Abstract

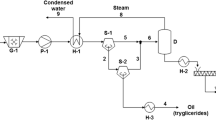

This work evaluated the extraction, refinement, characterization and economic analysis for producing oil rich in ɷ-3 from catfish processing wastes. All the unit operations of the extraction and refining processes were presented and the oil characterization were performed. The fatty acid profile of refined catfish oil presented, on average, fractions of 32%, 34% and 28% of the total saturated, monounsaturated and polyunsaturated fatty acids, respectively. Regards economical aspects, the estimated net present value was positive and indicated economic feasibility for all three processing waste capacity (20, 40 and 60 tons/year). The plant with the highest capacity recorded the best profitability. In this case, the net present value of US$ 764,934.62, the internal rate of return of 102.5% the earnings before interest and taxes of US$ 309,936.83/year, the return on sales of 53.18% and the profit after tax of US$ 263,446.31/year showed that the production of oil using catfish wastes is economically attractive. The minimum length of time necessary to recover the capital investment ranged from 1.56 to 2.76 years. Sensitivity analysis showed that the net present value of cash flow after tax remains positive until the price of oil reaches a threshold value of US$ 108.80/kg (20 tons/year), US$ 96.94/kg (40 tons/year) and US$ 79.65/kg (60 tons/year).

Graphic Abstract

Similar content being viewed by others

References

FAO: The State of World Fisheries and Aquaculture 2018 - Meeting the sustainable development goals. Rome. Licence: CC BY-NC-SA 3.0 IGO (2018)

WPRFMC: Western Pacific Regional Fishery Management Council. Fish Processing Waste: A Valuable Co-Product of the Fishing Industry, Honolulu (2010)

FAO: Food and Agriculture Organization of the United Nations. The State of World Fisheries and Aquaculture 2020. Sustainability in action, Rome. https://doi.org/10.4060/ca9229en (2020)

Lehn, D.N., Esquerdo, V.M., Dahlem Júnior, M.A., Dall’Agnol, W., dos Santos, A.C.F., de Souza, C.F.V., Pinto, L.A.A.: Microencapsulation of different oils rich in unsaturated fatty acids using dairy industry waste. J. Clean. Prod. 196, 665–673 (2018). https://doi.org/10.1016/j.jclepro.2018.06.127

Silva, J.F.X., Ribeiro, K., Silva, J.F., Cahú, T.B., Bezerra, R.S.: Utilization of tilapia processing waste for the production of fish protein hydrolysate. Anim. Feed Sci. Technol. 196, 96–106 (2014). https://doi.org/10.1016/j.anifeedsci.2014.06.010

Angulo, B., Fraile, J.M., Gil, L., Herrerías, C.I.: Bio-lubricants production from fish oil residue by transesterification with trimethylolpropane. J. Clean. Prod. 202, 81–87 (2018). https://doi.org/10.1016/j.jclepro.2018.07.260

Engelmann, J.I., Silva, P.P., Igansi, A.V., Pohndorf, R.S., Cadaval, T.R.S., Crexi, V.T., Pinto, L.A.A.: Structured lipids by swine lard interesterification with oil and esters from common carp viscera. J. Food Process Eng. 41, 1–9 (2018). https://doi.org/10.1111/jfpe.12679

Jayathilakan, K., Sultana, K., Radhakrishna, K., Bawa, A.S.: Utilization of byproducts and waste materials from meat, poultry and fish processing industries: a review. J. Food Sci. Technol. 49, 278–293 (2012). https://doi.org/10.1007/s13197-011-0290-7

Joumard-Cubizolles, L., Lee, J.C.Y., Vigor, C., Leung, H.H., Bertrand-Michel, J., Galano, J.M., Mazur, A., Durand, T., Gladine, C.: Insight into the contribution of isoprostanoids to the health effects of omega 3 PUFAs. Prostaglandins Other Lipid Mediat. 133, 111–122 (2017). https://doi.org/10.1016/j.prostaglandins.2017.05.005

Punia, S., Sandhu, K.S., Siroha, A.K., Dhull, S.B.: Omega 3-metabolism, absorption, bioavailability and health benefits–a review. PharmaNutrition 10, 100162 (2019). https://doi.org/10.1016/j.phanu.2019.100162

Igansi, A.V., Engelmann, J., Lütke, S.F., Porto, F.B., Pinto, L.A.A., Cadaval, T.R.S.: Isotherms, kinetics, and thermodynamic studies for adsorption of pigments and oxidation products in oil bleaching from catfish waste. Chem. Eng. Commun. 206, 1410–1424 (2019). https://doi.org/10.1080/00986445.2018.1539965

Rubio-Rodríguez, N., Beltrán, S., Jaime, I., de Diego, S.M., Sanz, M.T., Carballido, J.R.: Production of omega-3 polyunsaturated fatty acid concentrates: a review. Innov. Food Sci. Emerg. Technol. 11(1), 1–12 (2010). https://doi.org/10.1016/j.ifset.2009.10.006

Crexi, V.T., Monte, M.L., Monte, M.L., Pinto, L.A.A.: Polyunsaturated fatty acid concentrates of carp oil: chemical hydrolysis and urea complexation. J. Am. Oil Chem. Soc. 89, 329–334 (2012)

AOAC: Association of Official Analytical Chemists. Official methods of analysis of A.O.A.C. International, 16 edn. Arlington, USA (1995)

Bligh, E.G., Dyer, W.J.: A rapid method of total lipid extractionand purification. Can. J. Biochem. Physiol. 37(8), 911–917 (1959)

Crexi, V.T., Monte, M.L., Soares, L.A.S., Pinto, L.A.A.: Production and refinement of oil from carp (Cyprinus carpio) viscera. Food Chem. 119, 945–950 (2010). https://doi.org/10.1016/j.foodchem.2009.07.050

AOCS: Official and Tentative Methods of the American Oil Chemist’s Society, 7rd ed. American Oil Chemist’s Society Press, Urbana (2001)

Felder, R.M., Rousseau, R.W., Bullard, L.G.: Elementary Principles of Chemical Processes, 4th edn. Wiley, Hoboken (2015)

Moraes, P.S., Engelmann, J.I., Igansi, A.V., Cadaval, T.R.S., Pinto, L.A.A.: Nile tilapia industrialization waste: evaluation of the yield, quality and cost of the biodiesel production process. J. Clean. Prod. 287, 125041 (2021). https://doi.org/10.1016/j.jclepro.2020.125041

Peters, M.S., Timmerhaus, K.D., West, R.E.: Plant Design and Economics for Chemical Engineers. Mc Graw Hill, New York (2003)

Kaliba, A.R., Engle, C.R., Bouras, D.: Economic analysis of producing fishmeal and fish oil from channel catfish, Ictalurus punctatus, processing wastes. J. World Aquac. Soc. 41, 49–60 (2010). https://doi.org/10.1111/j.1749-7345.2009.00312.x

Couper, J.R.: Process Engineering Economics. Marcel Dekker, New York (2003)

Brown, T.: Engineering, Economics and Economic Design for Process Engineers. CRC Press Chemical Engineering, 2010. Economic indicators. http://www.che-digital.com (2007). Accessed 18 Mar 2021

Remer, D.S., Nieto, A.P.: A compendium and comparison of 25 project evaluation techniques Part 1: net present value and rate of return methods. Int. J. Prod. Econ. 42(42), 79–96 (1995)

Remer, D.S., Nieto, A.P.: A compendium and comparison of 25 project evaluation techniques. Part 2: Ratio, payback, and accounting methods. Int. J. Prod. Econ. 42, 101–129 (1995)

Mota, F.A.S., Costa-Filho, J.T., Barreto, G.A.: The Nile tilapia viscera oil extraction for biodiesel production in Brazil: an economic analysis. Renew. Sustain. Energy Rev. 108, 1–10 (2019). https://doi.org/10.1016/j.rser.2019.03.035

Belli, P., Anderson, J.R., Barnum, H.N., Dixon, J.A., Tan, J.: Economic Analysis of Investment Operations: Analytical Tools and Practical Applications. WBI Development Studies, Washington, D.C (2001)

Martin, J.: Management Accounting Concepts, Techniques and Controversial Issues, Chapter 11. Conventional Linear Cost-Volume-Profit Analysis. https://maaw.info/Chapter11.htm (2006). Accessed 18 Mar 2021

Moraes, P.S., Engelmann, J.I., Igansi, A.V., Cadaval, T.R.S., Pinto, L.A.A.: Nile tilapia industrialization waste: evaluation of the yield, quality and cost of the biodiesel production process. J. Cleaner Production. 287, 125041 (2021). https://doi.org/10.1016/j.jclepro.2020.125041

Engelmann, J.I., Silva, P.P., Igansi, A.V., Monte, M.L., Pohndorf, R.S., Cadaval, T.R.S., Crexi, V.T., Pinto, L.A.A.: Structured lipids of swine lard and oils from byproducts of skipjack tuna and of common carp. J. Food Process. Preserv. 45(2), e15154 (2020). https://doi.org/10.1111/jfpp.15154

FAO: Food and Agriculture Organization of the United Nations. Codex Alimentarius Commission. 42nd Session, Gevena: Switzerland (2019)

Acknowledgements

The authors would like to thank the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES)/Brazil–Finance Code 001 and the Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq)/Brazil for the financial support. The authors also would like to thank the projects DCIT 70/2015 and DCIT 77/2016 of the Secretaria de Desenvolvimento, Ciência e Tecnologia/RS/Brazil for the financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Igansi, A.V., da Silva, P.P., Engelmann, J.I. et al. Techno-Economic Analysis of Producing Oil Rich in ɷ-3 from Catfish Processing Wastes. Waste Biomass Valor 13, 707–717 (2022). https://doi.org/10.1007/s12649-021-01502-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-021-01502-1