustain. Energy Rev.

Kersten SRA, Knežević D, Venderbosch RH (2011) 18 - Production of biofuels via hydrothermal conversion BT - Handbook of Biofuels Production. In: Woodhead Publishing Series in Energy

Biller P, Ross AB, Skill SC et al (2012) Nutrient recycling of aqueous phase for microalgae cultivation from the hydrothermal liquefaction process. Algal Res 1:70–76. https://doi.org/10.1016/j.algal.2012.02.002

Garcia Alba L, Torri C, Samorì C, et al (2012) Hydrothermal treatment (HTT) of microalgae: evaluation of the process as conversion method in an algae biorefinery concept. Energy and Fuels 26(1):642–657. https://doi.org/10.1021/ef201415s

Guo B, Walter V, Hornung U, Dahmen N (2019) Hydrothermal liquefaction of Chlorella vulgaris and Nannochloropsis gaditana in a continuous stirred tank reactor and hydrotreating of biocrude by nickel catalysts. Fuel Process Technol. https://doi.org/10.1016/j.fuproc.2019.04.003

Li Z, Savage PE (2013) Feedstocks for fuels and chemicals from algae: Treatment of crude bio-oil over HZSM-5. Algal Res. https://doi.org/10.1016/j.algal.2013.01.003

Biller P, Ross AB (2012) Hydrothermal processing of algal biomass for the production of biofuels and chemicals. Biofuels 3:603–623. https://doi.org/10.4155/bfs.12.42

Eboibi BE, Lewis DM, Ashman PJ, Chinnasamy S (2014) Effect of operating conditions on yield and quality of biocrude during hydrothermal liquefaction of halophytic microalga Tetraselmis sp. Bioresour Technol 170:20–29. https://doi.org/10.1016/j.biortech.2014.07.083

Ren R, Han X, Zhang H et al (2018) High yield bio-oil production by hydrothermal liquefaction of a hydrocarbon-rich microalgae and biocrude upgrading. Carbon Resour Convers 1:153–159. https://doi.org/10.1016/j.crcon.2018.07.008

Obeid F, Van TC, Horchler EJ et al (2020) Engine performance and emissions of high nitrogen-containing fuels. Fuel. https://doi.org/10.1016/j.fuel.2019.116805

Hable RD, Alimoradi S, Sturm BSM, Stagg-Williams SM (2019) Simultaneous solid and biocrude product transformations from the hydrothermal treatment of high pH-induced flocculated algae at varying Ca concentrations. Algal Res. https://doi.org/10.1016/j.algal.2019.101501

Biller P, Ross AB (2016) Production of biofuels via hydrothermal conversion. In: Handbook of biofuels production: processes and technologies: Second Edition 509–547

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Al-Naimi, S., Al-Muftah, A., Das, P. et al. Biocrude oil and high-value metabolite production potential of the Nitzschia sp.. Biomass Conv. Bioref. 14, 7277–7290 (2024). https://doi.org/10.1007/s13399-021-02041-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-02041-4