Abstract

Solidification structure is a key aspect for understanding the mechanical performance of metal alloys, wherein composition and casting parameters considerably influence solidification and determine the unique microstructure of the alloys. By following the principle of free energy minimization, the phase-field method eliminates the need for tracking the solid/liquid phase interface and has greatly accelerated the research and development efforts geared toward optimizing metal solidification microstructures. The recent progress in the application of phase-field simulation to investigate the effect of alloy composition and casting process parameters on the solidification structure of metals is summarized in this review. The effects of several typical elements and process parameters, including carbon, boron, silicon, cooling rate, pulling speed, scanning speed, anisotropy, and gravity, on the solidification structure are discussed. The present work also addresses the future prospects of phase-field simulation and aims to facilitate the widespread applications of phase-field approaches in the simulation of microstructures during solidification.

Similar content being viewed by others

References

L.Y. Zhang, Y.H. Jiang, Z. Ma, et al., Effect of cooling rate on solidified microstructure and mechanical properties of aluminium-A356 alloy, J. Mater. Process. Technol., 207(2008), No. 1–3, p. 107.

P. Köhnen, S. Ewald, J.H. Schleifenbaum, A. Belyakov, and C. Haase, Controlling microstructure and mechanical properties of additively manufactured high-strength steels by tailored solidification, 35(2020), art. No. 101389.

H.T. Zheng, R.R. Chen, G. Qin, et al., Microstructure evolution, Cu segregation and tensile properties of CoCrFeNiCu high entropy alloy during directional solidification, J. Mater. Sci. Technol., 38(2020), p. 19.

S. Roy, S. Suwas, S. Tamirisakandala, D.B. Miracle, and R. Srinivasan, Development of solidification microstructure in boron-modified alloy Ti–6Al–4V–0.1B, Acta Mater., 59(2011), No. 14, p. 5494.

M. Ali Jaafar, D.R. Rousse, S. Gibout, and J.P. Bédécarrats, A review of dendritic growth during solidification: Mathematical modeling and numerical simulations, Renewable Sustainable Energy Rev., 74(2017), p. 1064.

F.Y. Wang, L.S. Dong, H.H. Wu, et al., Enhanced nanocrystalline stability of BCC iron via copper segregation, Prog. Nat. Sci., 33(2023), No. 2, p. 185.

H. Assadi, A phase-field model for non-equilibrium solidification of intermetallics, Acta Mater., 55(2007), No. 15, p. 5225.

M.G. Mecozzi, J. Sietsma, S. van der Zwaag, M. Apel, P. Schaffnit, and I. Steinbach, Analysis of the γ → α transformation in a C-Mn steel by phase-field modeling, Metall. Mater. Trans. A, 36(2005), No. 9, p. 2327.

R.G. Thiessen and I.M. Richardson, A strategy for modeling microstructure in macroscopic simulations of welded material, Metall. Mater. Trans. B, 37(2006), No. 2, p. 293.

R.G. Thiessen and I.M. Richardson, A physically based model for microstructure development in a macroscopic heat-affected zone: Grain growth and recrystallization, Metall. Mater. Trans. B, 37(2006), No. 4, p. 655.

M.G. Mecozzi, J. Sietsma, and S. van der Zwaag, Analysis of γ → α transformation in a Nb micro-alloyed C-Mn steel by phase field modelling, Acta Mater., 54(2006), No. 5, p. 1431.

W.F. Rao and A.G. Khachaturyan, Phase field theory of proper displacive phase transformations: Structural anisotropy and directional flexibility, a vector model, and the transformation kinetics, Acta Mater., 59(2011), No. 11, p. 4494.

Y.Z. Wang and A.G. Khachaturyan, Multi-scale phase field approach to martensitic transformations, Mater. Sci. Eng. A, 438–440(2006), p. 55.

K.W. Lai, S.J. Shi, Z.W. Yan, et al., Phase-field simulation of re-dissolution of γ’ phase in Ni-Al alloy by continuous and second-order aging treatment, Rare Met., 40(2021), No. 5, p. 1155.

C. Yang, S.L. Li, X.T. Wang, J.S. Wang, and H.B. Huang, Phase-field simulation of multi-phase interactions in Fe-C peritectic solidification, Comput. Mater. Sci., 171(2020), art. No. 109220.

K. Dargahi Noubary, M. Kellner, P. Steinmetz, J. Hötzer, and B. Nestler, Phase-field study on the effects of process and material parameters on the tilt angle during directional solidification of ternary eutectics, Comput. Mater. Sci., 138(2017), p. 403.

I. Steinbach, Phase-field models in materials science, Modell. Simul. Mater. Sci. Eng., 17(2009), No. 7, art. No. 073001.

J. Eiken, B. Böttger, and I. Steinbach, Multiphase-field approach for multicomponent alloys with extrapolation scheme for numerical application, Phys. Rev. E, 73(2006), No. 6, art. No. 066122.

S.J. Lv, H.H. Wu, K.Y. Wang, et al., The microstructure evolution and influence factors of acicular ferrite in low alloy steels, Comput. Mater. Sci., 218(2023), art. No. 111989.

S.J. Lv, H.H. Wu, K.Y. Wang, et al., The austenite to polygonal ferrite transformation in low-alloy steel: Multi-phase-field simulation, J. Mater. Res. Technol., 24(2023), p. 9630.

I. Steinbach, F. Pezzolla, B. Nestler, et al., A phase field concept for multiphase systems, Physica D, 94(1996), No. 3, p. 135.

S. Fukumoto and S. Nomoto, Microstructure simulation for solidification of stainless steel by multi-phase-field model, J. Jpn. Inst. Met. Mater., 73(2009), No. 7, p. 502.

S.J. Lv, S.Z. Wang, G.L. Wu, et al., Application of phase-field modeling in solid-state phase transformation of steels, J. Iron Steel Res. Int., 29(2022), No. 6, p. 867.

S.G. Kim, W.T. Kim, J.S. Lee, M. Ode, and T. Suzuki, Large scale simulation of dendritic growth in pure undercooled melt by phase-field model, ISIJ Int., 39(1999), No. 4, p. 335.

W.J. Boettinger, J.A. Warren, C. Beckermann, and A. Karma, Phase-field simulation of solidification, Annu. Rev. Mater. Res., 32(2002), p. 163.

Y.X. Geng, H. Tang, J.H. Xu, et al., Influence of process parameters and aging treatment on the microstructure and mechanical properties of AlSi8Mg3 alloy fabricated by selective laser melting, Int. J. Miner. Metall. Mater., 29(2022), No. 9, p. 1770.

W.L. Wang, C. Lu, L.J. Zhou, and P.S. Lyu, Research methods and influencing factors of interfacial heat transfer during subrapid solidification process of strip casting, J. Iron Steel Res. Int., 29(2022), No. 1, p. 3.

C.F. Bai, B. Wang, J. Ma, J.Y. Zhang, and W.P. Pan, Modeling effect of cooling conditions on solidification process during thermal cycle of rollers in twin-roll strip casting, J. Iron Steel Res. Int., 30(2023), No. 1, p. 64.

E. Safary, R. Taghiabadi, and M.H. Ghoncheh, Mechanical properties of Al–15Mg2Si composites prepared under different solidification cooling rates, Int. J. Miner. Metall. Mater., 29(2022), No. 6, p. 1249.

J.Z. An, Z.Z. Cai, and M.Y. Zhu, Effect of titanium content on the refinement of coarse columnar austenite grains during the solidification of peritectic steel, Int. J. Miner. Metall. Mater., 29(2022), No. 12, p. 2172.

Y.G. Chabak, K. Shimizu, V.G. Efremenko, et al., Microstructure and phase elemental distribution in high-boron multi-component cast irons, Int. J. Miner. Metall. Mater., 29(2022), No. 1, p. 78.

T. He, R. Hu, J.R. Yang, and H.Z. Fu, Phase selection and solidification path transition of Ti–48Al–xNb alloys with different cooling rates, Rare Met., 42(2023), No. 1, p. 288.

H.Y. Zhang, Z.Y. Zhang, Y.F. Xu, et al., Microstructure and magnetocaloric properties of partially crystallized Gd60Co30Fe10 amorphous alloy prepared by different solidification cooling rates, Rare Met., 41(2022), No. 1, p. 246.

Z.S. Jin, F.Y. Cao, G.Y. Cao, et al., Effect of casting temperature on the solidification process and (micro)structure of Zr-based metallic glasses, J. Mater. Res. Technol., 22(2023), p. 3010.

B. Lu, Y. Li, H.Y. Wang, et al., Effects of cooling rates on the solidification behavior, microstructural evolution and mechanical properties of Al-Zn-MgCu alloys, J. Mater. Res. Technol., 22(2023), p. 2532.

K.H. Shi, K.C. Zhou, Z.Y. Li, X.Q. Zan, K.L. Dong, and Q. Jiang, Microstructure and properties of ultrafine WC–Co–VC cemented carbides with different Co contents, Rare Met., 41(2022), No. 6, p. 1955.

H.J. Fan, Y. Liu, J.W. Ye, W.B. Qiu, and Y.C. Qiu, Microstructure and mechanical properties of WC–(Ti, M)(C, N)–Co cemented carbides with different nitrogen contents, Rare Met., 41(2022), No. 10, p. 3530.

M.F. Qi, L.Y. Wei, Y.Z. Xu, et al., Effect of trace yttrium on the microstructure, mechanical property and corrosion behavior of homogenized Mg–2Zn–0.1Mn–0.3Ca–xY biological magnesium alloy, Int. J. Miner. Metall. Mater., 29(2022), No. 9, p. 1746.

A.V. Koltygin, V.E. Bazhenov, I.V. Plisetskaya, et al., Influence of Zr and Mn additions on microstructure and properties of Mg–2.5wt%Cu–Xwt%Zn (X = 2.5, 5 and 6.5) alloys, Int. J. Miner. Metall. Mater., 29(2022), No. 9, p. 1733.

S.H. Ma, H.Q. Hao, D. Wang, L.H. Lou, and J. Zhang, Effects of Ta on the solidification behavior and microstructure of a rhenium-containing hot corrosion resistant single crystal, Int. J. Miner. Metall. Mater., 26(2019), No. 7, p. 901.

H.L. Huang, Z.H. Jia, Y. Xing, X.L. Wang, and Q. Liu, Micro-structure of Al-Si-Mg alloy with Zr/Hf additions during solidification and solution treatment, Rare Met., 38(2019), No. 11, p. 1033.

X.Y. Zhao, R.R. Chen, Y. Yang, et al., Microstructure and mechanical properties of Ti43Al6Nb alloys with different zirconium contents, Rare Met., 42(2023), No. 6, p. 2047.

R.Z. Zhang, J.S. He, S.G. Xu, F.C. Zhang, and X.T. Wang, The roles of Ce and Mn on solidification behaviors and mechanical properties of 7Mo super austenitic stainless steel, J. Mater. Res. Technol., 22(2023), p. 1238.

J.W. Elmer, S.M. Allen, and T.W. Eagar, Microstructural development during solidification of stainless steel alloys, Metall. Trans. A, 20(1989), No. 10, p. 2117.

M.M. Chen, R.H. Shi, Z.Z. Liu, et al., Phase-field simulation of lack-of-fusion defect and grain growth during laser powder bed fusion of Inconel 718, Int. J. Miner. Metall. Mater., (2023). DOI: https://doi.org/10.1007/s12613-023-2664-z

W.L. Wang, L.K. Wang, and P.S. Lyu, Kinetics of austenite growth and bainite transformation during reheating and cooling treatments of high strength microalloyed steel produced by subrapid solidification, Int. J. Miner. Metall. Mater., 30(2023), No. 2, p. 354.

C. Wei, J. Wang, B.W. Dong, et al., Properties and microstructural evolution of a ternary Cu-Co-Fe immiscible alloy solidified under high magnetic fields, J. Mater. Res. Technol., 24(2023), p. 3564.

Y.J. Zhang, J.X. Zhou, Y.J. Yin, X.Y. Ji, X. Shen, and Z. Guo, Study on the solutal convection during dendrite growth of superalloy under directional solidification condition, J. Mater. Res. Technol., 23(2023), p. 3916.

C.L. Shang, H.H. Wu, G.F. Pan, et al., The characteristic microstructures and properties of steel-based alloy via additive manufacturing, Materials, 16(2023), No. 7, art. No. 2696.

M. Paju and R. Möller, The effect of boron on phosphorus segregation in austenite, Scripta Metall., 18(1984), No. 8, p. 813.

W. Chen, M.C. Chaturvedi, and N.L. Richards, Effect of boron segregation at grain boundaries on heat-affected zone cracking in wrought INCONEL 718, Metall. Mater. Trans. A, 32(2001), No. 4, p. 931.

J.G. Jung, J. Kim, K.M. Noh, K.K. Park, and Y.K. Lee, Effects of B on microstructure and hardenability of resistance seam welded HSLA linepipe steel, Sci. Technol. Weld. Join., 17(2012), No. 1, p. 77.

B.C. Yan, J. Zhang, and L.H. Lou, Effect of boron additions on the microstructure and transverse properties of a directionally solidified superalloy, Mater. Sci. Eng. A, 474(2008), No. 1–2, p. 39.

Q. Hu, L. Liu, X.B. Zhao, S.F. Gao, J. Zhang, and H.Z. Fu, Effect of carbon and boron additions on segregation behavior of directionally solidified nickel-base superalloys with rhenium, Trans. Nonferrous Met. Soc. China, 23(2013), No. 11, p. 3257.

H.S. Whitesell and R.A. Overfelt, Influence of solidification variables on the microstructure, macrosegregation, and porosity of directionally solidified Mar-M247, Mater. Sci. Eng. A, 318(2001), No. 1–2, p. 264.

H.W. Lee, Y.H. Kim, S.H. Lee, K.H. Lee, J.U. Park, and J.H. Sung, Effect of boron contents on weldability in high strength steel, J. Mech. Sci. Technol., 21(2007), No. 5, p. 771.

M. Amirthalingam, E.M. van der Aa, C. Kwakernaak, M.J.M. Hermans, and I.M. Richardson, Elemental segregation during resistance spot welding of boron containing advanced high strength steels, Weld. World, 59(2015), No. 5, p. 743.

H.S. Furtado, A.T. Bernardes, R.F. Machado, and C.A. Silva, Numerical simulation of solute trapping phenomena using phase-field solidification model for dilute binary alloys, Mat. Res., 12(2009), No. 3, p. 345.

H. Shibata, Y. Arai, M. Suzuki, and T. Emi, Kinetics of peritectic reaction and transformation in Fe-C alloys, Metall. Mater. Trans. B, 31(2000), No. 5, p. 981.

Y.K. Chuang, D. Reinisch, and K. Schwerdtfeger, Kinetics of the diffusion controlled peritectic reaction during solidification of iron–carbon-alloys, Metall. Trans. A, 6(1975), No. 1, p. 235.

Y.Z. Shen, J.H. Liu, and H. Xu, Study of peritectic phase transition in high-Mn steel using phase-field method, Metall. Mater. Trans. B, 53(2022), No. 1, p. 121.

M.G. Mendiratta, T.A. Parthasarathy, and D.M. Dimiduk, Oxidation behavior of αMo-Mo3Si-Mo5SiB2 (T2) three phase system, Intermetallics, 10(2002), No. 3, p. 225.

G. Hasemann, S. Ida, L. Zhu, T. Iizawa, K. Yoshimi, and M. Krüger, Experimental assessment of the microstructure evolution and liquidus projection in the Mo-rich Mo–Si–B system, Mater. Des., 185(2020), art. No. 108233.

R.A. Gaisin, V.M. Imayev, R.A. Shaimardanov, and R.M. Imayev, Structure and properties of Mo–9Si–8B alloy fabricated by casting, Inorg. Mater. Appl. Res., 8(2017), No. 5, p. 750.

J.A. Lemberg and R.O. Ritchie, Mo-Si-B alloys for ultrahigh-temperature structural applications, Adv. Mater., 24(2012), No. 26, p. 3445.

B. Nestler and A.A. Wheeler, Phase-field modeling of multiphase solidification, Comput. Phys. Commun., 147(2002), No. 1–2, p. 230.

J. Kundin, E. Pogorelov, and H. Emmerich, Phase-field modeling of the microstructure evolution and heterogeneous nucleation in solidifying ternary Al-Cu-Ni alloys, Acta Mater., 83(2015), p. 448.

O. Kazemi, G. Hasemann, M. Krüger, and T. Halle, Microstructure evolution and sequence of phase transition reactions through the solidification of Mo-Si-B alloy; a phase-field study, Comput. Mater. Sci., 193(2021), art. No. 110422.

D. Montiel, L. Liu, L. Xiao, Y. Zhou, and N. Provatas, Microstructure analysis of AZ31 magnesium alloy welds using phase-field models, Acta Mater., 60(2012), No. 16, p. 5925.

S. Gurevich, M. Amoorezaei, D. Montiel, and N. Provatas, Evolution of microstructural length scales during solidification of magnesium alloys, Acta Mater., 60(2012), No. 8, p. 3287.

Y.B. Wang, M.G. Wei, X.T. Liu, et al., Phase-field study of the effects of the multi-controlling parameters on columnar dendrite during directional solidification in hexagonal materials, Eur. Phys. J. E, 43(2020), No. 7, art. No. 41.

U. Scipioni Bertoli, B.E. MacDonald, and J.M. Schoenung, Stability of cellular microstructure in laser powder bed fusion of 316L stainless steel, Mater. Sci. Eng. A, 739(2019), p. 109.

I. Yadroitsev, P. Krakhmalev, I. Yadroitsava, S. Johansson, and I. Smurov, Energy input effect on morphology and microstructure of selective laser melting single track from metallic powder, J. Mater. Process. Technol., 213(2013), No. 4, p. 606.

L.F. Liu, Q.Q. Ding, Y. Zhong, et al., Dislocation network in additive manufactured steel breaks strength–ductility trade-off, Mater. Today, 21(2018), No. 4, p. 354.

T. Pinomaa, M. Lindroos, M. Walbrühl, N. Provatas, and A. Laukkanen, The significance of spatial length scales and solute segregation in strengthening rapid solidification microstructures of 316L stainless steel, Acta Mater., 184(2020), p. 1.

X.B. Gong and K. Chou, Phase-field modeling of microstructure evolution in electron beam additive manufacturing, JOM, 67(2015), No. 5, p. 1176.

S. Chu, C.W. Guo, T.X. Zhang, et al., Phase-field simulation of microstructure evolution in electron beam additive manufacturing, Eur. Phys. J. E, 43(2020), No. 6, art. No. 35.

L.M. Wu and J. Zhang, Phase field simulation of dendritic solidification of Ti–6Al–4V during additive manufacturing process, JOM, 70(2018), No. 10, p. 2392.

J. Zhang, L.M. Wu, Y. Zhang, and L.B. Meng, Phase field simulation of dendritic microstructure in additively manufactured titanium alloy, Met. Powder Rep., 74(2019), No. 1, p. 20.

S. Sahoo and K. Chou, Phase-field simulation of microstructure evolution of Ti–6Al–4V in electron beam additive manufacturing process, Addit. Manuf., 9(2016), p. 14.

F.Y. Yu, The influence of anisotropy on the evolution of interfacial morphologies in directional solidification: A phase-field study, arXiv e-prints, 2022. https://api.semanticscholar.org/CorpusID:253223918

W.A. Tiller, K.A. Jackson, J.W. Rutter, and B. Chalmers, The redistribution of solute atoms during the solidification of metals, Acta Metall., 1(1953), No. 4, p. 428.

W.W. Mullins and R.F. Sekerka, Stability of a planar interface during solidification of a dilute binary alloy, [in] Pierre Pelcé, ed., Dynamics of Curved Fronts, Elsevier, Amsterdam, 1988, p. 345.

J.A. Warren and J.S. Langer, Prediction of dendritic spacings in a directional-solidification experiment, Phys. Rev. E, 47(1993), No. 4, p. 2702.

M. Plapp, Phase-field modelling of solidification microstructures, J. Indian Inst. Sci., 96(2016), No. 3, p. 179.

A. Karma and W.J. Rappel, Phase-field method for computationally efficient modeling of solidification with arbitrary interface kinetics, Phys. Rev. E, 53(1996), No. 4, p. R3017.

A. Karma and W.J. Rappel, Quantitative phase-field modeling of dendritic growth in two and three dimensions, Phys. Rev. E, 57(1998), No. 4, p. 4323.

Z.J. Wang, J.C. Wang, and G.C. Yang, Onset of initial planar instability with surface-tension anisotropy during directional solidification, Phys. Rev. E, 80(2009), No. 5, art. No. 052603.

Z.B. Dong, W.J. Zheng, Y.H. Wei, and K.J. Song, Dynamic evolution of initial instability during non-steady-state growth, Phys. Rev. E, 89(2014), No. 6, art. No. 062403.

F.Y. Yu, Y.Z. Ji, Y.H. Wei, and L.Q. Chen, Effect of the misorientation angle and anisotropy strength on the initial planar instability dynamics during solidification in a molten pool, Int. J. Heat Mass Transf., 130(2019), p. 204.

S. Jana, J. Jakumeit, R. Tiefers, and T. Stoyanov, Simulation of cold shuts and misruns in centrifugal casting of TiAl low pressure turbine blades, Mater. Sci. Forum, 765(2013), p. 155.

M. Cisternas Fernández, M. Založnik, H. Combeau, and U. Hecht, Thermosolutal convection and macrosegregation during directional solidification of TiAl alloys in centrifugal casting, Int. J. Heat Mass Transf., 154(2020), art. No. 119698.

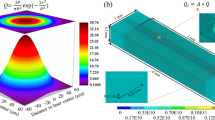

A. Viardin, J. Zollinger, L. Sturz, et al., Columnar dendritic solidification of TiAl under diffusive and hypergravity conditions investigated by phase-field simulations, Comput. Mater. Sci., 172(2020), art. No. 109358.

H.J. Diepers and I. Steinbach, Interaction of interdendritic convection and dendritic primary spacing: Phase-field simulation and analytical modeling, Mater. Sci. Forum, 508(2006), p. 145.

I. Steinbach, Pattern formation in constrained dendritic growth with solutal buoyancy, Acta Mater., 57(2009), No. 9, p. 2640.

M. Apel, H.J. Diepers, and I. Steinbach, On the effect of interdendritic flow on primary dendrite spacing: A phase field study and analytical scaling relations, [in] C.A. Gandin, ed., Modeling of Casting, Welding and Advanced Solidification Processes XI, Opio, Vol. 1, 2006, p. 505.

C.C. Battalle, R.N. Grugel, A.B. Hmelo, and T.G. Wang, The effect of enhanced gravity levels on microstructural development in Pb-50 wt pct Sn alloys during controlled directional solidification, Metall. Mater. Trans. A, 25(1994), No. 4, p. 865.

A. Viardin, Y. Souhar, M. Cisternas Fernández, M. Apel, and M. Založnik, Mesoscopic modeling of equiaxed and columnar solidification microstructures under forced flow and buoyancy-driven flow in hypergravity: Envelope versus phase-field model, Acta Mater., 199(2020), p. 680.

Acknowledgements

The present work is financially supported by the National Key Research and Development Program of China (No. 2021YFB3702401) and the National Natural Science Foundation of China (Nos. 51901013, 52122408, and 52071023). H.H. Wu also thanks the financial support from the Fundamental Research Funds for the Central Universities, China (University of Science and Technology Beijing (USTB), Nos. FRF-TP-2021-04C1 and 06500135). The computing work is supported by USTB MatCom of Beijing Advanced Innovation Center for Materials Genome Engineering. J.M. Zhu thanks the financial support from the Qilu Young Talent Program of Shandong University, Zhejiang Lab Open Research Project, China (No. K2022PE0AB05), the Shandong Provincial Natural Science Foundation, China (No. ZR2023MA058), and the Guangdong Basic and Applied Basic Research Foundation, China (No. 2023A1515011819).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Xinping Mao and Honghui Wu are an advisory board member and a youth editorial board member for this journal, respectively, and they were not involved in the editorial review or the decision to publish this article. All authors confirm that they have no competing interests or financial ties that could influence the outcomes or interpretation of this research.

Rights and permissions

About this article

Cite this article

Wang, K., Lv, S., Wu, H. et al. Recent research progress on the phase-field model of microstructural evolution during metal solidification. Int J Miner Metall Mater 30, 2095–2111 (2023). https://doi.org/10.1007/s12613-023-2710-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-023-2710-x