Abstract

Zinc oxide (ZnO) nanorods have been successfully synthesized by modified Pechini process. The as-synthesized ZnO nanorods were characterized by X-ray diffraction, scanning electron microscope, Raman spectrum, ultraviolet–visible (UV–vis) spectrum. X-ray diffraction result shows that the ZnO nanorods are oriented in wurtzite phase. Raman spectroscopy measurements revealed the presence of E2 (high) mode at 437 cm−1 indicating the high crystallinity of the as-synthesized ZnO nanorods. The optical property of the ZnO nanorods were studied from their UV–vis spectroscopy analysis which exhibits the absorbance at 373 nm corresponds to the Zn–O absorption. A mechanism for modified Pechini process for the synthesis of ZnO nanorods using citric acid–ethylene glycol precursor has also been proposed.

Similar content being viewed by others

Introduction

Zinc oxide (ZnO), a wide band-gap semiconductor with large exciton binding energy (about 60 meV) is one of the most promising semiconductor materials for its applications in various fields such as piezo electronic nano generators (Gao and Wang 2005), transparent electrodes (Battaglia et al. 2011), acoustic wave devices, UV detector (Chai et al. 2009), gas sensors (Yi et al. 2011), optoelectronic devices (Djurisi et al. 2010), photocatalytic activity (Mohan and Kim 2011), antibacterial and anticancer agent (Premanathan et al. 2011), etc. The size, shape, structure and morphology of nanostructured materials are well known to determine their physiochemical properties (Yi et al. 2008). The synthesis of low-dimensional nanostructures such as nanowires, nanorods, nanotubes, nano needles had achieved a lot of attention among the researchers due to their promising applications in nano-scaled optoelectronic devices (Guo et al. 2002; Pan et al. 2001; Zhang et al. 2002). Several methods like chemical vapor deposition (Hana et al. 2010), spray pyrolysis (Krunks et al. 2010), vapor-phase transport (Mohan et al. 2011), and hydrothermal method (Pei et al. 2010) have been employed to synthesize 1D ZnO nanostructures.

The conventional methods to synthesize 1D ZnO nanostructures are the vapor-phase transport processes with the aid of metal catalysts, thermal evaporation, and template-assisted growth. In addition, some chemical methods are also available for synthesizing ZnO nanorods viz., microwave irradiation method (Bhat 2008), modified micro emulsion method (Guo et al. 2002, etc. However, the 1D nanostructure prepared by these methods have trace amount of unwanted impurities (Bhat 2008). Thus, it is significant that preparation of 1D ZnO nanostructures without using any metal catalysts or templates through chemical routes provides promising method for the large-scale application. And also the other demerits of those methods stated above involve complex procedures, sophisticated equipment and rigorous experimental conditions. In these aspects, the development of low cost and new synthetic routes to ZnO nanorods or nanowires is of potential importance. In this paper, we are reporting the synthesis of ZnO nanorods using modified Pechini process.

Materials and methods

Materials

Zinc nitrate hexahydrate (Zn(NO3)2·6H2O), citric acid and ethylene glycol were purchased from Merck chemicals, India. Nitric acid was obtained from SD fine chemicals. Nitric acid was distilled in quartz apparatus before its use. All materials used in this study were of research grade.

Experimental procedure

ZnO nanorods were synthesized using the modified Pechini process using Zn(NO3)2·6H2O as the starting precursor. In brief, citric acid (2.58 g) dissolved in 2.7 mL of ethylene glycol was mixed with zinc nitrate solution (3.6558 g dissolved in 10 ml of HNO3) and vigorously stirred for 30 min to obtain a clear solution. Then, the solution was allowed to heating around 90°C with constant stirring for 2 h resulting in the formation of gel without any precipitation. The formed gel was further heated up to 150°C in order to get a dried gel. During this process, the product expanded three or four times the original volume resulting in bread like voluminous material. The resulting powder was allowed to calcine at 500°C in a vertical tube furnace for 2 h under flowing air. Finally, white-colored ZnO nanorods were obtained and stored in vacuum.

Characterization techniques

Phase purity and grain size were determined by X-ray diffraction (XRD) analysis recorded on a Siefert X-ray diffractometer (Richard Seifert and Co, Ahrensburg, Germany) using CuKα radiation (λ = 1.54016 Å) at 60 keV over the range of 2θ = 20–80°. Scanning electron microscopy (SEM) observations were conducted on FE-SEM (JSM-6700F, JEOL Ltd., Japan). The Raman scattering spectroscopy studies have been carried out by using a He–Ne laser with a 633 nm excitation wavelength (Jobin–Yvon Model HR800UV, Japan). The laser was focused using (100×) magnification objective lens, the signal was collected (10 s) in a backscattering geometry and guided to Peltier-cooled charge-coupled device (CCD) detector. The scan range was carried out in the wave number region 120–700 cm−1. Ultraviolet–visible (UV–vis) spectra of ZnO nanorods were recorded on a Perkin-Elmer 110 UV-Lambda 25 spectrophotometer (Perkin-Elmer, Norwalk, Connecticut).

Results and discussion

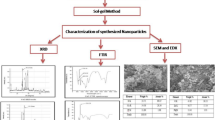

In our study, we used the modified Pechini process to synthesize ZnO nanorods using zinc nitrate as the starting precursor. This method involves the preparation of a gel from a solution of metal nitrates (oxidant), an organic additive (citric acid fuel) and ethylene glycol followed by the combustion of gel (Galceran et al. 2007). During the reaction, the metal–citrate mixture combines together and forms a complex with ethylene glycol. At this stage, the metal ions are distributed uniformly in the polymeric network which inhibits their segregation and precipitation. The rod-like structures is facilitated by ethylene glycol since it acts as a capping agent. This metal–citrate–polymer complex undergoes polymerization upon heating at 150°C. When the polymeric precursors are heated in air, they undergo combustion by liberating large amount of heat and produce the ZnO nanostructures. The surface morphology of the ZnO nanorods synthesized by modified Pechini process was analyzed using the SEM as shown in Fig. 1. It clearly shows the ZnO nanorods with breadth 300 nm and length 3 μm respectively.

The XRD pattern of ZnO nanorods prepared in using modified Pechini process was shown in Fig. 2. It clearly revealed that the ZnO nanorods were crystalline in nature, the diffraction peaks matched very well with the hexagonal wurtzite phase. Since the XRD do not have any additional peaks apart from the peaks characteristic for ZnO, suggesting that the formed product is being high-quality ZnO nanorods. The diffraction pattern and inter planar spacing are closely matched those in the standard diffraction pattern of ZnO (Wang et al. 2007) and International Centre for Diffraction Data, Joint Committee on Powder Diffraction Standards 36-1451. The peaks at 2θ = 31.77, 34.42, 36.25, 47.54, 56.56, 62.85, 66.32, 67.95, 69.10, and 72.79° were assigned to the (100), (002), (101), (102), (110), (103), (200), (112), (201), and (004) reflection planes of hexagonal wurtzite ZnO, respectively (Wu and Xue 2011).

Vibrational characteristics of the ZnO nanorods were employed from Raman spectroscopy. It is one of the versatile, non-destructive and widely used methods to study the structural properties of nano materials (Gouadec and Colomban 2007). The Raman spectrum of the ZnO nanorods measured using 633 nm excitation wavelength is shown in Fig. 3. The measured Raman spectrum was compared with the fundamental Raman active phonon modes for ZnO crystal reported previously (Damen et al. 1966). It can be concluded that the peak at 437 cm−1 corresponds to E2 (high), 374 cm−1 corresponds to A1 (TO) modes. The peak observed at ~331 cm−1 was attributed to multi-phonon scattering process (Music et al. 2005). The Raman spectrum shows that the highest intensity and narrow-line width were present in the E2 mode indicating that the nanorods were made of hexagonal wurtzite ZnO with good crystallinity.

The optical properties of the ZnO nanorods were studied using the UV–vis spectroscopy. The UV–vis spectrum of ZnO is represented in Fig. 4. It shows a sharp absorption band at 373 nm which corresponds to the absorbance of ZnO (Wu et al. 2006). The absorption spectra reveal that the ZnO nano rod has low-absorbance in the visible region which is characteristic of ZnO. The optical band gap energy of the ZnO was calculated by using the following equation:

where “α” is the absorption coefficient, “A” is a constant, “Eg” is the band gap and “n” is equal to 1/2 for a direct transition (Goldenblum et al. 2006). The band gap was estimated from a plot of (αhν)2 versus photon energy (hν). The intercept of the tangent to the plot gave a good approximation to the band gap energy for this direct band gap material. From Fig. 5, the band gap of the ZnO nanorods were evaluated and found equals to 3.56 eV which is slightly higher than the band gap of ZnO. The observed increase in band gap of the synthesized ZnO nanorods were more likely attributed to the contribution of quantum size effects. Moreover, it can be said that the synthesized ZnO nanorods are more suitable for optoelectronic applications due to the fact that the recombination processes are decreased in semiconductors with wide band gap.

Conclusion

A simple and low-cost route for obtaining the ZnO nanorods using the modified Pechini process has been reported. The possible mechanism of the growth of 1D structure is proposed. The XRD studies and Raman spectroscopic investigation revealed that the nanorods possess high crystallinity. A sharp absorption at 373 nm was observed in the UV–vis spectrum of ZnO nanorods and the optical band gap calculated using Tauc model is found as 3.56 eV. The band gap widening in the as-synthesized ZnO nanorods is most probably attributed to the contribution of quantum size effects in the 1D nanostructure. Our experimental results show that the ZnO nanorods might possess promising applications in the future optoelectronic device applications.

References

Battaglia C, Escarre J, Söderström K, Charrière M, Despeisse M, Haug FJ, Ballif C (2011) Nanomoulding of transparent zinc oxide electrodes for efficient light trapping in solar cells. Nat Photonics 5:535–538

Bhat DK (2008) Facile synthesis of ZnO nanorods by microwave irradiation of zinc–hydrazine hydrate complex. Nanoscale Res Lett 3:31–35

Chai G, Lupan O, Chow L, Heinrich H (2009) Crossed zinc oxide nanorods for ultraviolet radiation detection. Sens Actuators A 150:184–187

Damen TC, Porto SPS, Tell B (1966) Raman effect in zinc oxide. Phys Rev 142:570–574

Djurisi AB, Ng AMC, Chen XY (2010) ZnO nanostructures for optoelectronics: material properties and device applications. Prog Quantum Electron 34:191–259

Galceran M, Pujol MC, Aguilo M, Diaz F (2007) Sol-gel modified Pechini method for obtaining nanocrystalline KRE(WO4)2 (RE = Gd and Yb). J Sol-Gel Sci Tech 42:79–88

Gao PX, Wang ZL (2005) Nanoarchitectures of semiconducting and piezoelectric zinc oxide. J Appl Phys 97:044304

Goldenblum A, Belumarian A, Teodorescu V (2006) Optical properties of ZnO nanocrystallites embedded in a gold-oxide matrix. J Optoelectron Adv Mater 8:2129–2132

Gouadec G, Colomban P (2007) Raman Spectroscopy of nanomaterials: how spectra relate to disorder, particle size and mechanical properties. Prog Cryst Growth Charact Mater 3:1–56

Guo L, Ji YL, Xu HB, Simon P, Wu ZY (2002) Regularly shaped, single-crystalline ZnO nanorods with wurtzite structure. J Am Chem Soc 124:14864

Hana N, Hu P, Zuo A, Zhang D, Tian Y, Chen Y (2010) Photoluminescence investigation on the gas sensing property of ZnO nanorods prepared by plasma-enhanced CVD method. Sens Actuators B 145:114–119

Krunks M, Karber E, Katerski A, Otto K, Acik IO, Dedova T, Mere A (2010) Extremely thin absorber layer solar cells on zinc oxide nanorods by chemical spray. Sol Energy Mater Sol Cells 94:1191–1195

Mohan R, Kim S-J (2011) Current biased resistive switching in ZnO whiskers. Jpn J Appl Phys 50:04DJ01

Mohan R, Krishnamoorthy K, Kim S-J (2011) Enhanced photocatalytic activity of Cu-doped ZnO nanorods. Solid State Commun 152:375–380

Music S, Dragevic D, Popovic S, Ivanda M (2005) Precipitation of ZnO particles and their properties. Mater Lett 59:2388–2393

Pan ZW, Dai ZR, Wang ZL (2001) Nanobelts of semiconducting oxides. Science 291:1947

Pei LZ, Zhao HS, Tan W, Yu HY, Chen YW, Fan CG, Zhang QF (2010) Hydrothermal oxidization preparation of ZnO nanorods on zinc substrate. Physica E 42:1333–1337

Premanathan M, Karthikeyan K, Jeyasubramanian K, Manivannan G (2011) Selective toxicity of ZnO nanoparticles toward Gram positive bacteria and cancer cells by apoptosis through lipid peroxidation. Nanomedicine NBM 7:184–192

Wang M, Na EK, Kim JS, Kim EJ, Hahn SH, Park C, Koo KK (2007) Photoluminescence of ZnO nanoparticles prepared by a low-temperature colloidal chemistry method. Mater Lett 61:4094–4096

Wu J, Xue D (2011) Progress of science and technology of ZnO as advanced material. Sci Adv Mater 3:127–149

Wu L, Wu Y, Pan X, Kong F (2006) Synthesis of ZnO nanorod and the annealing effect on its photoluminescence property. Opt Mater 28:418–422

Yi R, Zhang N, Zhou H, Shi R, Qiu G, Liu X (2008) Selective synthesis and characterization of flower-like ZnO microstructures via a facile hydrothermal route. Mater Sci Eng, B 153:25–30

Yi J, Lee JM, Park W (2011) Vertically aligned ZnO nanorods and graphene hybrid architectures for high-sensitive flexible gas sensors. Sens Actuators B 155:264–269

Zhang J, Sun L, Liao C, Yan C (2002) A simple route towards tubular ZnO. Chem Commun 3:262–263

Acknowledgments

The authors thank the Principal and management of Mepco Schlenk Engineering College, Sivakasi for their constant support and encouragement.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Devaraj, R., Karthikeyan, K. & Jeyasubramanian, K. Synthesis and properties of ZnO nanorods by modified Pechini process. Appl Nanosci 3, 37–40 (2013). https://doi.org/10.1007/s13204-012-0072-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-012-0072-1