Abstract

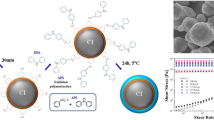

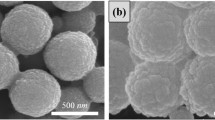

Two different shapes of spherical- and flake-like soft-magnetic carbonyl iron (CI) microparticles were dispersed in silicone oil to prepare magnetorheological (MR) fluids. The magnetic-field dependent rheological behaviors of the MR fluids were scrutinized focusing on their shape effect. Saturation magnetization of the flake-shaped CI was obtained to be slightly lower than that of spherical-shaped CI. However, rheological properties of shear stress, shear viscosity, and storage modulus of the flake-shaped CI MR fluid surpassed those of the spherical-shaped CI MR suspension under applied magnetic field strengths. The flake-shaped CI based MR fluid also demonstrated superior sedimentation stability compared with the spherical-shaped CI. This was due to large surface area, suggesting that the anisotropy of CI particles plays an important role in their MR performance.

Similar content being viewed by others

Explore related subjects

Discover the latest articles and news from researchers in related subjects, suggested using machine learning.References

Ahn, W.J., H.S. Jung, and H.J. Choi, 2015, Pickering emulsion polymerized smart magnetic poly(methyl methacrylate)/Fe2O3 composite particles and their stimulus-response, RSC Adv. 5, 23094–23100.

Ashtiani, M., S.H. Hashemabadi, and A. Ghaffari, 2015, A review on the magnetorheological fluid preparation and stabilization, J. Magn. Magn. Mater. 374, 716–730.

Bell, R.C., E.D. Miller, J.O. Karli, A.N. Vavreck, and D.T. Zimmerman, 2007, Influence of particle shape on the properties of magnetorheological fluids, Int. J. Mod. Phys. B 21, 5018–5025.

Bica, I. and E.M. Anitas, 2018, Magnetic field intensity effect on electrical conductivity of magnetorheological biosuspensions based on honey, turmeric and carbonyl iron, J. Ind. Eng. Chem. 64, 276–283.

Cao, Q., X. Han, and L. Li, 2014, Configurations and control of magnetic fields for manipulating magnetic particles in microfluidic applications: Magnet systems and manipulation mechanisms, Lab Chip 14, 2762–2777.

Claracq, J., J. Sarrazin, and J.P. Montfort, 2004, Viscoelastic properties of magnetorheological fluids, Rheol. Acta 43, 38–49.

de Vicente, J., D.J. Klingenberg, and R. Hidalgo-Alvarez, 2011, Magnetorheological fluids: A review, Soft Matter 7, 3701–3710.

de Vicente, J., F. Vereda, J.P. Segovia-Gutiérrez, M. del Puerto Morales, and R. Hidalgo-Álvarez, 2010, Effect of particle shape in magnetorheology, J. Rheol. 54, 1337–1362.

Emri, I., B.S. von Bernstorff, R. Cvelbar, and A. Nikonov, 2005, Re-examination of the approximate methods for interconversion between frequency-and time-dependent material functions, J. Non-Newton. Fluid Mech. 129, 75–84.

Fang, F.F., M.S. Yang, and H.J. Choi, 2008, Novel magnetic composite particles of carbonyl iron embedded in polystyrene and their magnetorheological characteristics, IEEE Trans. Magn. 44, 4533–4536.

Fang, F.F., Y.D. Liu, H.J. Choi, and Y. Seo, 2011, Core-shell structured carbonyl iron microspheres prepared via dual-step functionality coatings and their magnetorheological response, ACS Appl. Mater. Interfaces 3, 3487–3495.

Gao, C.Y., M.W. Kim, D.H. Bae, Y.Z. Dong, S.H. Piao, and H.J. Choi, 2017, Fe3O4 nanoparticle-embedded polystyrene composite particles fabricated via a Shirasu porous glass membrane technique and their magnetorheology, Polymer 125, 21–29.

Genc, S. and P.P. Phulé, 2002, Rheological properties of magnetorheological fluids, Smart Mater. Struct. 11, 140–146.

Ginder, J.M., L.C. Davis, and L.D. Elie, 1996, Rheology of magnetorheological fluids: Models and measurements, Int. J. Mod. Phys. B 10, 3293–3303.

Jeon, J. and S. Koo, 2012, Viscosity and dispersion state of magnetic suspensions, J. Magn. Magn. Mater. 324, 424–429.

Kim, M.H., K. Choi, J.D. Nam, and H.J. Choi, 2017, Enhanced magnetorheological response of magnetic chromium dioxide nanoparticle added carbonyl iron suspension, Smart Mater. Struct. 26, 095006.

Lee, J.W., K.P. Hong, M.W. Cho, S.H. Kwon, and H.J. Choi, 2015, Polishing characteristics of optical glass using PMMAcoated carbonyl-iron-based magnetorheological fluid, Smart Mater. Struct. 24, 065002.

Li, Y., J. Li, W. Li, and H. Du, 2014, A state-of-the-art review on magnetorheological elastomer devices, Smart Mater. Struct. 23, 123001.

Min, T.H., H.J. Choi, N.H. Kim, K. Park, and C.Y. You, 2017, Effects of surface treatment on magnetic carbonyl iron/polyaniline microspheres and their magnetorheological study, Colloid Surf. A-Physicochem. Eng. Asp. 531, 48–55.

Mohamad, N., Ubaidillah, S.A. Mazlan, F. Imaduddin, S.B. Choi, and I.I.M. Yazid, 2018, A comparative work on the magnetic field-dependent properties of plate-like and spherical iron particle-based magnetorheological grease, PLoS One 13, e0191795.

Park, B.O., B.J. Park, M.J. Hato, and H.J. Choi, 2011, Soft magnetic carbonyl iron microsphere dispersed in grease and its rheological characteristics under magnetic field, Colloid Polym. Sci. 289, 381–386.

Pei, L., H. Pang, X. Ruan, X. Gong, and S. Xuan, 2017, Magnetorheology of a magnetic fluid based on Fe3O4 immobilized SiO2 core-shell nanospheres: Experiments and molecular dynamics simulations, RSC Adv. 7, 8142–8150.

Peng, G.R., W. Li, T.F. Tian, J. Ding, and M. Nakano, 2014, Experimental and modeling study of viscoelastic behaviors of magneto-rheological shear thickening fluids, Korea-Aust. Rheol. J. 26, 149–158.

Seo, Y.P., S. Han, J. Choi, A. Takahara, H.J. Choi, and Y. Seo, 2018, Searching for a stable high-performance magnetorheological suspension, Adv. Mater. 30, 1704769.

Seo, Y.P., S. Kwak, H.J. Choi, and Y. Seo, 2016, Static yield stress of a magnetorheological fluid containing Pickering emulsion polymerized Fe2O3/polystyrene composite particles, J. Colloid Interface Sci. 463, 272–278.

Shilan, S.T., S.A. Mazlan, Y. Ido, A. Hajalilou, B. Jeyadevan, S.B. Choi, and N.A. Yunus, 2016, A comparison of fielddependent rheological properties between spherical and platelike carbonyl iron particles-based magneto-rheological fluids, Smart Mater. Struct. 25, 095025.

Son, K.J., 2018, A discrete element model for the influence of surfactants on sedimentation characteristics of magnetorheological fluids, Korea-Aust. Rheol. J. 30, 29–39.

Tong, Y., X. Dong, and M. Qi, 2017, High performance magnetorheological fluids with flower-like cobalt particles, Smart Mater. Struct. 26, 025023.

Upadhyay, R.V., Z. Laherisheth, and K. Shah, 2014, Rheological properties of soft magnetic flake shaped iron particle based magnetorheological fluid in dynamic mode, Smart Mater. Struct. 23, 015002.

Wang, D.H. and W.H. Liao, 2011, Magnetorheological fluid dampers: A review of parametric modelling, Smart Mater. Struct. 20, 023001.

Wang, D.M., Y.F. Hou, and Z.Z. Tian, 2013, A novel high-torque magnetorheological brake with a water cooling method for heat dissipation, Smart Mater. Struct. 22, 025019.

Xia, Z., X. Wu, G. Peng, L. Wang, W. Li, and W. Wen, 2017, A novel nickel nanowire based magnetorheological material, Smart Mater. Struct. 26, 054006.

Yang, J., H. Yan, J. Dai, Z. Hu, and H. Zhang, 2017, The rheological response of carbonyl iron particles suspended in mineral oil solution of 12-hydroxy stearic acid, J. Rheol. 61, 515–524.

Zhang, H. and M. Widom, 1995, Field-induced forces in colloidal particle chains, Phys. Rev. E 51, 2099–2103.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, J.Y., Kwon, S.H. & Choi, H.J. Magnetorheological characteristics of carbonyl iron microparticles with different shapes. Korea-Aust. Rheol. J. 31, 41–47 (2019). https://doi.org/10.1007/s13367-019-0005-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13367-019-0005-6