Abstract

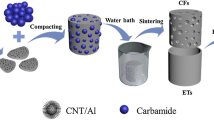

In this study, aluminum foams reinforced with multi-walled carbon nanotubes (0%, 0.5%, 1%, and 2% by weight) were produced by powder metallurgy method using different proportions of spherical urea (15%, 30%, and 50% by weight) as space holder. It analyzes the pore morphology and pore distribution of the produced composite foams and examines their mechanical properties under qua-static compressive loading. The results show that the effect of multi-walled carbon nanotubes existing in the cell wall on pore morphology and pore distribution was insignificant. The highest hardness value (65 HV) was determined in the foam samples containing 2% multi-walled carbon nanotube produced with 15% urea. Composite aluminum foam samples with 30–69% porosity and 0.84–1.90 g cm−3 density were successfully produced. The compression properties of the samples decreased with the decrease in the relative densities.

Similar content being viewed by others

References

Muchhala D, Yadav B N, Kumar R, Mondal D P, Venkat A C,Compos Part B 176 (2019) 107304.

Wang J, Yang X, Zhang M, Li J, Shi C, Zhao N, Zou T, Mater Lett 161 (2015) 763.

Yang K, Yang X, Liu E, Shi C, Ma L, He C, Li Q, Li J, Zhao N, Mater Sci Eng A 690 (2017) 294

Yang K, Yang X, Liu E, Shi C, Ma L, He C, Li Q, Li J, Zhao N, Mater Sci Eng A 729 (2018) 487

Rajak D K, Kumaraswamidhas L A, Das S, Ciência & Tecnologia dos Materiais 29 (2017) 14.

Mu Y, Yao G, Liang L, Luo H, Zu G, Scr Mater 63 (2010) 629.

Kadkhodapour J, Raeisi S, Comput Mater Sci 83 (2014) 137.

Wang N, Maire E, Chen X, Adrien J, Li Y, Amani Y, Hu L, Cheng Y, Mater Charact 147 (2019) 11.

An Y, Yang S, Wu H, Zhao E, Wang Z, Mater Des 134 (2017) 44.

Badkul A, Saxena S, Mondal D P, Compos Struct 246, (2020) 112419.

Duarte I, Ferreira J M, Materials 9 (2016) 79.

Yang X, Hu Q, Li W, Song H, Zou T, Zong R, Sha J, He C, Zhao N, Fatigue Fract Eng Mater Struct 43 (2020) 744.

Daoud A, J Alloys Compd 487 (2009) 618.

Smorygo O, Mikutski V, Marukovich A, Sadykov V, Bespalko Y, Stefan A, Pelin C E, Compos Struct 202 (2018) 917.

Fiedler T, Al-Sahlani K, Linul P A, Linul E, J Alloys Compd 813 (2020) 152181.

Zhang Q, Lin Y, Chi H, Chang J, Wu G, Compos Struct 183 (2018) 499.

Kumar N R, Rao N R, Gokhale A A, Mater Sci Eng A 598 (2014) 343.

Xu J, Yang X, He C, Yang K, Li W, Sha J, Zhao N, J Mater Sci 55 (2020) 7910.

Carvalho O, Buciumeanu M, Madeira S, Miranda G, Silva F S, Compos Part B 93 (2016) 229.

Han L, Li K, Sun J, Song Q, Wang Y, Mater Sci Eng A 735 (2018) 10.

Aldoshan A, Khanna S, Mater Sci Eng A 689 (2017) 17.

Yang K, Yang X, He C, Liu E, Shi C, Ma L, Li Q, Li J, Zhao N, Mater Lett 209 (2017) 68.

Yang X, Hu Q, Du J, Song H, Zou T, Sha J, He C, Zhao N, Int J Fatigue 121 (2019) 272.

Duarte I, Ventura E, Olhero S, Ferreira J M, Carbon 95 (2015) 589.

Zhang Z, Ding J, Xia X, Sun X, Song K, Zhao W, Liao B, Mater Des 88 (2015) 359.

Ogawa F, Yamamoto S, Masuda C, Mater Sci Eng A 711 (2018) 460.

Huang H, Fan G, Tan Z, Xiong D B, Guo Q, Guo C, Li Z, Zhang D, Mater Sci Eng A 699 (2017) 55.

Duarte I, Ventura E, Olhero S, Ferreira J M, Mater Lett 160 (2015) 162.

Duarte I, Ventura E, Olhero S, Ferreira J M F, Ciência & Tecnologia dos Materiais 28, (2016) 5.

Yadav B N, Muchhala D, Sriram S, Mondal D P, J Alloys Compd 832 (2020) 154860.

Hassani A, Habibolahzadeh A, Bafti H, Mater Des 40, (2012) 510.

Dahil L, Katirci R, Sümbül H I, T Indian I Metals, 73 (2020) 2739.

An J, Chen C, Zhang M, Opt Laser Technol 141 (2021) 107097.

Zhang M, Chen C, Huang Y, Mater Sci Tech 34 (2018) 968.

Zhao N Q, Jiang B, Du X W, Li J J, Shi C S, Zhao W X, Mater Lett 60, (2006) 1665.

Jiang B, Zhao N Q, Shi C S, Li J J, Scr Mater. 53 (2005) 781.

Bakan H I, Scr Mater 55 (2006) 203.

Liu Z Y, Zhao K, Xiao B L, Wang W G, Ma Z Y, Mater Des 97 (2016) 424.

Zhang Z, Feng H, Xu T, Xin W, Ding J, Liu N, Wang Z, Wang Y, Xia X, Liu Y, Compos Struct 283 (2022) 115090.

Abhash A, Singh P, Kumar R, Pandey S, Sathaiah S, Shafeeq M M, Mondal D P, Mater Sci Eng C 109 (2020) 110600.

Markaki A E, Clyne T W, Acta Mater 49 (2001) 1677.

Gui M C, Wang D B, Wu J J, Yuan G J, Li C G, Mater Sci Eng A 286 (2000) 282.

Daoud A, J Alloys Compd 486 (2009) 597.

Zhang B, Lin Y, Li S, Zhai D, Wu G, Compos Part B 98 (2016) 288.

Jiang B, Wang Z, Zhao N, Scr Mater 56 (2007) 169.

Ashby M F, Evans T, Fleck N A, Hutchinson J, Wadley H, Gibson L, Metal foams: a design guide, Elsevier (2000).

Banhart J, Prog Mater Sci 46 (2001) 559.

Gibson L J, Annu Rev Mater Sci 30 (2000) 191.

Bafti H, Habibolahzadeh A, Mater Des 52 (2013) 404.

Chen B, Li S, Imai H, Jia L, Umeda J, Takahashi M, Kondoh K, Compos Sci Technol 113 (2015) 1.

Boesl B, Lahiri D, Behdad S, Agarwal A, Carbon 69 (2014) 79.

Yang D, Hu Z, Chen W, Lu J, Chen J, Wang H, Wang L, Jiang J, Ma A, J Manuf Processes 22 (2016) 290.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Abo sbia, A.E.S., Uzun, A. Production of MWCNT-Reinforced Aluminum Foams Via Powder Space-Holder Technique and Investigation of their Mechanical Properties. Trans Indian Inst Met 75, 2241–2253 (2022). https://doi.org/10.1007/s12666-022-02589-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02589-3