Abstract

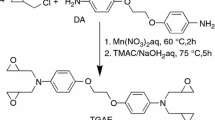

The degradation and recycling of waste epoxy resin products is an urgent environmental problem. To solve this issue, we use acid-/base-degradable 1,1′,1″-(1,3,5-hexahydro-s-triazine-1,3,5-triyl) tris(3-ethylamino-propan-1-one) (TAHT-EA) as curing agent to introduce the hexahydro-s-triazine (HT) ring structure into the cross-linking network to prepare degradable epoxy resin. Specifically, 1,3,5-triacryloylhexahydro-1,3,5-triazine (TAHT) and ethylamine quickly complete the Aza-Michael addition reaction at the interface of chloroform and water droplets under the catalysis of water. The FTIR spectra, NMR spectrum and mass spectrum show that mono- and bis-addition products of ethylamine coexist in the product in which the content of the primary addition product reaches 97%. TAHT-EA can be decomposed by acid and base solutions. Through NMR analysis of the degradation products, it can be explained that the degradation mechanisms are different. The breaking of amide bonds and HT rings in acid solution and the cracking of amide bonds in base solution are speculated to be the main mechanisms under these two different circumstances, respectively. We tested the mechanical, thermal and degradation properties of the epoxy resin cured by TAHT-EA, and compared it with the epoxy resin cured by 4,4′-diaminodiphenylmethane and triethylenetetramine. TAHT-EA-cured epoxy resin shows comparable mechanical properties with Young’s modulus up to 2.05 GPa and tensile strength up to 70.9 MPa. What is more, it degrades completely by 1 M H+/OH− solution at 60 °C within 36 h. Nevertheless, it exhibited a relatively low crosslinked density (633 mol/m3) and low heat resistance (the initial decomposition temperature is lower than 205 °C). Overall, TAHT-EA cured epoxy resin has the potential to gradually replace traditional thermosetting resin, thereby solving the environmental problems caused by discarded epoxy resin products.

Similar content being viewed by others

References

L. M. Johnson, E. Ledet, N. D. Huffman, S. L. Swarner, S. D. Shepherd, P. G. Durham, and G. D. Rothrock, Polymer, 64, 84 (2015).

A. Takahashi, T. Ohishi, R. Goseki, and H. Otsuka, Polymer, 82, 319 (2016).

Z.-J. Li, J. Zhong, M.-C. Liu, J.-C. Rong, K. Yang, J.-Y. Zhou, L. Shen, F. Gao, and H.-F. He, Chin. J. Polym. Sci., 38, 932 (2020).

B. Louage, Q. Zhang, N. Vanparijs, L. Voorhaar, S. V. Casteele, Y. Shi, W. E. Hennink, J. Van Bocxlaer, R. Hoogenboom, and B. G. De Geest, Biomacromolecules, 16, 336 (2015).

T. Hashimoto, H. Meiji, M. Urushisaki, T. Sakaguchi, K. Kawabe, C. Tsuchida, and K. Kondo, J. Polym. Sci. Part A: Polym. Chem., 50, 3674 (2012).

A. Yamaguchi, T. Hashimoto, Y. Kakichi, M. Urushisaki, T. Sakaguchi, K. Kawabe, K. Kondo, and H. Iyo, J. Polym. Sci. Part A: Polym. Chem., 53, 1052 (2015).

Y. Shen, N. Xu, Y. A. Adraro, B. Wang, Y. Liu, W. Yuan, X. Xu, Y. Huang, and Z. Hu, ACS Sustain. Chem. Eng., 8, 1943 (2020).

R. Mo, L. Song, J. Hu, X. Sheng, and X. Zhang, Polym. Chem., 11, 974 (2020).

D. Montarnal, M. Capelot, F. Tournilhac, and L. Leibler, Science, 334, 965 (2011).

L. Yue, V. S. Bonab, D. Yuan, A. Patel, V. Karimkhani, and I. Manas-Zloczower, Global Challenges, 3, 1800076 (2019).

X. Kuang, G. Liu, X. Dong, X. Liu, J. Xu, and D. Wang, J. Polym. Sci. Part A: Polym. Chem., 53, 2094 (2015).

M. Zolghadr, A. Shakeri, M. J. Zohuriaan-Mehr, and A. Salimi, J. Appl. Polym. Sci., 136, 48015 (2019).

J. M. García, G. O. Jones, K. Virwani, B. D. McCloskey, D. J. Boday, G. M. ter Huurne, H. W. Horn, D. J. Coady, A. M. Bintaleb, A. M. S. Alabdulrahman, F. Alsewailem, H. A. A. Almegren, and J. L. Hedrick, Science, 344, 732 (2014).

Y. Yuan, Y. Sun, S. Yan, J. Zhao, S. Liu, M. Zhang, X. Zheng, and L. Jia, Nat. Commun., 8, 14657 (2017).

E. M. Smolin and L. Rapoport, in s-Triazines and Derivatives, W. Arnold, Ed., Interscience Publishers Inc., New York, 1959, pp 533–536.

S. You, S. Ma, J. Dai, Z. Jia, X. Liu, and J. Zhu, ACS Sustain. Chem. Eng., 5, 4683 (2017).

Z. Xu, Y. Liang, X. Ma, S. Chen, C. Yu, Y. Wang, D. Zhang, and M. Miao, Nat. Sustain., 3, 29 (2020).

C. Zhang, Y. Leng, P. Jiang, J. Li, and S. Du, ChemistrySelect, 2, 5469 (2017).

Z. Mao, Z. Li, C. Hu, Y. Liu, Z. Cao, and Z. Chen, J. Chromatogr. A, 1621, 461031 (2020).

L.-Z. Kong and C.-Y. Pan, Polymer, 49, 3450 (2008).

H.-G. Kang, M.-S. Lee, W.-J. Sim, T.-H. Yang, K.-H. Shin, Y.-G. Shul, and Y.-W. Choi, J. Membr. Sci., 460, 178 (2014).

D. M. Lewis and Y. C. Ho, Dyes Pigments, 28, 171 (1995).

D. Wang, Z. Zheng, C. Hong, Y. Liu, and C. Pan, J. Polym. Sci. Part A: Polym. Chem., 44, 6226 (2006).

Z. B. Huang, T. J. Kang, and S. H. Chang, New J. Chem., 29, 1616 (2005).

C. Rim, L. J. Lahey, V. G. Patel, H. Zhang, and D. Y. Son, Tetrahedron Lett., 50, 745 (2009).

V. Kumar, D. Zamora-Olivares, and E. V. Anslyn, Supramol. Chem., 28, 29 (2016).

M. Yoshioka-Tarver, B. D. Condon, M. S. Cintrón, S. Chang, M. W. Easson, C. A. Fortier, C. A. Madison, J. M. Bland, and T.-M. D. Nguyen, Ind. Eng. Chem. Res., 51, 11031 (2012).

B. C. Ranu and S. Banerjee, Tetrahedron Lett., 48, 141 (2007).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Supporting information

Information is available regarding the original data of the Aza-Michael addition reaction in water, and the determination of curing procedure. The materials are available via Internet at http://www.springer.com/13233.

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Acknowledgments: The authors gratefully acknowledge the financial support from the National Natural Science Foundation of China (No. 51903061), the Natural Science Foundation of Guangdong Province (No. 2018A030313239), the GDAS’ Project of Science and Technology Development (No. 2018GDASCX-0807 and 2018GDASCX-0116), and Science and technology program of Guangdong Province (No. 2017B030314137 and 2017A070701018).

Supporting Information

Rights and permissions

About this article

Cite this article

Wang, L., Yan, S., Zhang, L. et al. An Acid-/Base-Degradable Epoxy Resin Cured by 1,3,5-Triacroylamino-hexahydro-s-triazine Derivative. Macromol. Res. 29, 462–469 (2021). https://doi.org/10.1007/s13233-021-9060-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13233-021-9060-1