Abstract

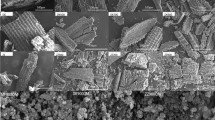

Hemp hurd, which is the major byproduct produced during the extraction of its bast fiber was effectively converted into carbonaceous materials at 400, 500, 700, and 900 °C. The influence of pyrolysis temperature on the physiochemical properties of carbonaceous materials such as elemental composition, ash content, chemical functionality, graphitic content, thermal stability, surface morphology, and particle size, were investigated. The obtained features were then correlated with the electrical conductivity of the produced biocarbon. It was determined that the functional groups present in the biocarbon materials synthesised at lower temperatures (400 and 500 °C) almost disappeared for the biocarbon pyrolyzed at higher temperatures (700 and 900 °C). Raman analysis reveals that the ID/IG ratio of the biocarbon decreases with increased carbonization temperature. This indicates the formation of graphitized carbon clusters at higher temperatures and influences the superior electrical conductivity. In addition, the biocarbon carbonized at 900 °C exhibited the highest thermal stability, carbon content, and graphitic content when compared with their respective low-temperature counterparts. Increasing graphitic nature of the biocarbon materials during the high temperature carbonization along with the decrement of oxygen containing surface functional groups resulted in increased electron transport, which resulted in the biocarbon carbonized at 900 °C having the highest electrical conductivity of 15 S/m.

Similar content being viewed by others

Explore related subjects

Discover the latest articles and news from researchers in related subjects, suggested using machine learning.Data Availability

The datasets used and/or analyzed during the current study will be available from the corresponding author on reasonable request.

References

Mohanty, A.K., Vivekanandhan, S., Das, O., Romero Millán, L.M., Klinghoffer, N.B., Nzihou, A., Misra, M.: Biocarbon materials. Nat. Rev. Methods Primers. 4, 19 (2024)

Liu, W.J., Jiang, H., Yu, H.Q.: Development of biochar-based functional materials: Toward a sustainable platform carbon material. Chem. Rev. 115, 12251–12285 (2015)

He, M., Xu, Z., Hou, D., Gao, B., Cao, X., Ok, Y.S., Rinklebe, J., Bolan, N.S., Tsang, D.C.: Waste-derived biochar for water pollution control and sustainable development. Nat. Rev. Earth Environ. 3, 444–460 (2022)

Vivekanandhan, S.: Biochar supercapacitors: recent developments in the materials and methods in Green and Sustainable Advanced Materials: Applications 2, 223–249 (2018)

Yasim-Anuar, T.A.T., Yee-Foong, L.N., Lawal, A.A., Farid, M.A.A., Yusuf, M.Z.M., Hassan, M.A., Ariffin, H.: Emerging application of biochar as a renewable and superior filler in polymer composites. RSC Adv. 12, 13938–13949 (2022)

Das, S.K., Ghosh, G.K., Avasthe, R.: Biochar application for environmental management and toxic pollutant remediation. Biomass Conv Bioref. 13, 555–566 (2023)

Lee, J., Kim, K.H., Kwon, E.E.: Biochar as a catalyst. Renew. Sust Energ. Rev. 77, 70–79 (2017)

Charlier, J.C., Issi, J.P.: Electrical conductivity of novel forms of carbon. J. Phys. Chem. Solids. 57, 957–965 (1996)

Celzard, A., Marêché, J., Payot, F., Furdin, G.: Electrical conductivity of carbonaceous powders. Carbon. 40, 2801–2815 (2002)

Chung, D.D.L.: Electrical applications of carbon materials. J. Mater. Sci. 39, 2645–2661 (2004)

Gabhi, R., Basile, L., Kirk, D.W., Giorcelli, M., Tagliaferro, A., Jia, C.Q.: Electrical conductivity of wood biochar monoliths and its dependence on pyrolysis temperature. Biochar. 2, 369–378 (2020)

Tripathi, N., Uribe, A.R., Weldekidan, H., Misra, M., Mohanty, A.K.: Upcycling of waste jute biomass to advanced biocarbon materials: The effect of pyrolysis temperature on their physicochemical and electrical properties. Mater. Adv. 3, 9071–9082 (2022)

de Paiva, M.V., Bettini, J., Colombari, F.M., Fazzio, A., Strauss, M.: Unveiling electrical anisotropy of hierarchical pyrolytic biocarbons from wood cellulose. J. Mater. Sci. 57, 21980–21995 (2022)

Weldekidan, H., Vivekanandhan, S., Tripathi, N., Mohanty, A., Misra, M.: Highly conductive biocarbon nanostructures from burlap waste as sustainable additives for supercapacitor electrodes. Mater. Adv. 5, 1240–1250 (2024)

Demir, M., Kahveci, Z., Aksoy, B., Palapati, N.K., Subramanian, A., Cullinan, H.T., El-Kaderi, H.M., Harris, C.T., Gupta, R.B.: Graphitic biocarbon from metal-catalyzed hydrothermal carbonization of lignin. Ind. Eng. Chem. Res. 54, 10731–10739 (2015)

Bokhari, S.M., Chi, K., Catchmark, J.M.: Structural and physico-chemical characterization of industrial hemp hurd: Impacts of chemical pretreatments and mechanical refining. Ind. Crop Prod. 171, 113818 (2021)

Barker, B.: Industrial hemp harvest and storage: best management practices. Ministry of Agriculture and Irrigation, Government of Alber ta, Alberta, Canada, (2016). https://www.canada.ca/en/health-canada/services/drugs-medication/cannabis/producing-selling-hemp/about-hemp-canada-hemp-industry/statistics-reports-fact-sheets-hemp.html#s2022

Arango, S., Greco, R., Guzzo, N., Raffrenato, E., Montanari, M., Bailoni, L.: Physical characterization of ten hemp varieties to Use as Animal Bedding Material. Animals. 13, 284 (2023)

Battegazzore, D., Noori, A., Frache, A.: Hemp Hurd and alfalfa as particle filler to improve the thermo-mechanical and fire retardant properties of poly (3‐hydroxybutyrate‐co‐3‐hydroxyhexanoate). Polym. Compos. 40, 3429–3437 (2019)

Viscusi, G., Lamberti, E., Gorrasi, G.: Design of a hybrid bio-adsorbent based on Sodium Alginate/Halloysite/Hemp Hurd for methylene blue dye removal: Kinetic studies and mathematical modeling. Colloid Surf. A. 633, 127925 (2022)

Khan, B.A., Wang, J., Warner, P., Wang, H.: Antibacterial properties of hemp hurd powder against E. Coli. J. Appl. Polym. Sci. 132, (2015)

Barbieri, V., Gualtieri, M.L., Manfredini, T., Siligardi, C.: Lightweight concretes based on wheat husk and hemp hurd as bio-aggregates and modified magnesium oxysulfate binder: Microstructure and technological performances. Constr. Build. Mater. 284, 122751 (2021)

Puglia, M., Morselli, N., Lumi, M., Santunione, G., Pedrazzi, S., Allesina, G.: Assessment of hemp hurd-derived biochar produced through different thermochemical processes and evaluation of its potential use as soil amendment. Heliyon 9, (2023)

Liu, S., Ge, L., Gao, S., Zhuang, L., Zhu, Z., Wang, H.: Activated carbon derived from bio-waste hemp hurd and retted hemp hurd for CO2 adsorption. Comp. Commun. 5, 27–30 (2017)

Brandão, A.T., State, S., Costa, R., Potorac, P., Vázquez, J.A., Valcarcel, J., Silva, A.F., Anicai, L., Enachescu, M., Pereira, C.M.: Renewable carbon materials as electrodes for high-performance supercapacitors: From marine biowaste to high specific surface area porous biocarbons. ACS Omega. 8, 18782–18798 (2023)

Maceda, A., Soto-Hernández, M., Peña-Valdivia, C.B., Trejo, C., Terrazas, T.: Characterization of lignocellulose of Opuntia (Cactaceae) species using FTIR spectroscopy: Possible candidates for renewable raw material. Biomass Conv Bioref. 12, 5165–5174 (2022)

Yang, J., Zhao, Z., Hu, Y., Abbey, L., Cesarino, I., Goonetilleke, A., He, Q.: Exploring the properties and potential uses of biocarbon from spent coffee grounds: A comparative look at dry and wet processing methods. Processes. 11, 2099 (2023)

Sumangala Devi, N., Vivekanandhan, S.: Effect of carbonization temperatures on the synthesis of biocarbon from Borassus flabellifer fruit fiber for capacitive energy storage. Appl. Res. 3(5), e202400005 (2024)

Wang, B., Shi, T., Zhang, Y., Chen, C., Li, Q., Fan, Y.: Lignin-based highly sensitive flexible pressure sensor for wearable electronics. J. Mater. Chem. C. 6, 6423–6428 (2018)

Apaydın Varol, E., Mutlu, Ü.: TGA-FTIR analysis of biomass samples based on the thermal decomposition behavior of hemicellulose, cellulose, and lignin. Energies. 16, 3674 (2023)

Mishra, R.K., Misra, M., Mohanty, A.K.: Value-added biocarbon production through slow pyrolysis of mixed bio-oil wastes: Studies on their physicochemical characteristics and structure–property–processing co-relation. Biomass Conv Bioref. 14, 7887–7901 (2024)

Dominguez, A., Menéndez, J., Fernandez, Y., Pis, J., Nabais, J.V., Carrott, P., Carrott, M.R.: Conventional and microwave induced pyrolysis of coffee hulls for the production of a hydrogen rich fuel gas. J. Anal. Appl. Pyrol. 79, 128–135 (2007)

Quosai, P., Anstey, A., Mohanty, A.K., Misra, M.: Characterization of biocarbon generated by high-and low-temperature pyrolysis of soy hulls and coffee chaff: For polymer composite applications. R Soc. Open. Sci. 5, 171970 (2018)

Agweh, K., Snowdon, M.R., Mishra, R.K., Chen, G., Vivekanandhan, S., Mohanty, A.K., Misra, M.: Production and characterization of waste nutshells derived biocarbon through slow pyrolysis: An investigation on the effects of pyrolysis temperature. Biomass Conv Bioref. 34, 28619–28633 (2023)

Wang, L., Khalil, R.A., Bakken, J., Skreiberg, Ø.: Production and characterization of biocarbon from woody biomasses produced at 1000°C. Fuel. 370, 131667 (2024)

Sahoo, S.S., Vijay, V.K., Chandra, R., Kumar, H.: Production and characterization of biochar produced from slow pyrolysis of pigeon pea stalk and bamboo. Clean. Eng. Technol. 3, 100101 (2021)

Giannakopoulos, S., Vakros, J., Frontistis, Z., Manariotis, I.D., Venieri, D., Poulopoulos, S.G., Mantzavinos, D.: Biochar from lemon stalks: A highly active and selective carbocatalyst for the oxidation of sulfamethoxazole with persulfate. Catalysts. 13, 233 (2023)

Keown, D.M., Li, X., Hayashi, J.I., Li, C.Z.: Evolution of biomass char structure during oxidation in O2 as revealed with FT-Raman spectroscopy. Fuel Process. Technol. 89, 1429–1435 (2008)

Debevc, S., Weldekidan, H., Snowdon, M.R., Vivekanandhan, S., Wood, D.F., Misra, M., Mohanty, A.K.: Valorization of almond shell biomass to biocarbon materials: Influence of pyrolysis temperature on their physicochemical properties and electrical conductivity. Carbon Trends. 9, 100214 (2022)

Sills, D.L., Gossett, J.M.: Using FTIR to predict saccharification from enzymatic hydrolysis of alkali-pretreated biomasses. Biotechnol. Bioeng. 109, 353–362 (2012)

Dahal, R.K., Acharya, B., Dutta, A.: The Interaction Effect of the design parameters on the Water absorption of the Hemp-Reinforced Biocarbon-filled Bio-epoxy composites. Int. J. Mol. Sci. 24, 6093 (2023)

Kang, S., Kim, B., Lee, S., Baek, J., Yoo, J.: Tailoring porosity of starch-derived biocarbon for enhanced supercapacitor performance. Mater. Technol. 39, 2338628 (2024)

Cançado, L., Takai, K., Enoki, T., Endo, M., Kim, Y., Mizusaki, H., Speziali, N., Jorio, A., Pimenta, M.: Measuring the degree of stacking order in graphite by Raman spectroscopy. Carbon. 46, 272–275 (2008)

Zhao, B., O’Connor, D., Zhang, J., Peng, T., Shen, Z., Tsang, D.C., Hou, D.: Effect of pyrolysis temperature, heating rate, and residence time on rapeseed stem derived biochar. J. Clean. Prod. 174, 977–987 (2018)

Watt, E., Abdelwahab, M.A., Mohanty, A.K., Misra, M.: Biocomposites from biobased polyamide 4, 10 and waste corn cob based biocarbon. Compos. Part. A-Appl S. 145, 106340 (2021)

Picard, M., Thakur, S., Misra, M., Mielewski, D.F., Mohanty, A.K.: Biocarbon from peanut hulls and their green composites with biobased poly (trimethylene terephthalate)(PTT). Sci. Rep. 10, 3310 (2020)

Majchrzak-Kucęba, I., Sołtysik, M.: The potential of biocarbon as CO2 adsorbent in VPSA unit. J. Therm. Anal. Calorim. 142, 267–273 (2020)

Kane, S., Ulrich, R., Harrington, A., Stadie, N.P., Ryan, C.: Physical and chemical mechanisms that influence the electrical conductivity of lignin-derived biochar. Carbon Trends. 5, 100088 (2021)

Funding

This study was financially supported by (i) the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA)/University of Guelph– Bioeconomy for Industrial Uses Research Program (Project Nos. 030699 and 100038), (ii) the Natural Sciences and Engineering Research Council of Canada (NSERC), Canada Research Chair (CRC) program (Project No. 460788), and (iii) the NSERC Discovery Grants (Project No. 401111); and (iii) Agriculture and Agri-Food Canada (AAFC) and Bioindustrial Innovation Canada (BIC) (Project No. 056369). This research has also benefited from the facility funding to the BDDC supported by FedDev Ontario; OMAFRA; Canada Foundation for Innovation (CFI); Federal Post- Secondary Institutions Strategic Investment Fund (SIF), Bank of Montreal (BMO) and University of Guelph’s Alumni.

Author information

Authors and Affiliations

Contributions

Hugh MacFarlane: Methodology, Investigation, Formal analysis, Writing– original draft. Singaravelu Vivekanandhan: Investigation, Validation, Formal analysis, Writing– original draft. Zavier Blackman: Methodology, Investigation, Writing– review & editing. Amar K. Mohanty: Conceptualization, Methodology, Investigation, Validation, Funding acquisition, Project administration, Supervision, Writing– review & editing. Arturo Rodriguez-Uribe: Methodology, Writing– review & editing. Neelima Tripathi: Methodology, Writing– review & editing. Mahendra Thimmanagari: Writing– review & editing. Manjusri Misra: Conceptualization, Methodology, Investigation, Validation, Resources, Visualization, Project administration, Funding acquisition, Supervision, Writing– review & editing.

Corresponding authors

Ethics declarations

Competing Interests

The authors declare that they have no known conflict of interest that could have appeared to influence the work reported in this work.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

MacFarlane, H., Vivekanandhan, S., Blackman, Z. et al. Hemp Hurd Derived Biocarbon Materials: Investigating the Effect of Pyrolysis Temperature on the Physicochemical Properties towards High Electrical Conductivity. Waste Biomass Valor (2025). https://doi.org/10.1007/s12649-025-02940-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12649-025-02940-x