Abstract

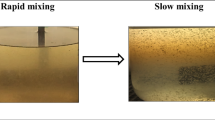

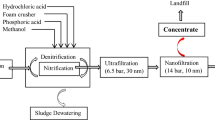

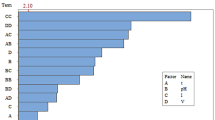

Electroforced sedimentation (EFS) is a well-known technique for enhancing the solid content of the final sludge cake. However, the parameters affecting the performance of EFS and quality of the resulting sludge cake, as well as the removed water, are not sufficiently studied. In this research, a mixture of zinc oxide (representing sludge) and polyacrylamide (dewatering aid) were used as experimental materials. The process parameters of electroforced sedimentation were optimized using a design of experiment software (Design Expert ® Version 7.0.0) with a face-centered central composite design (FCCCD) under response surface methodology. An optimization study was carried out for the output response (sedimentation velocity) based on three process factors and an empirical model was developed. The optimized values for current density, total solid volume per unit cross-sectional area and polyacrylamide dose for the highest sedimentation velocity (0.0199 cm/min) were 6.0 A/m2, 7.74 mm and 1.53 % (based on the weight of zinc oxide), respectively. The overall model was significant with Prob > F value of 0.0117 and R 2 value of 0.8911 while the most significant parameter was observed to be the current density with a Prob > F value of 0.0004. Validation experiments were conducted to confirm and measure the accuracy of the models for the three set of parameters including optimum parameters. The error was within the limit of prediction accuracy, and the sedimentation velocity was enhanced by the addition of 1.53 % PAM as dewatering aid. Thus, it was concluded that EFS can be applied successfully for materials having permanent charge.

Similar content being viewed by others

References

Brisolara, K.F., Qi, Y.: Biosolids and sludge management. Water Environ. Res. 87(10), 1147–1166 (2015)

Rose, K.P., Farenhorst, A., Claeys, A., Ascef, B.: 17 β-estradiol and 17 α-ethinylestradiol mineralization in sewage sludge and biosolids. J. Environ. Sci. Health, Part B 49(11), 871–879 (2014)

Raynaud, M., Vaxelaire, J., Olivier, J., Dieude-Fauvel, E., Baudez, J.-C.: Compression dewatering of municipal activated sludge: effects of salt and pH. Water Res. 46(14), 4448–4456 (2012)

Vijh, A.K.: Electrochemical aspects of electroosmotic dewatering of clay suspensions. Dry. Technol. 13(1–2), 215–224 (1995)

Jami, M.S., Iwata, M.: Effect of operating parameters on the effectiveness of electric field-enhanced separations. Dry. Technol. 26(8), 1068–1078 (2008). doi:10.1080/07373930802179392

Jami, M.S., Iwata, M., Muyibi, S.A., Karim, M.I.A., Al-Khatib, M.A.F.R., Mustapha, M.: Enhanced electroforced sedimentation of various solid–liquid systems. Afr. J. Biotechnol. 10(81), 18906–18909 (2013)

Jami, M.S., Iwata, M.: A new method for the theoretical analysis of electroforced sedimentation using Terzaghi–Voigt combined model. Sep. Sci. Technol. 43(5), 979–995 (2008)

Shirato, M., Murase, T., Tokunaga, A., Yamada, O.: Calculations of consolidation period in expression operations. J. Chem. Eng. Jpn. 7(3), 229–231 (1974)

Iwata, M.: Electroosmotic Dewatering. In: Tsuda, T. (ed.) Electric Field Applications in Chromatography, Industrial and Chemical Processes, pp. 133–151. VCH, Weinheim (1995)

Iwata, M., Igami, H., Murase, T., Yoshida, H.: Combined operation of electroosmotic dewatering and mechanical expression. J. Chem. Eng. Jpn. 24(3), 399–401 (1991)

Tuan, P.-A., Mika, S., Pirjo, I.: Sewage sludge electro-dewatering treatment—a review. Dry. Technol. 30(7), 691–706 (2012)

Besra, L., Sengupta, D., Roy, S., Ay, P.: Influence of surfactants on flocculation and dewatering of kaolin suspensions by cationic polyacrylamide (PAM-C) flocculant. Sep. Purif. Technol. 30(3), 251–264 (2003)

Jami, M.S., Rosli, N.-S., Amosa, M.K.: Optimization of manganese reduction in biotreated POME onto 3A molecular sieve and clinoptilolite zeolites. Water Environ. Res. (2015). doi:10.2175/106143015X14362865227157

Montgomery, D.C.: Design and Analysis of Experiments, 5th edn. Wiley, New York (2004)

Turan, N.G., Ozgonenel, O.: The design and implementation of adsorptive removal of Cu(II) from leachate using ANFIS. Sci. World J. 2013, 590267 (2013)

Muralidhar, R., Chirumamila, R., Marchant, R., Nigam, P.: A response surface approach for the comparison of lipase production by Candida cylindracea using two different carbon sources. Biochem. Eng. J. 9(1), 17–23 (2001)

Chang, G., Liu, J., Lee, D.: Co-conditioning and dewatering of chemical sludge and waste activated sludge. Water Res. 35(3), 786–794 (2001)

Boráň, J., Houdková, L., Elsäßer, T.: Processing of sewage sludge: dependence of sludge dewatering efficiency on amount of flocculant. Resour. Conserv. Recycl. 54(5), 278–282 (2010)

Lu, L., Pan, Z., Hao, N., Peng, W.: A novel acrylamide-free flocculant and its application for sludge dewatering. Water Res. 57, 304–312 (2014)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Alam, M.M., Alam, M.Z., Jami, M.S. et al. Study of the Effects of Process Parameters on Electroforced Sedimentation in Solid–Liquid Separation Using Response Surface Methodology. Waste Biomass Valor 7, 583–591 (2016). https://doi.org/10.1007/s12649-015-9469-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-015-9469-x