Abstract

Purpose

to propose two enhancements for the European Union’s Circular Material Use rate (CMU): inclusion of Preparation for Reuse (PfR) flows and enhanced reproducibility across lower levels of analysis.

Methods

PfR flows are added to the material flow Sankey Diagram. The Local Circularity Rate (LCR) is based in the CMU and is broke down in three waste-related ratios: recovered-to-treated (RCV-to-TRT), treated-to-end-of-life and end-of-life-to-overall-material-use (EoL-to-OMU). LCR, CMU and CMU’, an alternate version of CMU, are computed and compared in the macro-level for EU27 member states and in the meso-level for Germany’s sixteen states. LCR is computed and broke down for regions in Belgium, The Netherlands and Greece. In the micro-level, LCR is computed for a network modelled around a Textile Sorting Centre (TSC) in Amsterdam.

Results

LCR showed closer average results to CMU in comparison to CMU’. Considering RCV-to-TRT and EoL-to-OMU, The Netherlands and Luxembourg are the best performing countries in the EU27. Eight countries performed worse than 0.4 in both ratios. In total, twelve German regions showed negative results, either for CMU or CMU’. Saxony-Anhalt is the most circular region in Germany, while Berlin is the less circular. The Amsterdam textiles’ network features an LCR of 12%, with the TSC contributing to 63% of all textiles recovered.

Conclusion

The revised circular Sankey Diagram comprehensively illustrates the circularity gap. LCR’s three ratios enhances in-depth analysis, allowing better prioritisation of public policies. Limitations remain in data availability and harmonisation across regional and national databases.

Graphic Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Statement of Novelty

A circularity metric that enables comparison between cities, regions and countries, accounts for Preparation for Reuse flows and allows in-depth analysis, is proposed.

Introduction

Worldwide, only 8.6% of all resources consumed were cycled back in 2020 [1]; the remaining fraction of 91.4% of resources not returning to the economy is called the Circularity Gap [2] (CG). At the forefront of the transition to a Circular Economy (CE), the European Union (EU) could cycle back only 13% of all material consumed [3] in 2020. Although 100% of circularity is not technically feasible [4], the EU is set to decrease its 87% CG through the European CE Action Plan [5]. The EU monitors resource circularity through the Circular Material Use Rate (CMU), the ratio between secondary materials (SM) and overall material used, OMU [6]. All material flowing through EU’s twenty-seven member states (EU27) is graphically represented in material flow Sankey Diagrams (SD), available at the Eurostat portal [7]. The SD and the CMU are part of the EU’s official CE Monitoring Framework (EUCEMF).

Three limitations can be observed with the EUCEMF: First, the SD and the CMU consider only recycled materials (\(RCV_R\)) as secondary materials. Preparation for Reuse (PfR), second most preferred recovery strategy in EU’s Waste Directive ladder [8], consisting of the activities of resell, repair, repurpose, refurbishing and remanufacturing, is currently not accounted for. Great potential to recover products through PfR have been identified [9,10,11], while an increase of the sustainability performance of supply chains shifting to PfR flows has been demonstrated [12]. Moreover, to the best of the authors’ knowledge, PfR flows have not been included in state-of-the-art multi-level resource circularity frameworks to this date.

Second, CMU’s reproducibility is limited to the high aggregate levels of countries and continents. Recovered material SM is defined subtracting imports of waste (\(IMP_W\)) from the sum of waste recovered with waste exported, \(RCV_R + EXP_W\). Such definition works well for highly aggregated regions; however, when waste imported is in the same order of magnitude than the sum of waste locally produced with waste exported, a negative value circularity might be found. This situation is quite common in smaller region; in fact, such distortions can be already observed in small countries like Luxembourg, which imports large amounts of metal residues [13]. Not even in the alternate version of CMU, CMU’ [6], where SM is defined adding imported waste and subtracting exported waste, or \(RCV_R + IMP_W - EXP_W\), the problem is overcome. CMU’ also brings another distortion: countries can improve their CMU importing waste for incineration. Hence, both propositions fail to capture circularity in the local level, where resource circularity is actually taking place. Last, data for imports and exports of waste require a laborious filtering process of a comprehensive database of exchanged goods, while CMU cannot be computed using figures from the SDs either, although their connection has been stressed [14].

This research aims to fill the gaps described above by redesigning the SD and the CMU using the CG approach. A new, Local Circularity Rate (LCR) is proposed, accounting for PfR flows allowing multi-level comparison and a breakdown analysis of resource circularity. In the micro-level, the Resource Circularity Network (RCNs) is modelled based on the generic framework of Reike et al. [15] around Urban Resource Centres (URCs) [16], organisations gathering local communities to enhance recovery through PfR. Mathematical expressions for resource circularity are defined for the macro-, meso- and micro-level of analysis, and the share of contribution of an URC for all material recovered is quantified. The propositions are demonstrated through cases of application in the three levels; resource circularity of countries, regions, cities and an RCN, respectively, are analysed.

Background

In Sect. 3.1, metrics and methods to monitor resource circularity are introduced, and material flows used for the calculations of CMU are described. Examples of downscaling techniques are presented, and circularity indexes in the micro-level are briefly discussed. A brief state-of-the-art of regional and multi-level frameworks is also provided. In Sect. 3.2 PfR and local agents responsible delivering these flows, the Urban Resource Centres, are introduced.

Monitoring Resource Circularity

With the adoption of CE as the new sustainable economic paradigm, resource circularity has been defined and quantified. A comprehensive list of indicators and metrics to measure CE, including resource circularity, can be found in Corona et al. [17]. Official metrics for resource circularity are currently based in Material Flow Analysis (MFA), modelled through sociometabolic approaches [18]. The remaining fraction of resources not circled, the CG, has been reported in the global level since 2018 [19]. Figure 1 depicts the CG and resources lifecycle phases of take, make, stock, waste, dispose and cycle. The CG is the lower empty half of the cycle, and can be bridged through four CE strategies: a) stop extracting natural resources, b) optimise resources that are available, c) stop wasting resources, and d) cycling more resources and better. One can observe the CG in different levels, from the micro-level of a municipality up to the global level. PfR activities are concerned with strategy d).

The CG. Four strategies to close the gap are indicated with exclamation signals: stop extracting and stop wasting (coloured red for being more critical), stock optimisation and closing material loops - through e.g. recovering, recycling, reimagining -, coloured blue for being less critical. Source: [2]

The CG of a country, \(NCG_c\), is determined with the expression \(NCG_c = 1 - CMU_c\). CMU is the Circular Material Use Rate, part of the EUCEMF, a set of metrics provided by Eurostat, EU’s official statistics institute, to standardise reporting of CE in the EU [20]. The CMU of the c-th country of EU27 can be computed using Eq. 1 [6], as the share of SM from OMU. SM is the sum of \(RCV_R\), waste recovered locally, with \(EXP_W\), waste exports, subtracting imports of waste, \(IMP_W\). DMC stands for Domestic Material Consumption [21], the “total amount of materials directly used by an economy” [22]. These figures are normally expressed in kilotonnes per year, while the CMU is reported bi-yearly.

Figures for DMC and \(RCV_R\) can be found on the Eurostat portal, under datasets ENV_AC_MFA and ENV_WASTRT, respectively. Figures for \(EXP_W\) and \(IMP_W\) can be retrieved from dataset DS-045409, through a laborious filtering process. All material flows imported, processed within the EU and exported for in 2018 can be observed in the material flow SD of Fig. 9. The same diagram can be generated for each member state in EU27, for the period between 2010 and 2020. For the purposes of this research, material flows to be considered are:

-

Imports (IMP) of materials from outside the aggregate EU27 or one of the member states, including imports of waste (\(IMP_W\)),

-

Exports (EXP) of materials to outside the aggregate EU27 or one of the member states, including exports of waste (\(EXP_W\)),

-

Direct Material Inputs (DMI), the sum of Imports (IMP) with Domestic Extraction (DE),

-

Processed Materials, or \(PM = DMI + RCV_R\),

-

Domestic Material Consumption, or \(DMC = PM - EXP\),

-

Material Use that can become stock or discarded, reaching EoL,

-

Waste treatment, performed through incineration, landfilling, backfilling or recycling: \(TRT = EoL - EXP_W + IMP_W\).

-

Waste Recovered (no backfilling), or \(RCV_R\) in Eurostat’s nomenclature.

Computing CMU for smaller regions or municipalities leads to uncertainties due to lack of official data like Domestic Material Consumption (DMC) [23, 24]. This problem can be overcome by estimating lower-level data taking advantage of other available data - a process called downscaling [25]. Ratio-based estimates are considered good predictors; sophisticated estimation techniques do not necessarily lead to better results [24]. Towa et al. [26] proposed a framework to generate multiregional input–output tables, applying the framework and the data in the assessment of the circularity of the regions of Brussels, Flanders and Wallonia [27]. Combining empirical data with estimates, Noll et al. [28] applied the sociometabolic approach for the island of Samothraki, Greece, and derived a time series for material flow volumes from 1929 until 2019. Cycling rates were also computed for input and output flows, and a comprehensive analysis of the island circularity was provided, as well as recommendations for improvement in different material flow categories.

On the micro-level, resource circularity indexes were proposed to model product lifecycle or production footprint. With methodologies for both the product and company-level, the Material Circularity Indicator (MCI) [29] is aimed at companies whose product production processes span across multiple departments. MCI also accounts for product lifespan, making it incomparable with higher-level indexes like the CMU. Brändström and Eriksson [30] attempted to connect circularity metrics with sustainable performance, for different levels of analysis, starting from circular business models and design strategies. The metric quantifies gains achieved after the implementation of a strategy, therefore requiring a “as-is” and a “to-be” situation for its calculations. The authors claim that, due to its value chain perspective, the approach can be extended to the meso-level; however, no demonstration was provided.

In addition to the initiatives advancing downscaling or monitoring resource circularity in one level of analysis, multi-level frameworks have been proposed by the scientific community. Barrera et al. [31] developed a theoretical framework that reviews the concept of urban metabolism for energy dynamics. However, their framework has been contested in Arbabi et al. [32] for lacking depth in their literature review, omitting contributions from scientific communities currently investigating this topic. Beyond the theoretical realm, Bianchi et al. [13] proposed a regional monitoring framework using three case studies, based on Econometrics and territorial metabolism. They argue that national monitoring frameworks provide limited help for regional contexts, while failing to provide all data required. Eighteen indicators were monitored, however resource circularity was not analysed in their study.

In none of the reviewed indexes or frameworks, reuse, repair, refurbish, remanufacture and re-purpose - the PfR flows - have been properly addressed. PfR flows are briefly introduced in the following section.

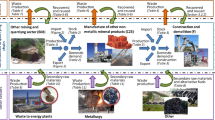

Preparation for Reuse and the Circular Economy

PfR strategies can have a positive influence on the environmental, social and economic performances of a system, as long as product reusability is not overestimated [12]. A standard nomenclature for recovery options has been defined, as well as the hierarchy for value retention in the context of the Circular Economy [15]. Figure 10 illustrates the “Circular Economy 3.0”, expanding the 3R concept - reuse, repair and recycle. The Figure illustrates linear flows of mining, material production, component production, end product manufacturing/brand, retailing, consumption, collection, landfilling, and the recovery strategies of refuse (R0), reduce (R1), reuse (R2), repair (R3), refurbish (R4), remanufacture (R5), repurpose (R6), recycling (R7), incinerating (R8), and landfill mining (R9) - the 10R hierarchy.

There is a high potential to recover material through PfR, shifting waste recovery practices towards recovery strategies higher in the waste hierarchy defined by the European Council [33]. For example, in the German state of Bavaria, there is a potential of recovering 45% of Waste Electric and Electronic Equipment (WEEE), furniture and leisure goods through PfR, instead of recycling [9]. Locally, this potential has been realised by Urban Resource Centres (URCs), organisations gathering a wide community of stakeholders in urban areas to drive sustainable consumption, waste prevention, re-use, repair and recycling [16]. These URCs are normally social enterprises, non-profit or community-based organisations.

Lately, URCs have emerged in Europe in the form of Repair Cafés, Repair Shops like the Belgian Kringwinkels [34], and the Halle2 in Munich (https://www.awm-muenchen.de/vermeiden/halle-2 awm-muenchen.de/vermeiden/halle-2). In [16], twelve initiatives of URCs across Europe were listed, as well as drivers and barriers for their operation. The simplistic depiction of an URC in Fig. 11 offers examples of functions an URC can perform in the environmental (waste prevention and source of secondary materials), social (job creation and community engagement), and economic (incubator) dimensions.

After reviewing how resource circularity has been quantified, what are the PfR flows and who are the organisations facilitating it, the following section describes how these elements are combined to produce solutions to the problems identified.

Methodology

This work progresses what was proposed in [35] by switching the general framework from [36] to [15], since the latter is more focused on CE and PfR. The SD and the CMU are approached as design artefacts, and Design Science Research [37, 38] is employed to define solutions and demonstrations to the problems and objectives detailed in the previous sections, as summarised in Fig. 2. In Sect. 4.1, the circular SD and the LCR are described. Mathematical expressions for LCR are defined for the macro- and meso-levels, followed by a description of the material flow model used to compute the LCR in the micro-level. In Sect. 4.2, cases of application to showcase the calculation and analysis of LCR in the macro-, meso- and micro-levels are detailed.

Circular Sankey Diagram and LCR

The Eurostat SD from Fig. 9 is redrawn based in the CG approach from Fig. 1, developed in sankeyflowshow, using EUCEMF’s nomenclature whenever possible. Material flows are reallocated based in the SDs of Towa et al. [26]. To account for PfR flows, a few quantities are added to the diagram. Stock Degradation (StkDeg) are products that were accumulated in stock (StkAcc) and lost utility, reaching EoL. This flow is featured in Eurostat dataset ENV_AC_SD, but figures can only be found for Bulgaria and Greece. EoL sums all waste generated and/or collected - assuming all waste generated is collected -, and splits in waste exports and waste locally treated. Waste Treatment process (TRT) follows suit, an aggregate of locally treated waste and waste imports. Two PfR flow groups are added: Short Loops, gathering reused and repaired products, and Medium Long Loops, gathering refurbished, remanufactured and repurposed products. These flows are outputs of TRT and inputs to Products Recovered (\(RCV_P\)), which in turn is an input for Material Use.

The computation of LCR in the lower levels of analysis is performed using symbols listed in Table 1. Set T represents the years evaluated. Macro-, meso- and micro-level are equivalent to country-, regional- and network-level, respectively. EU27 is aggregated in the macro-level under set C. The meso-level is in superset M containing three intermediate levels, following the NUTSFootnote 1 hierarchy. Sets F, G and H gather NUTS-1, 2 and 3 regions, respectively. RCNs are aggregated under set K. Another three sets are defined to allow for generalisation of the equations: superset Y, containing all five possible levels of analysis, Z, the subset of elements z belonging to a higher level than objects in level y, and set \(Y_z\) of elements y belonging to z. For example, set \(K_g\) is the set of all RCNs located in the g-th NUTS-2 region; set \(H_c\) is the set of all NUTS-3 regions located in the c-th country. Set J gathers material destination flows, following Reike et al. [15]: Resell/Re-use (2), Repair (3) Refurbish (4), Remanufacture (5), Repurpose (6), Recycle (7) and Incineration (8). Flows destined for cannibalisation comes next (9) and last, landfill (10). Subset \(J_r\) gathers only material recovery flows, i.e. from re-use to recycle. Finally, set L gathers material flows, and set A is a set of databases used in the computation of LCR for the sixteen German states: DESTATIS (d) and eurostat (e).

LCR is computed using quantities derived from CMU. \(SM^\prime \) and \(OMU^\prime \) are defined adding PfR flows to the original SM and OMU - originally including only recycling flows -, expressed in Equations 2 and 3 respectively. Recycled materials \(RCV\_R\) is one of the terms of \(\sum _j^{J_r} o_j\), recovered outputs of waste treatment. EoL for a given locality can be retrieved from databases or reports, or computed using Equation 4, where \(\sum _j^J EXP_j = EXP\_W\) and \(\sum _j^J IMP_j = IMP\_W\). LCR is computed through Equations 5 to 8, in terms of \(\alpha \), the EoL to Overall Material Use ratio (EoL-to-OMU); \(\beta \), the treated waste to EoL ratio (TRT-to-EoL); and \(\gamma \), the ratio of recovered waste from the treated waste (RCV-to-TRT), or the recovery rate. Cancelling the terms TRT and EoL, it is possible to express LCR through Equation , where it will be equal to CMU when imports cancel out with exports, i.e., \(SM^{\prime }\) \(= SM\) it should be italic and \(M^\prime = M\).

To formulate expressions for LCR in the micro-level, a material flow model was developed around the concept of Resource Circularity Networks, as described in the next subsection.

The Resource Circularity Network Material Flow Model

The generic Resource Circularity Network (RCN), modelled using STAN2WEBTM, is depicted in Fig. 3. The RCN includes in its scope processes of collection, cannibalisation of waste (i.e. scrapping valuable parts and materials from waste [15]), recycling, repairing, retailing, refurbishing, repurposing and remanufacturing. Based in Braziotis et al. [40], we can define the Resource Circularity Network as a star-shaped network aimed at recovering waste, composed by an URC as the central hub and its interacting tier-1 agents. These agents interact with the URC, with each other, and with the environment exchanging material flows. The URC functions as a hub in the RCN, performing processes of acquiring/receiving, sorting, repurposing, repairing and checking/selling. Refurbishable, remanufacturable and recyclables are forwarded to other organisations. Products that cannot be repurposed, repaired or re-sold by the URC are also forwarded to 3rd-party organisations. A dashed rectangle delimits the RCN from the surrounding environment; flows entering and leaving the RCN are imports I and exports E, respectively.

Material flows are organised in three categories: inputs \(i_{j,l}\), outputs \(o_{j,l}\), and intermediate flows exchanged within the RCN, \(q_{j,l}\). All flows are listed in Appendix B, identifying the source and destination of each flow. Eighteen inputs, twelve intermediate flows and twelve outputs are listed. For each flow, a j-th recovery strategy and an l-th sequential index are defined and indicated. Flows \(i_{J,1}\) and \(q_{J,1}\) mean that since the recovery strategy is undefined, all potential recovery types are summed. Some inputs in the table are represented by one arrow in the diagram, for example, waste coming from material production, component production, product manufacturing and retailing is coded \(i_{J,L}\). Flows coming from the URC are assigned \(l=1\). Intermediate flows coming from the collection process are assigned \(l=0\). Products made available for consumption by the URC are represented in flow \(o_{2,1}\).

Expressions for \(U^\prime _k\) and \(M^\prime _k\) are the same as Equations 2 and 3, where \(y = k\) for the network level under analysis—assuming that material flows are conserved. Waste treated, \(TRT_k\), is all waste recovered plus all waste with a linear destination, as expressed in Equation 10. EoL is considered the sum of all inputs in the RCN as expressed in Equation 11. In the network-level, the difference between both quantities means there are stocks within the RCN. Hence, \(\alpha _k\), \(\beta _k\), \(\gamma _k\) and \(LCR_k\) are computed using Equations 5 to 8. The share of contribution of the URC for the total material recovered by an RCN, \(urc_k\), is modelled in Equation 12, as the sum of recoverable inputs provided by the URC, divided by the total amount of materials recovered by the RCN, \(U^\prime _k\).

Demonstration

Cases of application in different levels of analysis are used to verify the implications of adopting LCR instead of CMU and to demonstrate the calculation process of LCR, including the usage of the RCN model. 2018 was the year considered for the analysis since it is the last year in Eurostat where data is consolidated - all data available afterwards is an estimate. In the macro-level, the circular SD is modelled for Denmark; LCR figures are computed for every member state in EU27, broke down in three fractions - EoL-to-OMU, TRT-to-EoL and RCV-to-TRT - and discussed. In the meso-level, LCR is computed using i) estimates generated using data from official national statistics for all NUTS regions in Germany, ii) data from scientific literature for all NUTS regions for Belgium, iii) official regional data for Amsterdam and iv) scientific data for Samothraki. In the micro-, network-level, a case of an URC recovering textiles in Amsterdam is translated into the RCN framework for calculation of the \(LCR_k\) and \(urc_k\). These cases are described in the following subsections.

Macro-level: country-level circular SD, metrics comparison and breakdown analysis of EU27 member states

The new circular SD for Denmark, 2018, is modelled using data from the original SD of Fig. 9 and from Eurostat databases ENV_AC_MFA, ENV_AC_SD, ENV_WASTRT and ENV_WASSD. Although Denmark was chosen as a case of application, this demonstration can be performed for any EU27 member state or the aggregated EU27. To compare the metrics, figures for LCR, CMU and \(CMU^\prime \) are computed for all member states of EU27 for 2018, following Equations 2 to 8 and the CMU’s official method [6]. The differences between CMU and CMU’, and between CMU and LCR are compared for 2018 for all member states in EU27 and the EU27. Average standard deviations for EU27 member states are analysed for even years, from 2010 until 2018. Figures for \(\alpha \), \(\beta \) and \(\gamma \) are computed for every EU27 member state and countries are ranked according to their performance.

Meso-level: Regional Circularity

Using available data, three cases of application are developed. First, LCRs are computed for Germany’s NUTS-1 regions using data obtained in GENESIS, the online database of the German national statistics office DESTATIS. CMU and CMU’ are also computed for all regions to stress the need for an alternative circularity index. Second, results from Towa et al. [26] are used to compute LCR for Belgium and the NUTS-1 regions of Flanders, Wallonia and Brussels. LCR is computed for Samothraki, a Greek island, using the results from Noll et al. [28] and for the city of Amsterdam, using data from the municipality’s official portal: Onderzoek en Statistiek.

Table 2 contains data generated and used to compute LCR for Germany’s NUTS-1 regions. Data retrieved from Eurostat and DESTATIS are labelled with indexes e and d, respectively. Figures retrieved for Germany for TRT, \(RCV_R\), \(EXP_W\) and \(IMP_W\), diverged between Eurostat and DESTATIS. Therefore, two LCRs are computed, one for each database, and differences between figures are discussed. CMU and CMU’ are also computed to compare the differences. Regional data for DMC, \(TRT_e\), \(RCV_R\) and EoL are estimated. DMC is downscaled using official GDP per capita in Germany and regional population, as expressed in Equation 14. \(\widehat{TRT}_{f,e}\) is generated from \(TRT_{f,d}\) through Equation 15. \(TRT_{f,d}\) is retrieved from dataset 32111-0010, field Input to waste treatment plants, for each NUTS-1 region.

Values for \(\widehat{RCV}_{f,a}\) are generated iterating \(\gamma \) and RCV, assuming that the sum of regional RCVs is equal to the country-level RCV, \(\sum RCV_{f,a} = RCV_{c,a}\). An initial \(RCV_{f,d}\) is determined summing quantities Wastes to be recovered with Distribution to other plants, users or traders from dataset 32111-0011, subtracting the portion distributed to thermal and combustion plants. Initial recovery rates are computed for all sixteen regions using \(\gamma _{f,d} = \frac{RCV_{f,d}}{TRT_{f,d}}\). An upper-bound for recovery rate, \(\epsilon = 0.8\), is used to enhance consistence of the estimates. This value is based in the highest value computed among countries: 0.7926 by Italy, in 2018. If \(\gamma _k\) surpasses \(\epsilon \), \(\epsilon \) is used instead to generate the estimate.

For the Eurostat estimates (e), one round of iteration was sufficient to match the sum of regional RCVs with the national RCV, through Equations 19 and 16. For the DESTATIS estimates (d), another round of iteration for \(\gamma \), \(\gamma ^{\prime \prime }\) and two iterations of RCV were needed, \(RCV^{\prime \prime }_{f,d}\) and \(RCV^{\prime \prime \prime }_{f,d}\), obtained via Equations 19, 21, 20, 17 and 18, respectively. \(\widehat{RCV}_{f,a}\) are determined using Eq. 13. \(\Lambda \) is a set containing all regions in which \(\gamma _{f,d}^\prime \) is below 0.8. For the other regions, \(\widehat{RCV}_{f,a}\) will be simply 0.8 multiplied by \(TRT_{f,d}\).

\(\widehat{EoL}_{f,a}\) is determined using Equation 22. \(EoL_{y,d}\) is Quantity of Waste Produced, retrieved from dataset 32161-0004. \(\widehat{EoL}_{f,d}\) is obtained iterating \(EoL_{f,d}\) up to the aggregated Waste accumulation total for Germany, \(WAC_{c,d}\), obtained from the official Waste balance 2018. \(\widehat{EoL}_{f,e}\) is determined iterating \(\widehat{EoL}_{f,d}\), using \(EoL_{c,e}\) obtained from Eurostat. Exports of waste for the other states within Germany, \(EXP_{W,f,d,i}\), is determined subtracting waste generated locally, \(TRL_{f,d}\) and waste exported to foreign countries, \(EXP_{W,f,d,a}\) from \(EoL_{f,d}\). \(TRL_{f,d}\) is obtained from dataset 32111-0010 and \(EXP_{W,f,d,a}\) is obtained from Transboundary Movement of wastes, subject to notification, from Germany by land and years. Amounts in 1,000 tonnes, for 2018. \(\widehat{EXP}_{W,f,d}\) is interpolated for every region through Equation 23, considering that total imports of waste within the German territory should be equal to the total waste exports. The official quantity for waste imports, \(IMP_{W,f,d,i}\), is obtained from 32111-0010.

Estimates for waste trade balance, \(WTB = EXP_W - IMP_W\), are determined for DESTATIS, and by interpolation for Eurostat using Eq. 24. Waste trade balance for Germany retrieved from DESTATIS, \(WTB_{c,d}\), is negative, while retrieved from Eurostat, \(WTB_{c,e}\), is positive. Therefore, estimates for each region Eurostat are interpolated separately, where all negative quantities are grouped in subset \(\Omega ^-\), and all positive quantities in subset \(\Omega ^+\). The sum of all positive balances with the sum of all negative balances has to be equal to the net trade balance in the aggregate level, as expressed by Eq. 25. Finally, \(\widehat{CMU}_{f,a}\), \(\widehat{CMU}_{f,a}^\prime \) and \(\widehat{LCR}_{f,a}\) are determined using Equations 26, 27 and 28, respectively.

Data collected from scientific literature used to compute LCRs for Brussels, Flanders, Wallonia, Samothraki and Amsterdam are summarised in Table 3. For the Belgium regions, all data used is exclusively taken from [28], since all quantities were readily available. Values for Belgium are aggregated from the regions; no estimates or calibration with Eurostat’s figures are performed. For Samothraki, the only data missing is waste imports. In this case, it is assumed that no waste is imported to the Greek island. EoL is available; TRT is computed through Equation 4. For Amsterdam, RCV is obtained multiplying the official recycling rate by the amount of waste treated; EoL is obtained using Equation 4. Results for Samothraki and Amsterdam are also compared and discussed with national results for Greek and The Netherlands, respectively. WTB were obtained replacing DMC, \(RCV_R\) and CMU by its corresponding values in Eq. 1.

Micro-level: Amsterdam Textiles

To demonstrate the usage of the RCN material flow model, we adopt a study from the Reflow Project (reflowproject.eu), Textile (life)cycling in Amsterdam, The Netherlands. The SD from Fig. 12, developed by the Reflow Project and Metabolic (metabolic.nl), depicts flows and processes of Raw Materials, Textiles Production, Distribution, Consumption, Collection and EoL. Collection is performed via municipal waste bins, collection containers or from the industrial waste stream. Textiles collected via containers are forwarded to and sorted by a Textile Sorting Centre run by a charity organisation contracted by the City of Amsterdam. In the diagram, material flows entering and leaving that organisation are indicated as “URC”. Some quantities originally omitted in the diagram, but required for modelling, are also indicated.

Data collected from the diagram is reported in Table 4, Quantities originally omitted in the diagram are highlighted - estimated using Eqs. 29a to 29d. The following assumptions are made: all retail waste is reused; all unknown waste is considered landfilled; all losses sent for recycling or incineration comes from material production; all losses from production and retailing are considered re-used; last, all waste “exported as-is” is considered for incineration.

Results

Results are organised from the macro- to the micro-level perspective. First, the redesigned SD is presented. CMU, CMU’ and LCR are reported, analysed and discussed in the meso-level for NUTS regions. Finally, resource circularity results for the micro-level case of the Amsterdam textiles are presented.

Denmark’s Circular Sankey Diagram

Figure 4 depicts the expanded, circular material flow SD for Denmark, 2018. Flows represented as dotted lines are omitted in the original SD. An alternate \(DMI^\prime \) is defined excluding imports of waste, \(IMP_W\). Processed Materials is modified; therefore, \(PM^\prime \) is used instead. DMC is explicitly represented, as well as the EoL phase, i.e., the quantity of waste collected, considering all waste generated is collected. DMC and Material Use differ substantially: 139 against 102 Mtonnes, respectively. This difference is accounted as losses, along with a remaining flow of 13.2 Mtonnes for which no information could be retrieved - represented by a blank, dashed line arrow. Without accounting for incineration, now allocated as “linear waste”, 51 Mtonnes are lost as emissions and dissipative flows.

The upgraded SD for Denmark, 2018, using the CG approach (created with sankeyflowshow)

Material Use, Stock Accumulation, Waste recovered \(RCV_R\) and backfilling remain unchanged in Fig. 4. Exports of waste \(EXP_W\) are now an output of the EoL phase. Imports of waste \(IMP_W\) are an input for the next phase of Waste Treatment (TRT). The remaining quantity of waste landfilled, incinerated or not recovered is agglutinated in a single flow, Linear Waste. Waste recovered through recycling, \(RCV_R\), is an input to the “make” phase of \(PM^\prime \). PfR flows (PfR) are outputs of the Waste Treatment phase and are organised in two streams: short loops stream, gathering Resell/Reuse and Repair flows (R2 and R3, respectively) and medium long loops stream, representing flows of refurbishing, remanufacturing and repurposing - R4, R5 and R7, respectively. PfR flows are gathered in the Products Recovered flow, \(RCV_P\), a new input for Material Use. The unrecovered fraction, or the CG, is represented in the empty space between backfilling and PfR flows.

Comparison Between CMU, CMU’ and LCR

Figure 5 illustrates the difference between CMU and \(CMU^\prime \), and between CMU and LCR, for all 27 member states of the EU and the overall EU27, in light and dark grey respectively, for 2018. Biggest differences are, as expected, observed for countries where the waste trade balance and local waste amounts are closer, like Luxembourg, Slovenia (waste importers), Latvia and Malta (waste exporters). Table 5 shows, for every second year from 2010 until 2018, the percentage difference in Standard Deviations between \(CMU - CMU^\prime \) and between \(CMU - LCR\). Again, the latter shows smaller differences than the former.

Analysing alpha, beta and gamma for EU27 member states

A bubble chart with all EU27 member states, ranked by \(\alpha \) and \(\gamma \), is represented in Fig. 6. \(1 - \beta \) is used for bubble sizing, therefore normalising to zero the relative difference between countries. Countries represented by black bubbles have a positive waste trade balance (WTB), while countries with a negative WTB are represented by white-filled bubbles. The chart is divided in four quarters: upper-right green, for countries featuring \(\alpha \) and \(\gamma \) above 0.4. In the lower-left yellow quarter are countries with both \(\alpha \) and \(\gamma \) below 0.4. In the upper-left and lower-right blue quarters are countries with a performance of either one of the indexes above 0.4, but a performance of less than 0.4 in the other index. The value of 0.4 is used as boundaries for the quarters as they are roughly halfway to the highest performances recorded in each index: 0.8131 for \(\alpha \) and 0.7926 for \(\gamma \).

Luxembourg and The Netherlands are the only countries in the green quarter of Fig. 6. While the former imports a lot of waste, the latter has a positive WTB and features the second-best performance in \(\alpha \). In the upper-left quarter, countries showing best \(\gamma \) are Italy and Belgium, with France showing the best performance in \(\alpha \). Other countries in this quarter are: Hungary, Latvia, Denmark, Croatia, Portugal, Czech Republic, Poland, Slovenia and Germany, making a total of twelve countries in this quarter. In the lower-right quarter, countries with the worst performance in \(\gamma \) are Romania and Bulgaria - the latter showing the highest \(\alpha \) of all EU27 member states. Other countries in this quarter are: Estonia, Sweden and Finland, making a total of five countries. Overall, seventeen out of twenty-seven countries are in the blue quarters. The remaining eight countries are in the bottom-left quarter, with Ireland showing very low performance in both indexes. Other EU27 member states in this quarter are also Austria, Malta, Greece, Cyprus, Spain, Slovakia and Lithuania.

Computing CMU, CMU’, LCR for NUTS Regions

Table 6 shows the results for \(CMU_e\), \(CMU^\prime _e\), \(LCR_e\) and \(LCR_d\), for all sixteen NUTS-1 regions of Germany. Negative results are found for CMU (seven regions) and \(CMU^\prime \) (five regions). Using Eurostat data, average LCR is 12.4%; using DESTATIS data, the average is 20.2% - a difference of 7.8%. Notably, the lowest and highest performing state are the same, regardless of the data used. Saxony-Anhalt is at the top of the list with LCR estimates of 29.8 % and 38% (Eurostat and DESTATIS respectively); Berlin is at the bottom of the list with LCR estimates of 5.2% and 7.2%, respectively. However, some regions changed rankings considerably from one estimate to the other. For example, Thuringia jumps from thirteenth to third; North Rhine-Westphalia drops from fourth to thirteenth. The biggest difference between estimates is found for Thuringia (15.8%) and the smallest for Berlin, 2%.

Finally, Fig. 7 shows values for \(\alpha \), \(\beta \), \(\gamma \) and LCR for five NUTS regions where data is retrieved from literature: Flanders, Wallonia, Brussels, Samothraki and Amsterdam. \(\alpha \), \(\gamma \) and LCR are plotted as columns against the primary axis on the left of the chart. \(\beta \) is plotted as a dashed line with rounded markers against the secondary axis, to the right of the chart. Flanders and Wallonia show similar levels of \(\alpha \), both significantly higher than Brussels.

Samothraki shows the highest \(\alpha \), but a low \(\gamma \) drives LCR to a low value of 2.3%. Amsterdam shows the lowest value for \(\alpha \). The city features a positive WTB and a higher recovery rate, with a \(\beta \) of 1.66, against 0.98 from the Netherlands, and a \(\gamma \) of 47% against 43%. Comparing their \(\alpha \) shows the main difference: 9.5% for Amsterdam and 66% for The Netherlands.

LCR of Amsterdam Textiles

Figure 8 shows the material flows from the SD of the Amsterdam Textiles translated into the RCN model. Processes coloured in grey are inactive: remanufacturing, repurposing, refurbishing, repairing and cannibalisation. Material flows in grey are considered equal to zero. Some material flows are split, like \(o_{8,1}\), the output of URC for incineration, to allow for identification of the material flows. EoL, TRT, \(\alpha \), \(\beta \), \(\gamma \) and LCR for the network are computed below. A recycling rate of 19.2% with an LCR of 12.3% are achieved. The URC provides 62.7% of all textiles recovered in Amsterdam.

Discussion

In the macro-level, a circular SD for Denmark better illustrates how resource circularity evolves, compared with the existing linear SD in Appendix C. In addition, it also indicates which PfR flows still require data, covering the scope of possible recovery strategies in the waste hierarchy [33], and therefore, providing a comprehensive picture of the actual NCG. WTB will not influence LCR unless the country or region under analysis is importing waste for PfR, not for e.g. production of electricity. In this case, these countries will feature a higher LCR compared to countries exporting waste for PfR.

Distortions on CMU can already be observed in the country-level, re-instating the need for an alternative metric to CMU or \(CMU^\prime \) for lower levels of analysis. Bianchi et al. [13] observed that Luxembourg’s circularity performance would be considerably improved using an indicator that rewards secondary material internally reused. Overall, differences between CMU and LCR are smaller than between CMU and \(CMU^\prime \), as observed in Fig. 5 and comparing standard deviations (SD) reported in Table 5. For every second year from 2010 until 2018, the percentage difference between \(CMU - CMU^\prime \) is around twice as much as of \(CMU - LCR\), stating the higher comparability of LCR to CMU, rather than \(CMU^\prime \). This comparison highlights a limitation of LCR: it cannot be interchangeable with CMU when the ratio between WTB and OMU is significant. However, this is only the case for Luxembourg and Malta; for the other twenty-five countries in the EU27, such interchangeability still holds.

Comparing the breakdown of LCR of EU27, only The Netherlands and Luxembourg are in the upper right quarter of Fig. 6, i.e., have both \(\alpha \) and \(\gamma \) above 0.4. In the meso-level, negative results for CMU and CMU’ where found for twelve NUTS-1 regions in Germany, out of sixteen, evidencing their unsuitability for downscaling. For Samothraki, results differ considerably from Noll et al. [28] which considers circularity of inputs as a ratio of secondary materials from PM, and circularity of outputs as a ratio of secondary materials from the intermediate output [42]. In the micro-level, PfR flows of textiles in Amsterdam, allocated using the RCN model, make up for an LCR of 12%, where the URC contributes with roughly two thirds of all textiles recovered.

For all German states, greater values are found for \(LCR_d\) comparing to \(LCR_e\), an expected outcome since \(RCV_{d}\) is higher than \(RCV_{e}\), while DMC is the same for both. For Flanders and Wallonia, LCR computed where 9.1% and 9.9%, respectively, while Towa et al. [27] found a circularity of 6.3% and 8.1%. The equation used in that research computes resource circularity summing imports with domestic extraction as denominator, instead of DMC (\(DE + IMP - EXP\)) plus RCV [6]. Results matched for Brussels’ LCR, 0%, since no local recovery flow is reported. These results would probably be different if PfR flows were considered, since Kringwinkels, a network of URCs, have been recovering products in the whole Belgium since the mid-90s [34, 43].

Across levels, the difference in LCR between Amsterdam and the Netherlands is due to \(\alpha \), or the EoL-to-OMU ratio. A possible explanation is that Stock Accumulation is substantially higher in Amsterdam than in the rest of the country. These results cannot be directly compared with what was achieved by Sileryte et al. [11], due to substantial differences in the order of magnitude between data used. That research reported that waste treated locally in Amsterdam is 2,135 Mtonnes, while the official amount of waste treated in the whole Netherlands in that same year was 144 Mtonnes [44] - almost fifteen times smaller.

Conclusion

This research proposes an upgrade in the EU’s circular economy monitoring framework, specifically in the material flow SD and the Circular Material Use Rate, the CMU. A new circular SD is proposed, accounting for PfR flows. Based on CMU, an alternate index is proposed, the LCR, to allow for cross-scaling comparison between countries, regions, cities and networks. Differences between the LCR and the official CMU - including its alternate version, the CMU’ - are clearly stated, mitigating risks of misuse while demonstrating how to compare both indexes and accounting for the limitations. LCR’s partial ratios, \(\alpha \), \(\beta \) and \(\gamma \) allows countries to identify the most critical aspects of resource circularity, improving prioritisation of strategies and public policies.

In the micro-level, material flows are modelled using STAN2WEB\(^{\textsc {tm}}\), based in RCNs and URCs. These new artefacts are demonstrated in the macro-, meso- and micro- level. Conditions for comparing resource circularity in the macro-level of nations down to the micro-level of RCNs are defined. The pivotal role of the URC as a driver of CE is observed in the magnitude of its contribution to the overall material recovered, stemming from being at the core of the RCN. The expansion of scientific literature and data availability about URCs may lead to revisions of such framework in the future.

Currently, the applicability of LCR is limited to the EU region, depending on EU’s definitions of material flows and geographical divisions. The NUTS regions provided a consistent structure to model nested, geographic levels within the complex material flow system. Despite being a major advocate of CE, there is still a lack of data systematisation in most countries in the EU27, increasing the uncertainty of results achieved. It was not until very recently that PfR flows could be found in Eurostat, and only for France. To this date, figures for WTB, for example, are too difficult to be retrieved, which prevents policy makers to adopt such an index. Another barrier to use such factor concerns waste databases: information across regional and national databases are still non-standardized.

A rather simplistic process to generate estimates was developed than what has been employed [26,27,28]. In the future, this research can be expanded to include EXIOBASE as a data source; accuracy of DMC estimates can be improved using, for example, the method of Bianchi et al. [45]. Nevertheless, using LCR, \(\alpha \), \(\beta \) and \(\gamma \) as upper bounds for intermediate quantities improved the quality of estimates. For example, assuring that the quantity of recovered waste is smaller than the quantity of treated waste, and that the quantity of EoL waste is smaller than the sum of DMC with RCV.

It is unlikely that 100% circularity can be achieved due to thermodynamic limitations [4] - it remains unclear what is the maximum value that could be realistically achieved. In the other hand, it may not even be desirable since it could bring implications to a system’s resilience, e.g., fragility [46]. In the other hand, the inclusion of PfR increases the diversity of flows in the system, potentially mitigating such effect and ultimately improving the system’s resilience.

Data availability

Data used in this research is available for download at the Project’s Open Science Framework Repository.

Notes

Nomenclature of Territorial Units for Statistics [39].

References

de Wit, M., Hoogzaad, J., von Daniels, C.: Circularity Gap Report 2020. Technical report, Circle Economy, Amsterdam (2020). https://www.circularity-gap.world/

Circle Economy: Measuring and Mapping Circularity. Technical methodology document. Circle Economy, Amsterdam (2020). https://assets.website-files.com/5e185aa4d27bcf348400ed82/5e4d0a24eb0887b1ddfa59b9_MeasuringandMappingCircularity-technicalmethodologydocument.pdf

Commission, E.: Circular Economy Monitoring Framework (2020). https://ec.europa.eu/eurostat/web/circular-economy/indicators/monitoring-framework. Accessed 19 May 2020

Bartie, N.J., Cobos-Becerra, Y.L., Fröhling, M., Schlatmann, R., Reuter, M.A.: The resources, exergetic and environmental footprint of the silicon photovoltaic circular economy: assessment and opportunities. Resour. Conserv. Recycl. 169, 105516 (2021). https://doi.org/10.1016/J.RESCONREC.2021.105516

Union, E., European Commission: Circular economy action plan. European Commission, 28, (2020). https://doi.org/10.2775/855540

Eurostat: Circular Material Use Rate- Calculation Method 2018 edition. Technical report, Eurostat (jan 2018). https://doi.org/10.2785/132630. https://ec.europa.eu/eurostat/about/policies/copyrighthttps://ec.europa.eu/eurostat/documents/3859598/9407565/KS-FT-18-009-EN-N.pdf/b8efd42b-b1b8-41ea-aaa0-45e127ad2e3f

Eurostat: Circular economy flow diagrams (2021). https://ec.europa.eu/eurostat/cache/sankey/circular_economy/sankey.htmlhttps://ec.europa.eu/eurostat/cache/sankey/circular_economy/sankey.html?geos=EU27 &year=2019 &unit=MIO_T &materials=TOTAL &highlight= &nodeDisagg=0101100100 &flowDisagg=true &translateX=200 &

Comission, E.: Waste Framework Directive. https://environment.ec.europa.eu/topics/waste-and-recycling/waste-framework-directive_en Accessed 2023-05-10

Messmann, L., Boldoczki, S., Thorenz, A., Tuma, A.: Potentials of preparation for reuse: a case study at collection points in the German state of Bavaria. J. Clean. Prod. 211, 1534–1546 (2019). https://doi.org/10.1016/j.jclepro.2018.11.264

Boldoczki, S., Thorenz, A., Tuma, A.: The environmental impacts of preparation for reuse: a case study of WEEE reuse in Germany. J. Clean. Prod. 252, 119736 (2020). https://doi.org/10.1016/j.jclepro.2019.119736

Sileryte, R., Sabbe, A., Bouzas, V., Meister, K., Wandl, A., van Timmeren, A.: European waste statistics data for a circular economy monitor: opportunities and limitations from the Amsterdam metropolitan region. J. Clean. Prod. 358, 131767 (2022). https://doi.org/10.1016/J.JCLEPRO.2022.131767

Gusmerotti, N.M., Corsini, F., Borghini, A., Frey, M.: Assessing the role of preparation for reuse in waste-prevention strategies by analytical hierarchical process: suggestions for an optimal implementation in waste management supply chain. Environ. Dev. Sustain. 21(6), 2773–2792 (2019). https://doi.org/10.1007/s10668-018-0160-9

Bianchi, M., Cordella, M., Menger, P.: Regional monitoring frameworks for the circular economy: implications from a territorial perspective. Eur. Plan. Stud. (2022). https://doi.org/10.1080/09654313.2022.2057185

Eurostat: Circular economy - material flows (2021). https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Circular_economy_-_material_flows#How_the_circularity_rate_is_related_to_the_Sankey_diagram. Accessed 10 June 2022

Reike, D., Vermeulen, W.J.V., Witjes, S.: The circular economy: new or refurbished as CE 3.0? - Exploring controversies in the conceptualization of the circular economy through a focus on history and resource value retention options. Resour. Conserv. Recycl. 135(November), 246–264 (2018). https://doi.org/10.1016/j.resconrec.2017.08.027

Partnership on Circular Economy: Urban Resource Centres: A classification of local approaches to waste prevention, re-use, repair and recycling in a circular economy. Technical report, Urban Agenda for the EU (2019). https://doi.org/10.1177/095624789400600113

Corona, B., Shen, L., Reike, D., Rosales Carreón, J., Worrell, E.: Towards sustainable development through the circular economy—a review and critical assessment on current circularity metrics. Resour. Conserv. Recycl. 151, 104498 (2019). https://doi.org/10.1016/j.resconrec.2019.104498

Haas, W., Krausmann, F., Wiedenhofer, D., Heinz, M.: How circular is the global economy?: An assessment of material flows, waste production, and recycling in the European Union and the world in 2005. J. Ind. Ecol. 19(5), 765–777 (2015). https://doi.org/10.1111/JIEC.12244

Circle Economy: About - Circularity Gap Reporting Initiative (2022). https://www.circularity-gap.world/about. Accessed 28 July 2022

Eurostat: Indicators (2022). https://ec.europa.eu/eurostat/web/circular-economy/indicators. Accessed 11 Mar 2022

Eurostat: Domestic Material Consumption (2022). https://ec.europa.eu/eurostat/databrowser/view/ENV_AC_MFA__custom_3234996/default/table?lang=en &category=cei.cei_srm Accessed 26 Aug 2022

Eurostat: Domestic material consumption (DMC) (2017). https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Glossary:Domestic_material_consumption_(DMC). Accessed 11 Mar 2022

Voskamp, I.M., Stremke, S., Spiller, M., Perrotti, D., van der Hoek, J.P., Rijnaarts, H.H.M.: Enhanced performance of the Eurostat method for comprehensive assessment of urban metabolism: a material flow analysis of Amsterdam. J. Ind. Ecol. 21(4), 887–902 (2017). https://doi.org/10.1111/JIEC.12461

Horta, I.M., Keirstead, J.: Downscaling aggregate urban metabolism accounts to local districts. J. Ind. Ecol. 21(2), 294–306 (2017). https://doi.org/10.1111/JIEC.12428

Bellstedt, C., Gerardo Ezequiel Martín Carreño, Athanassiadis, A., Chaudhry, S.: URBAN CIRCULARITY ASSESSMENT METHOD (Deliverable 4.4 Metabolism of Cities). Technical report, Metabolism of Cities (Cityloops) (2022)

Towa, E., Zeller, V., Merciai, S., Schmidt, J., Achten, W.M.J.: Toward the development of subnational hybrid input-output tables in a multiregional framework. Journal of Industrial Ecology 26(1), 88–106 (2022). https://doi.org/10.1111/JIEC.13085

Towa, E., Zeller, V., Achten, W.M.J.J.: Assessing the circularity of regions: stakes of trade of waste for treatment. J. Ind. Ecol. 25(4), 834–847 (2021). https://doi.org/10.1111/jiec.13106

Noll, D., Lauk, C., Haas, W., Singh, S.J., Petridis, P., Wiedenhofer, D.: The sociometabolic transition of a small Greek island: assessing stock dynamics, resource flows, and material circularity from 1929 to 2019. J. Ind. Ecol. 26(2), 577–591 (2022). https://doi.org/10.1111/JIEC.13206

Macarthur, E.: Circular Indicators: An approach to measuring circularity. Technical Report 1, Ellen MacArthur Foundation (2015). http://www.ellenmacarthurfoundation.org/circularity-indicators/

Brändström, J., Eriksson, O.: How circular is a value chain? Proposing a material efficiency metric to evaluate business models. J. Clean. Prod. 342, 130973 (2022). https://doi.org/10.1016/j.jclepro.2022.130973

Pulido Barrera, P., Rosales Carreón, J., de Boer, H.J.: A multi-level framework for metabolism in urban energy systems from an ecological perspective. Resour. Conserv. Recycl. 132, 230–238 (2018). https://doi.org/10.1016/J.RESCONREC.2017.05.005

Arbabi, H., Tan, L.M., Mayfield, M.: Comments on ‘A multi-level framework for metabolism in urban energy systems from an ecological perspective’ by Pulido Barrera et al. (2018). Resour. Conserv. Recycl. 136, 463–465 (2018). https://doi.org/10.1016/j.resconrec.2018.04.028

Council, European: Directive 2008/98/CE of the European Parliament and of the Council of 19 November 2008 on waste and repealing certain Directives. Off. J. Eur. Union L312, 1–59 (2008)

Cools, P., Oosterlynck, S.: De Kringwinkel: A symbiosis between jobs for the long term unemployed and waste reduction. Technical Report March, OaSeS - University of Antwerp, Antwerp (2015). http://improve-research.eu/?page_id=2507.com

Souza, V., Fröhling, M., Pigosso, D.: Modelling the Resource Circularity Gap with Preparation for Reuse Flows Using a Generic Material Flow Analysis Framework. In: WasteEng 2022, Copenhagen, Denmark (2022)

Tanzer, J., Rechberger, H.: Setting the common ground: a generic framework for material flow analysis of complex systems. Recycling 4(23), 1–28 (2019). https://doi.org/10.3390/recycling4020023

Peffers, K., Tuunanen, T., Rothenberger, M.A., Chatterjee, S.: A design science research methodology for information systems research. J. Manag. Inf. Syst. 24(3), 45–77 (2007). https://doi.org/10.2753/MIS0742-1222240302

de Souza, V., Bloemhof-Ruwaard, J.M., Borsato, M.: Towards regenerative supply networks: a design framework proposal. J. Clean. Prod. 221, 145–156 (2019). https://doi.org/10.1016/j.jclepro.2019.02.178

Eurostat.: NUTS - Nomenclature of territorial units for statistics. https://ec.europa.eu/eurostat/web/nuts/background Accessed 24 Aug 2022

Braziotis, C., Bourlakis, M., Rogers, H., Tannock, J.: Supply chains and supply networks: distinctions and overlaps. Supply Chain Manag. 18(6), 644–652 (2013). https://doi.org/10.1108/SCM-07-2012-0260

Gemeente Amsterdam: Monitor Circulaire Economie (2022). https://onderzoek.amsterdam.nl/interactief/monitor-circulaire-economie Accessed 06 Sept 2022

Mayer, A., Haas, W., Wiedenhofer, D., Krausmann, F., Nuss, P., Blengini, G.A.: Measuring progress towards a circular economy: a monitoring framework for economy-wide material loop closing in the EU28. J. Ind. Ecol. 23(1), 62–76 (2019). https://doi.org/10.1111/JIEC.12809

De Kringwinkel.: De Kringwinkel in cijfers (2019). https://www.dekringwinkel.be/de-kringwinkel-in-cijfers Accessed 24 Feb 2021

Eurostat.: Waste Treatment (2022). https://ec.europa.eu/eurostat/databrowser/view/ENV_WASTRT__custom_3239085/default/table?lang=en &category=cei.cei_srm Accessed 26 Aug 2022

Bianchi, M., Tapia, C., del Valle, I.: Monitoring domestic material consumption at lower territorial levels: a novel data downscaling method. J. Ind. Ecol. 24(5), 1074–1087 (2020). https://doi.org/10.1111/JIEC.13000

Zisopoulos, F.K., Teigiserova, D.A., Schraven, D., Jong, M.D., Tong, X.: Regenerative economics for a balanced transition towards a circular EU27 : Economies beyond the maximization of circularity (2022)

Vermeulen, W., Reike, D., Wities, S.: Solving confusion around new conceptions of circularity by synthesising and re-organising the 3R’s concept into a 10R hierarchy. Development Research Society (September) (2019)

Bellika, S.K.: Final report on European approaches to Urban Resource Centres available (2019). https://ec.europa.eu/futurium/en/circular-economy/final-report-european-approaches-urban-resource-centres-available.html Accessed 28 July 2022

REFLOW, Metabolic: Reflow Amsterdam - redesigning urban textile flows (2020). https://reflowproject.eu/blog/reflow-amsterdam-redesigning-urban-textile-flows/ Accessed 29 July 2022

Acknowledgements

This project received funding from EU’s Horizon 2020 research and innovation programme under the Marie Skłodowska-Curie grant agreement No 899987. The corresponding author also would like to acknowledge all the support given by the Universidade Federal Tecnológica do Paraná, Campus Cornélio Procópio.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Funding

Open Access funding enabled and organized by Projekt DEAL. This project received funding from the European Union’s Horizon 2020 research and innovation programme under the Marie Skłodowska-Curie grant agreement No 899987. The corresponding author also would like to acknowledge all the support given by the Universidade Federal Tecnológica do Paraná, Campus Cornélio Procópio.

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Authors’ contributions

All authors have contributed equally for writing this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A: List of Variables and Acronyms

Variable/Acronym | Description |

|---|---|

\(\alpha \) (EoL-to-OMU) | ratio of end of life material (waste) from overall material used |

\(\beta \) (TRT-to-EoL) | ratio of treated waste from EoL material |

CG | Circularity Gap |

CE | Circular Economy |

CMU | Circular Material Use Rate |

CRO | Community Reuse Organisation |

d | index for DESTATIS estimates |

DE | Domestic Extraction |

DESTATIS | Federal Statistical Office of Germany |

DMC | Domestic Material Consumption |

DMI | Direct Material Inputs |

e | index for Eurostat estimates |

EoL | End-of-Life |

\(\epsilon \) | recovery rate upper bound |

EU | European Union |

EU27 | European Union 27 member states aggregate |

Eurostat | European Statistical Office |

EUCEMF | European Union’s Circular Economy Monitoring Framework |

EXP | Material Exports |

\(EXP_W\) | Waste Exports |

\(\gamma \) (RCV-to-TRT) | ratio of recovered waste from treated waste |

GDP | Gross Domestic Product |

IMP | Material Imports |

\(IMP_W\) | Waste Imports |

LCR | Local Circularity Rate |

OMU | Overall Material Used |

MCI | Material Circularity Indicator |

MFA | Material Flow Analysis |

\(NCG_c\) | National Circularity Gap |

NUTS | Nomenclature of territorial units for statistics |

PfR | Preparation for Reuse |

PM | Processed Materials |

RCN | Resource Circularity Network |

RCV | Recovered Waste (no backfilling) |

SD | Sankey diagram |

SM | Secondary Materials |

TRT | Waste Processed |

WTB | Waste Trade Balance |

Appendix B: Symbols for input, intermediate and output flows within the RCN and between the RCN and the environment.

Symbol (\(x_{j,l}, \forall x \in X_k\)) | Source | Destination |

|---|---|---|

\(i_{2,1}\) | Consumer | 2nd Life Retailing (3rd) |

\(i_{2,2}\) | Retailing | 2nd Life Retailing (3rd) |

\(i_{2,3}\) | Product manufacturing | 2nd Life Retailing (3rd) |

\(i_{2,4}\) | Component Production | 2nd Life Retailing (3rd) |

\(i_{2,5}\) | Material Production | 2nd Life Retailing (3rd) |

\(i_{3,1}\) | Consumer | Repair |

\(i_{4,1}\) | Product Manufacturing | Refurbishing |

\(i_{4,2}\) | Component Production | Refurbishing |

\(i_{5,1}\) | Product Manufacturing | Remanufacturing |

\(i_{5,2}\) | Component Production | Remanufacturing |

\(i_{7,1}\) | Material Production | Recycling |

\(i_{J,1}\) | Consumer | Collection |

\(i_{J,2}\) | Material Production | Collection |

\(i_{J,3}\) | Component Production | Collection |

\(i_{J,4}\) | Product Manufacturing | Collection |

\(i_{J,5}\) | Retailing | Collection |

\(i_{J,6}\) | Landfill | Cannibalisation |

\(i_{J,7}\) | Consumer | URC |

\(q_{2,1}\) | URC | 2nd Life Retailing |

\(q_{2,2}\) | Refurbishing | 2nd Life Retailing (3rd) |

\(q_{2,3}\) | Repairing | 2nd Life Retailing (3rd) |

\(q_{3,1}\) | URC | Repairing |

\(q_{4,1}\) | URC | Refurbishing |

\(q_{5,1}\) | URC | Remanufacturing |

\(q_{6,1}\) | URC | Repurposing |

\(q_{7,1}\) | URC | Recycling |

\(q_{7,2}\) | Cannibalisation | Recycling |

\(q_{9,0}\) | Collection | Cannibalisation |

\(q_{J,0}\) | Collection | URC |

\(q_{J,2}\) | Cannibalisation | URC |

\(o_{2,1}\) | URC | Consumer |

\(o_{2,2}\) | 3rd-party Repurposing | Retailer |

\(o_{2,3}\) | 3rd-party Refurbishing | Retailer |

\(o_{2,4}\) | 3rd-party 2nd Life Retailing | Consumer |

\(o_{2,5}\) | 3rd-party Repairing | Retailer |

\(o_{2,6}\) | Cannibalisation | Low developed Country |

\(o_{2,7}\) | 3rd-party Remanufacturing | Retailer |

\(o_{7,0}\) | Collection | Low developed Country |

\(o_{7,2}\) | Recycler | Material Producer |

\(o_{8,0}\) | Collection | Incineration |

\(o_{8,1}\) | URC | Incineration |

\(o_{10,0}\) | Collection | Landfill |

Appendix C: EU Sankey Material Flow Diagram

Appendix D: Circular Economy 3.0 Framework

The “Circular Economy 3.0” Framework. Source: [47]

Appendix E: Urban Resource Centre

An illustration of the concept of Urban Resource Centres. Source: [48]

Appendix F: Amsterdam Textiles SD

SD for the Reflow project used as a case of application for the RCN and LCR models. Slightly modified from [49]

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

de Souza, V.M., Fröhling, M. & Pigosso, D.C.A. A Multi-level Resource Circularity Index based in the European Union’s Circular Economy Monitoring Framework. Waste Biomass Valor 15, 615–636 (2024). https://doi.org/10.1007/s12649-023-02193-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-023-02193-6