Abstract

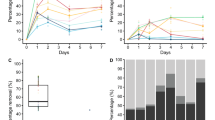

Environmental pollution is a serious concern within the Mediterranean area, this situation results mainly from olive mill wastewaters (OMW), the liquid effluents generated during olive oil extraction. Anaerobic digestion of olive mill wastewaters is negatively affected by nitrogen deficiency, low pH, and the presence of phenolic compounds. This study examines the feasibility of OMW co-digestion with rich nitrogen substrates in batch and continuous mode under mesophilic conditions. Four substrates were tested at different ratios (substrate/OMW) in batch mode. Optimal ratio (substrate/OMW) was 80:20 for poultry manure (PM), 20:80 for both cheese whey (CW) and grass, and 50:50 for slaughterhouse wastewater (SWW). Furthermore, the effect of organic loading rate was assessed in continuous mode, using an anaerobic sequencing batch reactor for the mix (SWW/OMW) at 50:50. The reactor was able to degrade 10 g COD/L/day, as the maximal limit for biogas production and process stability. The results proved that co-digestion of SWW with OMW at 50:50 produced the higher biogas volume in batch mode and ensure good process stability, expressed by high alkalinity (2150 eq mg CaCo3/L) and low rate of volatile fatty acids (VFA) (150 eq mg acetic acid/L). Co-digestion of OMW with SWW is an efficient solution, to solve environmental pollution and recover renewable energy from these two organic wastes.

Similar content being viewed by others

References

Achak M, Ouazzani N, Yaacoubi A, Mandi L (2008) Caractérisation des margines issues d’une huilerie moderne et essais de leur traitement par coagulation-floculation par la chaux et le sulfate d’aluminium. Rev Des Sci De L'Eau 21:53–67

Caporaso N, Formisano D, Genovese A (2018) Use of phenolic compounds from olive mill wastewater as valuable ingredients for functional foods. Crit Rev Food Sci Nutr 58:2829–2841

Esmail A, Abed H, Firdaous M, Chahboun N, Mennane Z, Berny Hassan E, Ouhssine M (2014) Physico-chemical and microbiological study of oil mill wastewater (OMW) from three different regions of Morocco (Ouazzane, Fes Boulman and Beni Mellal). J Mater Environ Sci 5:121–126

El Hassani FZ, Zinedine A, Alaoui SM, Merzouki M, Benlemlih M (2010) Use of olive mill wastewater as an organic amendment for Mentha spicata L. Ind Crop Prod 32:343–348

Aissam H, Penninckx MJ, Benlemlih M (2007) Reduction of phenolic content and COD in olive oil mill wastewaters by indigenous yeasts and fungi. World J Microbiol Biotechnol 23:1203–1208

Scoma A, Bertin L, Fava F (2013) Effect of hydraulic retention time on biohydrogen and volatile fatty acids production during acidogenic digestion of dephenolized olive mill wastewaters. Biomass Bioenergy 48:51–58

Sarris D, Rapti A, Papafotis N, Koutinas AA, Papanikolaou S (2019) Production of added-value chemical compounds through bioconversions of olive-mill wastewaters blended with crude glycerol by a Yarrowia lipolytica strain. Molecules 24:222

Dermeche S, Nadour M, Larroche C, Moulti-Mati F, Michaud P (2013) Olive mill wastes: biochemical characterizations and valorization strategies. Process Biochem 48(10):1532–1552

Ahmed PM, Fernández PM, de Figueroa LI, Pajot HF (2019) Exploitation alternatives of olive mill wastewater: production of value-added compounds useful for industry and agriculture. Biofuel Res J 6(2):980–994

Beniche I, Hungría J, El Bari H, Siles JA, Chica AF, Martín MA (2020) Effects of C/N ratio on anaerobic co-digestion of cabbage, cauliflower, and restaurant food waste. Biomass Convers Biorefin:1–13

Messineo A, Maniscalco MP, Volpe R (2019) Biomethane recovery from olive mill residues through anaerobic digestion: a review of the state of the art technology. Sci Total Environ 703:135508

Kumar A, Samadder SR (2020) Performance evaluation of anaerobic digestion technology for energy recovery from organic fraction of municipal solid waste: a review. Energy 197:117253

Dareioti MA, Dokianakis SN, Stamatelatou K, Zafiri C, Kornaros M (2010) Exploitation of olive mill wastewater and liquid cow manure for biogas production. Waste Manag 30:1841–1848

Siciliano A, Stillitano MA, De Rosa S (2016) Biogas production from wet olive mill wastes pretreated with hydrogen peroxide in alkaline conditions. Renew Energy 85:903–916

Gonçalves MR, Freitas P, Marques IP (2012) Bioenergy recovery from olive mill effluent in a hybrid reactor. Biomass Bioenergy 39:253–260

Khoufi S, Louhichi A, Sayadi S (2015) Optimization of anaerobic co-digestion of olive mill wastewater and liquid poultry manure in batch condition and semi-continuous jet-loop reactor. Bioresour Technol 182:67–74

Rodier J (2009) L’analyse de l’eau : eaux naturelles, eaux résiduaires, eau de mer. Dunod, Paris

Sounni F, Aissam H, Ghomari O, Merzouki M, Benlemlih M (2018) Electrocoagulation of olive mill wastewaters to enhance biogas production. Biotechnol Lett 40:297–301

Kougias PG, Kotsopoulos TA, Martzopoulos GG (2014) Effect of feedstock composition and organic loading rate during the mesophilic co-digestion of olive mill wastewater and swine manure. Renew Energy 69:202–207

Ammary BY (2005) Treatment of olive mill wastewater using an anaerobic sequencing batch reactor. Desalination 177:157–165

Dalkılıc K, Ugurlu A (2015) Biogas production from chicken manure at different organic loading rates in a mesophilic-thermophilic two stage anaerobic system. J Biosci Bioeng 120:315–322

Caixeta CE, Cammarota MC, Xavier AM (2002) Slaughterhouse wastewater treatment: evaluation of a new three-phase separation system in a UASB reactor. Bioresour Technol 81:61–69

Xie SP, Lawlor G, Frost JP, Hu Z, Zhan X (2011) Effect of pig manure to grass silage ratio on methane production in batch anaerobic co-digestion of concentrated pig manure and grass silage. Bioresour Technol 102:5728–5757

Gelegenis J, Georgakakis D, Angelidaki I, Christopoulou I, Goumenaki M (2007) Optimization of biogas production from olive-oil mill wastewater by codigesting with diluted poultry-manure. Appl Energy 84:646–663

Azbar N, Keskin T, Yuruyen A (2008) Enhancement of biogas production from olive mill effluent (OME) by co-digestion. Biomass Bioenergy 32:1195–1201

Martinez-Garcia G, Johnson AC, Bachmann RT, Williams CJ, Burgoyne A, Edyvean RGJ (2007) Two-stage biological treatment of olive mill wastewater with whey as co-substrate. Int Biodeterior Biodegradation 59:273–282

Dareioti MA, Dokianakis SN, Stamatelatou K, Zafiri C, Kornaros M (2009) Biogas production from anaerobic co-digestion of agro industrial wastewaters under mesophilic conditions in a two-stage process. Desalination 248:891–906

Prazeres AR, Carvalho F, Rivas J (2012) Cheese whey management: a review. J Environ Manag 110:48–68

Liew LN, Shi J, Li Y (2012) Methane production from solid-state anaerobic digestion of lignocellulosic biomass. Biomass Bioenergy 46:125–132

Goberna M, Schoen MA, Sperl D, Wett B, Insam H (2010) Mesophilic and thermophilic co-fermentation of cattle excreta and olive mill wastes in pilot anaerobic digesters. Biomass Bioenergy 34:340–346

Gannoun H, Omri I, Chouari R, Khelifi E, Godon JJ, Hamdi M, Bouallagui H (2016) Microbial community structure associated with the high loading anaerobic co-digestion of olive mill and abattoir wastewaters. Bioresour Technol 201:337–346

Massé DI, Masse L (2001) The effect of temperature on slaughterhouse wastewater treatment in anaerobic sequencing batch reactors. Bioresour Technol 76:91–98

Siegert I, Banks C (2005) The effect of volatile fatty acid additions on the anaerobic digestion of cellulose and glucose in batch reactors. Process Biochem 40:3412–3418

Fezzani B, Cheikh RB (2010) Two-phase anaerobic co-digestion of olive mill wastes in semi-continuous digesters at mesophilic temperature. Bioresour Technol 101:1628–1634

Fountoulakis MS, Drakopoulou S, Terzakis S, Georgaki E, Manios T (2008) Potential for methane production from typical Mediterranean agro-industrial by-products. Biomass Bioenergy 32:155–161

Boubaker F, Ridha BC (2007) Anaerobic co-digestion of olive mill wastewater with olive mill solid waste in a tubular digester at mesophilic temperature. Bioresour Technol 98:769–774

Pishgar R, Najafpour GD, Neya BN (2014) Effects of organic loading rate and hydraulic retention time on treatment of phenolic wastewater in an anaerobic immobilized fluidized bed reactor. J Environ Eng Landsc 22:40–49

Mudhoo A, Kumar S (2013) Effects of heavy metals as stress factors on anaerobic digestion processes and biogas production from biomass. Int J Environ Sci Te 10:1383–1398

Nkoa R (2014) Agricultural benefits and environmental risks of soil fertilization with anaerobic digestates: a review. Agron Sustain Dev 34:473–492

Pivato A, Vanin S, Raga R, Lavagnolo MC, Barausse A, Rieple A, Cossu R (2016) Use of digestate from a decentralized on-farm biogas plant as fertilizer in soils: an ecotoxicological study for future indicators in risk and life cycle assessment. Waste Manag 49:378–389

Song Z, Fang L, Wang J, Zhang C (2019) Use of biogas solid residue from anaerobic digestion as an effective amendment to remediate Cr (VI)-contaminated soils. Environ Sci Pollut Res 26:13041–13053

Acknowledgements

A part of this study was supported by the research project “Etude des Technologies Appropriées pour La Conversion des Déchets Organiques et Biomasse en Energie Renouvelable et en Biofertilisant Durables” MESRSFC and CNRST-Morocco

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sounni, F., Elgnaoui, Y., El Bari, H. et al. Effect of mixture ratio and organic loading rate during anaerobic co-digestion of olive mill wastewater and agro-industrial wastes. Biomass Conv. Bioref. 13, 1223–1229 (2023). https://doi.org/10.1007/s13399-021-01463-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01463-4