Abstract

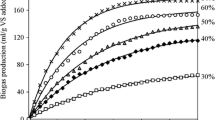

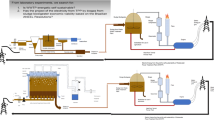

This study evaluated energy recovery from an upflow anaerobic sludge blanket (UASB) reactor treating paper industry wastewater and the goodness of fit of the Mantis2 model (i.e., using version 6.5 of the GPS-X™ software platform) to biogas and the effluent total chemical oxygen demand (COD) data. The UASB reactor achieved stable performance, exhibiting high COD removal efficiency about 96% for COD/SO42− = 5.0 on average. Experimental findings also revealed up to approximately 300 L/kg-CODrem. biogas yield indicating no clear inhibition due to high sulfate content. Daily biomethane production corresponded to approximately 25 kWh total energy (electricity+heat) generation per 1 m3 of wastewater treated. The overall goodness of fit of the model was satisfactory, based on the relatively low absolute deviations of 6.0% and 12.7% from the measured data for effluent COD and biogas generation, respectively. Besides, the resulting effluent COD simulation yielded a coefficient of determination (R2) value of 0.7663 and a mean absolute error (MAE) of about 39 mg/L. In light of experimental and simulation findings, the lab-scale UASB reactor indicated satisfactory performance and substantial biogas generation which would further encourage full-scale implementations of these promising energy recovery technologies in paper industries.

Similar content being viewed by others

References

ICI (2018) Istanbul Chamber of Industry. Paper and paper products manufacturing: Istanbul chamber of industry profession committees’ sectors strategies project in global competition. Istanbul (in Turkish)

Ashrafi O, Yerushalmi L, Haghighat F (2015) Wastewater treatment in the pulp-and-paper industry: a review of treatment processes and the associated greenhouse gas emission. J Environ Manag 158:146–157. https://doi.org/10.1016/j.jenvman.2015.05.010

Haq I, Mazumder P, Kalamdhad AS (2020) Recent advances in removal of lignin from paper industry wastewater and its industrial applications—a review. Bioresour Technol 312:123636. https://doi.org/10.1016/j.biortech.2020.123636

Thakur IS (2004) Pulp and paper mill effluent. In: Pandey A (ed) Concise encyclopedia of bioresource technology. Food Products Press, New York, pp 143–151

Wyman V, Henríquez J, Palma C, Carvajal A (2018) Lignocellulosic waste valorisation strategy through enzyme and biogas production. Bioresour Technol 247:402–411. https://doi.org/10.1016/j.biortech.2017.09.055

Sachan P, Madan S, Hussain A (2019) Isolation and screening of phenol-degrading bacteria from pulp and paper mill effluent. Appl Water Sci 9:1–6. https://doi.org/10.1007/s13201-019-0994-9

Thompson G, Swain J, Kay M, Forster CF (2001) The treatment of pulp and paper mill effluent: a review. Bioresour Technol 77:275–286. https://doi.org/10.1016/S0960-8524(00)00060-2

Nassar MM (2003) Studies on internal and external water treatment at a paper and cardboard factory. J Chem Technol Biotechnol 78:572–576. https://doi.org/10.1002/jctb.812

Isroi MR, Syamsiah S, Niklasson C, Cahyanto MN, Ludquist K, Taherzadeh MJ (2011) Biological pretreatment of lignocelluloses with white-rot fungi and its applications: a review. BioResources 6:5224–5259

Varjani S, Rakholiya P, Shindhal T, Shah AV, Ngo HH (2021) Trends in dye industry effluent treatment and recovery of value added products. J Water Process Eng 39:101734. https://doi.org/10.1016/j.jwpe.2020.101734

Kennedy JF, Panesar PS, Grover R, Marwaha SS (2006) Continuous methanogenesis of black liquor of pulp and paper mills in an anaerobic baffled reactor using an immobilized cell system. J Chem Technol Biotechnol 81:1277–1281. https://doi.org/10.1002/jctb.1546

Hamza RA, Iorhemen OT, Tay JH (2016) Advances in biological systems for the treatment of high-strength wastewater. J Water Process Eng 10:128–142. https://doi.org/10.1016/j.jwpe.2016.02.008

Bajpaj P (2017) Anaerobic technology in pulp and paper industry. In: applied sciences and technology.Spring nature, Singapore

Puyol D, Batstone DJ, Hulsen T, Astals S, Peces M, Kromer JO (2017) Resource recovery from wastewater by biological technologies: opportunities, challenges, and prospects. Front Microbiol 7:1–23. https://doi.org/10.3389/fmicb.2016.02106

Xu N, Liu S, Xin F, Zhou J, Jia H, Xu J, Jiang M, Dong W (2019) Biomethane production from lignocellulose: biomass recalcitrance and its impacts on anaerobic digestion. Front Bioeng Biotechnol 7:1–12. https://doi.org/10.3389/fbioe.2019.00191

Gomec CY, Gonuldinc S, Eldem N, Ozturk I (2005) Behaviour if an up-flow anaerobic sludge bed reactor (UASB) reactor at extreme salinity. Water Sci Technol 51:115–120. https://doi.org/10.2166/wst.2005.0397

Moon C, Singh R, Veeravalli SS, Shanmugam SR, Chaganti SR, Lalman JA, Heath DD (2015) Effect of COD:SO42− ratio, HRT and linoleic acid concentration mesophilic sulfate reduction: reactor performance and microbial population dynamics. Water 7:2275–2292. https://doi.org/10.3390/w7052275

Damianovic MHRZ, Saia FT, Gouvêa de Godoi LA, Foresti E (2016) Long-term operation of anaerobic immobilized biomass reactor treating organic wastewater containing sulfate. J Water Process Eng 13:100–106. https://doi.org/10.1016/j.jwpe.2016.08.009

Mischopoulou M, Kalamaras SD, Naidis P, Kotsopoulos TA, Samaras P (2017) Start-up and steady-state results of a UASB reactor treating high pH baker’s yeast molasses wastewater for methane production. J Chem Technol Biotechnol 92:775–780. https://doi.org/10.1002/jctb.5055

Bakraoui M, Karouach F, Ouhammou B, Aggour M, Essamri A, El Bari H (2020) Biogas production from recycled paper mill wastewater by UASB digester: optimal and mesophilic conditions. Biotechnol Rep 25:e00402. https://doi.org/10.1016/j.btre.2019.e00402

Magowo WE, Sheridan C, Rumbold K (2020) Global co-occurrence of acid mine drainage and organic rich industrial and domestic effluent: biological sulfate reduction as a co-treatment-option. J Water Process Eng 38:101650. https://doi.org/10.1016/j.jwpe.2020.101650

Mainardis M, Buttazzoni M, Goi D (2020) Up-flow anaerobic sludge blanket (UASB) technology for energy recovery: a review on state-of-the-art and recent technological advances. Bioengineering (Basel, Switzerland) 7:43. https://doi.org/10.3390/bioengineering7020043

Hendrickx TLG, Pessotto B, Prins R, Habets L, Vogelaar J (2019) Biopaq®ICX: the next generation high rate anaerobic reactor proves itself at full scale. Water Pract Technol 14:802–807. https://doi.org/10.2166/wpt.2019.066

Yang MI (2015) The effect of anaerobic treatment of pulp mill effluents on reactor performance and granular sludge. Dissertation, University of Toronto

Crater JS, Lievense JC (2018) Scale-up of industrial microbial processes. FEMS Microbiol Lett 365(13):fny138. https://doi.org/10.1093/femsle/fny138

Tsoy N, Steubing B, van der Giesen C, Guinée J (2020) Upscaling methods used in ex ante life cycle assessment of emerging technologies: a review. Int J Life Cycle Assess 25:1680–1692. https://doi.org/10.1007/s11367-020-01796-8

Piccinno F, Hischier R, Seeger S, Som C (2016) From laboratory to industrial scale: a scale-up framework for chemical processes in life cycle assessment studies. J Clean Prod 135:1085–1097. https://doi.org/10.1016/j.jclepro.2016.06.164

Bakraoui M, El Gnaoui Y, Lahboubi N, Karouach F, El Bari H (2020) Kinetic study and experimental productions of methane production from UASB reactor treating wastewater from recycled pulp and paper for the continuous test. Biomass Bioenergy 139:105604. https://doi.org/10.1016/j.biombioe.2020.105604

Pekyavas G, Dereli RK, Yangin-Gomec C (2020) Comparative assessment of modeling and experimental data of ammonia removal from pre-digested chicken manure. J Environ Sci Health - Part A Toxic/Hazard Subst Environ Eng 55:1–6. https://doi.org/10.1080/10934529.2020.1794206

Henze M, Gujer W, Mino T, Matsuo T, Wentzel MC, Marais G (1986) Activated sludge model number 1. Scientific and Tech. Reports No. 1, IAWPRC

Henze M, Gujer W, Mino T, van Loosdrecht MCM (2000) Activated sludge models ASM1, ASM2, ASM2d and ASM3. IWA publishing, London

Karahan-Gül Ö, van Loosdrecht MCM, Orhon D (2003) Modification of activated sludge model no. 3 considering direct growth on primary substrate. Water Sci Technol 47:219–225. https://doi.org/10.2166/wst.2003.0608

Iacopozzi I, Innocenti V, Marsili-Libelli S, Giusti E (2007) A modified activated sludge model no. 3 (ASM3) with two-step nitrification–denitrification. Environ Model Softw 22:847–861. https://doi.org/10.1016/j.envsoft.2006.05.009

Hydromantis, Inc. (2021) Library of models. https://www.hydromantis.com/GPSX-models.html. Accessed Feb 2021

Yarsur E (2021) Biogas recovery during anaerobic treatment of lignocellulose-rich pollutants with high sulfate content: an investigation via innovative applications. Istanbul Technical University, Dissertation

APHA (2005) Standard methods for the examination of water and wastewater. American Public Health Association/American Water Works Association/Water Environment Federation, Washington D.C.

SciPy (2021) SciPy.org. https://www.scipy.org. Accessed Jan 2021

Gomec CY, Kim M, Ahn Y, Speece RE (2002) The role of pH in mesophilic anaerobic sludge solubilization. J Environ Sci Health A 37:1871–1878. https://doi.org/10.1081/ESE-120015467

Elmitwalli T (2013) Mathematical modeling of upflow anaerobic sludge blanket (UASB) reactor treating domestic wastewater. Water Sci Technol 67:24–32. https://doi.org/10.2166/wst.2012.512

Gao M, Guo B, Zhang L, Zhang Y, Yu N, Liu Y (2020) Biomethane recovery from source-diverted household Blackwater: impacts from feed sulfate. Process Saf Environ Prot 136:28–38. https://doi.org/10.1016/j.psep.2020.01.010

Callejas C, López I, Bovio-Winkler P, Etchebehere C, Borzacconi L (2021) Temporal analysis of the microbiota involved in the anaerobic degradation of sugarcane vinasse in a full-scale methanogenic UASB reactor. Biomass Convers Bioref. https://doi.org/10.1007/s13399-021-01281-8

Lopes SIC, Capela MI, Lens PNL (2010) Sulfate reduction during the acidification of sucrose at pH 5 under thermophilic (55 °C) conditions. II: effect of sulfide and COD/ SO42- ratio. Bioresour Technol 101:4278–4284. https://doi.org/10.1016/j.biortech.2010.01.010

Rao AG, Bapat AN (2006) Anaerobic treatment of pre-hydrolysate liquor (PHL) from a rayon grade pulp mill: pilot and full-scale experience with UASB reactors. Bioresour Technol 97:2311–2320. https://doi.org/10.1016/j.biortech.2005.10.033

Chinneraj S, Rao V (2006) Implementation of a UASB anaerobic digester at bagasse-based pulp and paper industry. Biomass Bioenergy 30:273–277. https://doi.org/10.1016/j.biombioe.2005.10.007

Li W, Khalid H, Amin FR, Zhang H, Dai Z, Chen C, Liu G (2020) Biomethane production characteristics, kinetic analysis, and energy potential of different paper wastes in anaerobic digestion. Renew Energy 157:1081–1088. https://doi.org/10.1016/j.renene.2020.04.035

Marshman DJ, Chmelyk T, Sidhu MS, Gopaluni RB, Dumont GA (2010) Energy optimization in a pulp and paper mill cogeneration facility. Appl Energy 87:3514–3525. https://doi.org/10.1016/j.apenergy.2010.04.023

Yangin-Gomec C, Ozturk I (2013) Effect of maize silage addition on biomethane recovery from mesophilic co-digestion of chicken and cattle manure to supress ammonia inhibition. Energy Convers Manag 71:92–100. https://doi.org/10.1016/j.enconman.2013.03.020

Kamali M, Gameiro T, Costa MEV, Capela I (2016) Anaerobic digestion of pulp and paper mill wastes – an overview of the developments and improvement opportunities. Chem Eng J 298:162–182. https://doi.org/10.1016/j.cej.2016.03.119

Enitan AM, Adeyemo J, Swalaha FM, Kumari S, Bux F (2017) Optimization of biogas generation using anaerobic digestion models and computational intelligence approaches. Rev Chem Eng 33:309–335. https://doi.org/10.1515/revce-2015-0057

Silva F, Nadais H, Prates A, Arroja L, Capela I (2009) Modelling of anaerobic treatment of evaporator condensate (EC) from a sulfite pulp mill using the IWA anaerobic digestion model no. 1 (ADM1). Chem Eng J 148:319–326. https://doi.org/10.1016/j.cej.2008.09.002

Lopes ADCP, Silva CM, Rosa AP, Rodrigues FDÁ (2018) Biogas production from thermophilic anaerobic digestion of Kraft pulp mill sludge. Renew Energy 124:40–49. https://doi.org/10.1016/j.renene.2017.08.044

Ahmed B, Tyagi VK, Khan AA, Kazmi AA (2020) Optimization of process parameters for enhanced biogas yield from anaerobic co-digestion of OFMSW and bio-solids. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-020-00919-3

Zaied BK, Rashid M, Nasrullah M, Bari BS, Zularisam AW, Singh L, Kumar D, Krishnan S (2020) Prediction and optimization of biogas production from POME co-digestion in solar bioreactor using artificial neural network coupled with particle swarm optimization (ANN-PSO). Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-020-01057-6

Okwu MO, Samuel OD, Otanocha OB, Tartibu LK, Omoregbee HO, Mbachu VM (2020) Development of ternary models for prediction of biogas yield in a novel modular biodigester: a case of fuzzy Mamdani model (FMM), artificial neural network (ANN), and response surface methodology (RSM). Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-020-01113-1

Hu C, Yan B, Wang KJ, Xiao XM (2018) Modeling the performance of anaerobic digestion reactor by the anaerobic digestion system model (ADSM). J Environ Chem Eng 6:2095–2104. https://doi.org/10.1016/j.jece.2018.03.018

Li H, Chen Z, Fu D, Wang Y, Zheng Y, Li Q (2020) Improved ADM1 for modelling C, N, P fates in anaerobic digestion process of pig manure and optimization approaches to biogas production. Renew Energy 146:2330–2336. https://doi.org/10.1016/j.renene.2019.08.086

Yetilmezsoy K (2012) Integration of kinetic modeling and desirability function approach for multi-objective optimization of UASB reactor treating poultry manure wastewater. Bioresour Technol 118:89–101. https://doi.org/10.1016/j.biortech.2012.05.088

Rizwan M, Almansoori A, Elkamel A (2019) An overview on synthesis and design of microalgal biorefinery configurations by employing superstructure-based optimization approach. Energy Syst 10:941–966. https://doi.org/10.1007/s12667-018-0296-6

Acknowledgements

The Department of Scientific Research Projects of ITU (Project Number: MYL-2019-42365) is acknowledged. Moreover, authors are grateful to Prof. Izzet Ozturk and Res. Ass. Hazal Gulhan for their kind assistance.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yangin-Gomec, C., Yarsur, E. & Ozcan, O.Y. Energy recovery during anaerobic treatment of lignocellulosic wastewater with dynamic modeling and simulation results. Biomass Conv. Bioref. 13, 9227–9236 (2023). https://doi.org/10.1007/s13399-021-01757-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01757-7