Abstract

New demands placed on industry make it necessary to improve design, real-time monitoring and failure prediction methods for rolling bearings. This paper presents an approach for assessing how contact surface damage affects the vibration response of rolling bearings and how vibration-based monitoring shows the damage level of rolling element bearings. A new parameter named the damage factor is introduced to quantify the vibration response of rolling bearings. The analytical–numerical method for calculation of this parameter is developed based on nonlinear dynamics postulates. The developed method for damage factor calculation is tested on a particular type of radial deep groove ball bearing, and an experimental verification is performed, showing a maximum deviation of 7% in the results. The conclusions drawn from the obtained results and the potential contributions of the introduced parameters for rolling bearing design are discussed. The chosen polynomial function keeps deviations in relation to the calculated damage factor within 3% for failed areas of different sizes.

Similar content being viewed by others

Abbreviations

- A d :

-

Maximum vibration amplitude of a damaged bearing, m/s2

- A u :

-

Vibration amplitude of an undamaged bearing, m/s2

- B :

-

Bearing width, m

- C :

-

Dynamic load capacity, N

- C 0 :

-

Static load capacity, N

- C(t):

-

Damping matrix

- C r :

-

Radial deep groove ball bearing damping, N s/m

- D :

-

Bearing outer race diameter, m

- d :

-

Bearing inner race diameter, m

- d 0 :

-

Average diameter of damages for particular rolling bearing type (obtained empirically), m

- d b :

-

Diameter of bearing rolling elements, m

- d c :

-

Diameter of the dividing axis of the bearing cage, m

- d d :

-

Diameter of damage on a contact surface, m

- d i :

-

Diameter of the inner race, m

- d o :

-

Diameter of the outer race, m

- E :

-

Young's modulus, N/m2

- F(t):

-

Vector of external forces

- F :

-

External load, N

- F δ :

-

Load distributed on the most loaded rolling element, N

- f i :

-

Specific inner ring frequency, Hz

- K(t):

-

Stiffness matrix

- K r :

-

Radial deep grove ball bearing stiffness, N/m

- K V :

-

Damage factor

- M(t):

-

Mass matrix

- m red :

-

Reduced mass of system shaft-bearing-casing, kg

- n :

-

Rotational velocity, rpm

- Q(t):

-

Vector of nonlinearity coefficient

- q :

-

Nonlinearity coefficient, N/m3

- r ti :

-

Inner ring groove radius, m

- r to :

-

Outer ring groove radius, m

- t :

-

Time, s

- y(t):

-

Vector of the generalized displacement

- y :

-

Displacement in radial direction, m

- z :

-

Total number of rolling elements

- α :

-

Bearing contact angle, degrees

- γ :

-

Angular distance between rolling elements, degrees

- δ :

-

Local contact deformation on the most loaded rolling element and raceway surface with damage, m

- ε :

-

Total radial displacement of axis of bearing in radial direction, m

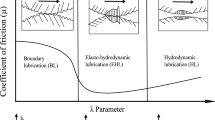

- µ :

-

Friction coefficient in contact zones

- µ m :

-

Poisson’s ratio

- ω :

-

Angular velocity, s−1

References

Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A.: Sustainable Industry 4.0 framework: a systematic literature review identifying the current trends and future perspectives. Process Saf. Environ. Prot. 117, 408–425 (2018). https://doi.org/10.1016/j.psep.2018.05.009

Vaidya, S.; Ambad, P.; Bhosle, S.: Industry 4.0—a glimpse. Proc. Manuf. 20, 233–238 (2018). https://doi.org/10.1016/j.promfg.2018.02.034

Hamrol, A.; Gawlik, J.; Sładek, J.: Mechanical engineering in Industry 4.0. Manag. Prod. Eng. Rev. 10(3), 14–28 (2019). https://doi.org/10.24425/mper.2019.129595

Mitrovic, R., Atanasovska, I., Soldat, N., Miskovic, Z.: New Trends in Machine Design within Industry 4.0 Framework. AMP 2020, LNME, pp. 227–238 (2020). Doi: https://doi.org/10.1007/978-3-030-46212-3_16

Toh, G.; Park, J.: Review of Vibration-Based Structural Health Monitoring Using Deep Learning. Appl. Sci. 10, 1680 (2020). https://doi.org/10.3390/app10051680

de Azevedo, H.D.M., et al.: "Vibration monitoring, fault detection, and bearings replacement of a real wind turbine. J Braz Soc. Mech. Sci. Eng. 39, 3837–3848 (2017). https://doi.org/10.1007/s40430-017-0853-2

Bo Luo, B.; Wang, H.; Liu, H.; Li, B.; Peng, F.: Early fault detection of machine tools based on deep learning and dynamic identification. IEEE Trans. Industr. Electron. 15,(2018). https://doi.org/10.1109/TIE.2018.2807414

Machado, C., et al.: Diagnosis of faults in the bearings by electrical measures and numerical simulations. Mech. Ind. 15, 383–391 (2014). https://doi.org/10.1051/meca/2014053

Fang, B.; Zhang, J.; Wan, S.; Hong, J.: Determination of optimum preload considering the skidding and termal characteristic of high-speed angular contact ball bearing. ASME J Mech Design 140, 053301–053311 (2018). https://doi.org/10.1115/1.4039386

Fang, B.; Wan, S.; Zhang, J.; Hong, J.: Research on the influence of clearance variation on the stiffness fluctuation of ball bearing under different operating conditions. ASME J Mech Design 10(1115/1), 4047903 (2020)

Fingerle, A.; Hochrein, J.; Otto, M.; Stahl, K.: Theoretical study on the influence of planet gear rim thickness and bearing clearance on calculated bearing life. ASME J Mech Design 142, 031102–031111 (2020). https://doi.org/10.1115/1.4045244

Harris, T.A., Kotzalas, M.N., 2007, "Rolling Bearing Analysis", Taylor&Franciz Group, SAD, ISBN 9781482275148

Tandon, N.; Choudhury, A.: A review of vibration and acoustic measurementmethods for the detection of defects in rolling element bearings. Tribol. Int. 32, 469–480 (1999). https://doi.org/10.1016/S0301-679X(99)00077-8

Tandon, N.; Choudhury, A.: An analytical model for the prediction of the vibration response of rolling element bearings due to a localized defect. J. Sound Vib. 205(3), 275–292 (1997). https://doi.org/10.1006/jsvi.1997.1031

Sopanen, J., Mikola, A.: Dynamic model of a deep-groove ball bearing including localized and distributed defects—part1: theory. In: Proceedings of the institution of mechanical engineers K—journal of multi-body dynamics, 217, pp. 201–211 (2003). Doi: https://doi.org/10.1243/14644190360713551

Petersen, D.; Howard, C.; Sawalhi, N.; Ahmadi, A.M.; Singh, S.: Analysis of bearing stiffness variations, contact forces and vibrations in radially loaded double row rolling element bearings with raceway defects. Mech. Syst. Signal Process. 50–51, 139–160 (2015). https://doi.org/10.1016/j.ymssp.2014.04.014

Petersen, D.; Howard, C.; Prime, Z.: Varying stiffness and load distributions in defective ball bearings: analytical formulation and application to defect size estimation. J. Sound Vib. 337, 284–300 (2015). https://doi.org/10.1016/j.jsv.2014.10.004

Malhi, A.C.: Finite element modeling of vibrations caused by a defect in the outer ring of a ball bearing. Project Rep. Finite Element Method Appl. MIE 605, 2002 (2002)

Kulkarni, S., Wadkar, S.B.: Experimental investigation for distributed defects in ball bearing using vibration signature analysis. In: 12th International Confer9ence on Vibration Problems, ICOVP 2015,Procedia Engineering, 144, pp. 781–789 (2016). Doi: https://doi.org/10.1016/j.proeng.2016.05.086

Leturiondo, U.; Salgado, O.; Galar, D.: Validation of a physics-based model for rolling element bearings with diagnosis purposes. In: 8th European Workshop on Structural Health Monitoring (EWSHM 2016). Spain. 5–8 July 2016. (2016)

Leturiondo, U., Salgado, O., Galar D.: Multi-body modelling of rolling element bearings and performance evaluation with localised damage. In: Eksploatacja i Niezawodnosc—Maintenance and Reliability, 18(4), 638–648 (2016). Doi: https://doi.org/10.17531/ein.2016.4.20

Shaikh, C.; Kulkarni, C.: A theoretical model for predicting the vibration response of outer race defective ball bearing. Int. J. Eng. Technol. 7(2), 289–295 (2018). https://doi.org/10.14419/ijet.v7i2.8953

Delprete, C.; Brusa, E.; Rosso, C.; Bruzzone, F.: Bearing health monitoring based on the orthogonal empirical mode decomposition. Shock Vib. 8761278 (2020). https://doi.org/10.1155/2020/8761278

Ye, L.; Xia, X.; Chang, Z.: Dynamic prediction of the performance reliability of high-speed railway bearings. J. Braz. Soc. Mech. Sci. Eng. 41, 532 (2019). https://doi.org/10.1007/s40430-019-2041-z

Tingarikar, G.; Choudhury, A.: Vibration analysis-based fault diagnosis of a dynamically loaded bearing with distributed defect. Arab. J. Sci. Eng. (2021). https://doi.org/10.1007/s13369-021-05862-7

Boumahdi, M.; Rechak, S.; Hanini, S.: Analysis and prediction of defect size and remaining useful life of thrust ball bearings: modelling and experiment procedures. Arab. J. Sci. Eng. 42, 4535–4546 (2017). https://doi.org/10.1007/s13369-017-2550-y

Pinedo-Sanchez, L.A.; Mercado-Ravell, D.A.; Carballo-Monsivais, C.A.: Vibration analysis in bearings for failure prevention using CNN. J. Braz. Soc. Mech. Sci. Eng. 42, 628 (2020). https://doi.org/10.1007/s40430-020-02711-w

Soldat, N.; Mitrovic, R.; Atanasovska, I.; Tomovic, R.: A methodology for analyzing radial ball bearing vibrations. Transactions of FAMENA 44(1), 13–28 (2020). https://doi.org/10.21278/TOF.44102

Patel, V.N.; Tandon, N.; Pandey, R.K.: experimental study for vibration behaviors of locally defective deep groove ball bearings under dynamic radial load. Adv. Acoust. Vib. Article ID 271346 (2014). https://doi.org/10.1155/2014/271346

Kumbhar, S.G.; Desavale, R.G.; Shinde, A.A.: Theoretical and experimental studies on vibrations produced by defects in taper roller bearing using vibration signature analysis. Int J. Eng. Res. Technol. JERT 3(5), 1270–1283 (2014)

Kulkarni, P.G.; Sahasrabudhe, A.D.: A dynamic model of ball bearing for simulating localized defects on outer race using cubic hermite spline. J. Mech. Sci. Technol. 28(9), 3433–3442 (2014). https://doi.org/10.1007/s12206-014-0804-0

Ding, W., Zhang, Z., and Zhao, F.,: Vibration response of ball bearings with different defect sizes in the outer raceway: Simulation with a 3-D finite element model. In: The 14th IFToMM World Congress, Taipei, Taiwan, October 25–30, (2015). Doi: https://doi.org/10.6567/IFToMM.14TH.WC.OS14.005

Kulkarni, S.; Bewoor, A.: Analysis of distributed defect on outer ring of ball bearing under radial load: a theoretical and experimental approach. J. Eng. Sci. Technol. 13(11), 3764–3780 (2018)

Atanasovska, I., Mitrovic, R., Soldat, N, and Momcilovic, D.: Finite element model for stress state analysis of deep groove ball bearing with defects. In: Proceedings of the 5rd International Scientific Conference “Conference on Mechanical Engineering Technologies and Applications”—COMETA920202020, November 26–28, 2020, East Sarajevo, ISBN 978–99976–719–8–1, pp. 285–292 (2020)

Atanasovska, I.: Multi-body contact in non-linear dynamics of real mechanical systems. Proc. Eng. 199, 510–515 (2017). https://doi.org/10.1016/j.proeng.2017.09.139

Atanasovska, I., Momcilovic, D., Mitrovic, R., Soldat, N., and Nesic, N.: Nonlinear dynamics as a tool in selection of working conditions for radial ball bearing. In: IUTAM Bookseries 37 - IUTAM Symposium on Exploiting Nonlinear Dynamics for Engineering Systems, pp.49–58 (2020). Doi: https://doi.org/10.1007/978-3-030-23692-2_5

Demirhan, N.; Kanber, B.: Stress and displacement distributions on cylindrical roller bearing rings using FEM. Mech. Based Des. Struct. Mach. 36, 86–102 (2008). https://doi.org/10.1080/15397730701842537

Ashtekar, A.; Sadeghi, F.; Stacke, L.-E.: a new approach to modeling surface defects in bearing dynamics simulations. ASME J Tribol 130, 041103–041111 (2008). https://doi.org/10.1115/1.2959106

Niu, L.: A simulation study on the effects of race surface waviness on cage dynamics in high-speed ball bearings. ASME J Tribol 141, 051101–051111 (2019). https://doi.org/10.1115/1.4042656

Atanasovska, I.: The mathematical phenomenological mapping in nonlinear dynamics of spur gear pair and radial ball bearing due to the variable stiffness. Int. J. Non-Linear Mech. 73, 114–120 (2015). https://doi.org/10.1016/j.ijnonlinmec.2014.11.015

Atanasovska, I., Mitrovic, R. Soldat, N.: Influence of load distribution in ball bearings with defects on the dynamic behavior of gear transmissions systems. In: International Conference on GEARS 2015, Garching (near Munich), Germany, pp. 1065–1068 (2015)

Cheng, H., et al.: Research on the effect of structural and material parameters on vibrations based on quasi-static model of bearings. J. Braz. Soc. Mech. Sci. Eng. 42, 578 (2020). https://doi.org/10.1007/s40430-020-02659-x

Boveta, C.; Zamponi, L.: An approach for predicting the internal behaviour of ball bearings under high moment load. Mech. Mach. Theory 101, 1–22 (2016). https://doi.org/10.1016/j.mechmachtheory.2016.03.002

Cveticanin, L.: Ninety years of Duffings equation. Theoretical and applied mechanics, Series: Special Issue - Address to Mechanics 40(S1), 49–63 (2012). https://doi.org/10.2298/TAM12S149C

Kovacic, I., and Gatti, G.: Helmholtz, Duffing and Helmholtz-Duffing oscillators: exact steady-state solutions. In: IUTAM Bookseries 37—IUTAM Symposium on Exploiting Nonlinear Dynamics for Engineering Systems, pp.167–177 (2020). Doi: https://doi.org/10.1007/978-3-030-23692-2_15

Patel, V.N.; Tandon, N.; Pandey, R.K.: Defect detection in deep groove ball bearing in presence of external vibration using envelope analysis and Duffing oscillator. Measurement 45, 960–970 (2012). https://doi.org/10.1016/j.measurement.2012.01.047

Acknowledgements

We thank the Factory of Rolling Bearings and Cardan Shafts FKL, Temerin, Serbia, for providing the data and producing the samples utilized in this research.

Funding

Parts of the presented research are funded by the Ministry of Education, Science and Technological Development of the Republic of Serbia, through the Mathematical Institute of the Serbian Academy of Sciences and Arts, Belgrade, Serbia, and the Faculty of Mechanical Engineering of University of Belgrade.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Atanasovska, I.D., Soldat, N.D., Patil, S.S. et al. Damage Factor Calculation for Condition Monitoring of Rolling Bearings. Arab J Sci Eng 48, 3181–3194 (2023). https://doi.org/10.1007/s13369-022-07126-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-022-07126-4