Abstract

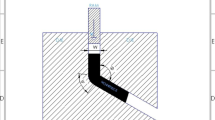

In the present research, the effect of inner corner radius of ECAP die on the material flow characteristic and the strain distribution inside sample were analyzed using 2D plain strain finite element simulation. Results showed that increase in inner corner radius results in the formation of smaller corner gap and narrow deformation zone. Consequently, the amount of plastic strain in regions at the bottom side of sample is increased. It is also concluded that the amount of damage factor in the upper regions of sample is higher than bottom regions and therefore cracks may initiate from these regions. In addition, the pressing force was raised by increasing inner corner radius.

Similar content being viewed by others

References

Yada H, Matsumura Y, and Nakajima K, United State Patent No. 4466842, August 21 (1984).

Fan Z, Mater Sci Eng A 191 (1995) 73. https://doi.org/10.1016/0921-5093(94)09621-3.

Langdon T G, J Mater Sci 42 (2007) 3388. https://doi.org/10.1007/s10853-006-1475-8.

Valiev R Z, Islamgoliev R K, and Alexandrov I V, Prog Mater Sci 45 (2000) 103. https://doi.org/10.1016/S0079-6425(99)00007-9.

Valiev R Z, J Mater Sci 42 (2007) 1483. https://doi.org/10.1007/s10853-006-1281-3.

Huang X, J Mater Sci 42 (2007) 1577. https://doi.org/10.1007/s10853-006-0988-5.

Furukawa M, Horita Z, Nemoto M, and Langdon T G, J Mater Sci 36 (2001) 2835. https://doi.org/10.1023/A:1017932417043.

Valiev R Z, and Langdon T G, Prog Mater Sci 51 (2006) 881. https://doi.org/10.1016/j.pmatsci.2006.02.003.

Berbon P B, Furukawa M, Horita Z, Nemoto M, and Langdon T G, Metall Mater Trans A 30 (1999) 1989. https://doi.org/10.1007/s11661-999-0009-9.

Iwahashi Y, Wang J, Horita Z, Nemoto M, and Langdon T G, Scripta Mater 35 (1996) 143. https://doi.org/10.1016/1359-6462(96)00107-8.

Nakashima K, Horita Z, Nemoto M, and Langdon T G, Acta Mater 46 (1998) 1589. https://doi.org/10.1016/S1359-6454(97)00355-8.

Prangnell P B, Harris C, and Roberts S M, Scr Mater 37 (1997) 983. https://doi.org/10.1016/S1359-6462(97)00192-9.

Cerri E, Marco P P, and Leo P, J Mater Process Technol 209 (2009) 1550. https://doi.org/10.1016/j.jmatprotec.2008.04.013.

Figueiredo R B, Cetlin P R, and Langdon T G, Mater Sci Eng A 518 (2009) 124. https://doi.org/10.1016/j.msea.2009.04.007.

Figueiredo R B, Cetlin P R, and Langdon T G, Acta Mater 55 (2007) 4769. https://doi.org/10.1016/j.actamat.2007.04.043.

Yoon S C, and Kim H S, Mater Sci Eng A 490 (2008) 438. https://doi.org/10.1016/j.msea.2008.01.066.

Kim H S, Seo M H, and Hong S I, Mater Sci Eng A 291 (2000) 86. https://doi.org/10.1016/S0921-5093(00)00970-9.

Basavaraj V P, Chakkingal U, and Kumar T S J Mater Process Technol 209 (2009) 89. https://doi.org/10.1016/j.jmatprotec.2008.01.031.

Kang F, Wang J T, and Peng Y, Mater Sci Eng A 487 (2008) 68. https://doi.org/10.1016/j.msea.2007.09.063.

Lin J, Liu Y, and Din T A, Int J Damage Mech 14 (2005) 299. https://doi.org/10.1177/1056789505050357.

Ghazani M S, and Eghbali B, Comput Mater Sci 74 (2013) 124. https://doi.org/10.1016/j.commatsci.2013.02.006.

Figueirdo R B, Cetlin P R, and Langdon T G, Metall Mater Trans A 41 (2010) 778. https://doi.org/10.1007/s11661-009-0100-2.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Ghazani, M.S., Moslemi, S. The Effect of Inner Corner Radius of ECAP Die on Strain Distribution and Damage Accumulation in Deformed Sample. Trans Indian Inst Met 71, 971–976 (2018). https://doi.org/10.1007/s12666-017-1230-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-017-1230-7