Abstract

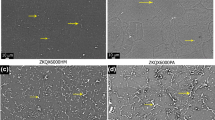

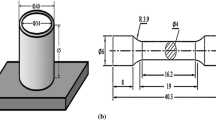

This work studied the effects of adding Zr and Mn in amounts less than 1wt% on the microstructure, mechanical properties, casting properties, and corrosion resistance of Mg—Zn—Cu alloys containing 2.5wt% Cu and 2.5wt%—6.5wt% Zn. The hardness and electrical conductivity measurements were used to find an optimal heat treatment schedule with the best mechanical properties. It has been established that Zr significantly increases the yield strength of the alloys due to a strong grain refinement effect. However, the presence of Mn and Zr has a detrimental effect on alloy’s elongation at fracture. It was shown that the precipitation of the Mg2Cu cathodic phase in the alloy structure negatively affects the corrosion behavior. Nevertheless, the addition of Mn decreases the corrosion rate of the investigated alloys. The best combination of the mechanical, casting, and corrosion properties were achieved in the alloys containing 2.5wt% Cu and 5wt% Zn. However, the Mn or Zr addition can improve the properties of the alloys; for example, the addition of Mn or Zr increases the fluidity of the alloys.

Similar content being viewed by others

References

K.U. Kainer, Magnesium Alloys and Their Applications, Wiley-VCH Verlag GmbH, Weinheim, 2000.

A.A. Luo, Magnesium casting technology for structural applications, J. Magnes. Alloys, 1(2013), No. 1, p. 2.

H.C. Pan, Y.P. Ren, H. Fu, H. Zhao, L.Q. Wang, X.Y. Meng, and G.W. Qin, Recent developments in rare-earth free wrought magnesium alloys having high strength: A review, J. Alloys Compd., 663(2016), p. 321.

S.H. You, Y.D. Huang, K.U. Kainer, and N. Hort, Recent research and developments on wrought magnesium alloys, J. Magnes. Alloys, 5(2017), No. 3, p. 239.

H. Yu, Y.M. Kim, B.S. You, H.S. Yu, and S.H. Park, Effects of cerium addition on the microstructure, mechanical properties and hot workability of ZK60 alloy, Mater. Sci. Eng. A, 559(2013), p. 798.

X.H. Chen, L.Z. Liu, F.S. Pan, J.J. Mao, X.Y. Xu, and T. Yan, Microstructure, electromagnetic shielding effectiveness and mechanical properties of Mg-Zn-Cu-Zr alloys, Mater. Sci. Eng. B, 197(2015), p. 67.

Y. Zhang, X.F. Huang, Y. Ma, T.J. Chen, Y.D. Li, and Y. Hao, Effects of Cu addition on microstructure and mechanical properties of as-cast Mg-6Zn magnesium alloy, China Foundry, 14(2017), No. 4, p. 251.

B.L. Mordike and T. Ebert, Magnesium: Properties—applications—potential, Mater. Sci. Eng. A, 302(2001), No. 1, p. 37.

J. Buha, Mechanical properties of naturally aged Mg-Zn-Cu-Mn alloy, Mater. Sci. Eng. A, 489(2008), No. 1–2, p. 127.

L.G. Xu, X.X. Li, J. Ye, X. Ji, H. Qiu, J. Luo, and H.G. Yang, Thermodynamic optimization design of casting Mg-Zn-Cu alloy, Adv. Mater. Res., 852(2014), p. 183.

I.J. Polmear, Light Alloys: From Traditional Alloys to Nanocrystals, 4th ed., Butterworth-Heinemann, Oxford, 2005.

M.M. Avedesian and H. Baker, Magnesium and Magnesium Alloys, ASM Specialty Handbook, ASM International, Materials Park, OH, 1999.

Y.W. Song, E.H. Han, D.Y. Shan, C.D. Yim, and B.S. You, The effect of Zn concentration on the corrosion behavior of Mg—xZn alloys, Corros. Sci., 65(2012), p. 322.

C. Liu, X.K. Fu, H.B. Pan, P. Wan, L. Wang, L.L. Tan, K.H. Wang, Y. Zhao, K. Yang, and P.K. Chu, Biodegradable Mg-Cu alloys with enhanced osteogenesis, angiogenesis, and long-lasting antibacterial effects, Sci. Rep., 6(2016), art. No. 27374.

G.L. Makar and J. Kruger, Corrosion of magnesium, Int. Mater. Rev., 38(1993), No. 3, p. 138.

G.L. Song, Control of biodegradation of biocompatable magnesium alloys, Corros. Sci., 49(2007), No. 4, p. 1696.

O. Lunder, T.K. Aune, and K. Nisancioglu, Effect of Mn additions on the corrosion behavior of mould-cast magnesium ASTM AZ91, Corrosion, 43(1987), No. 5, p. 291.

K. Gusieva, C.H.J. Davies, J.R. Scully, and N. Birbilis, Corrosion of magnesium alloys: The role of alloying, Int. Mater. Rev., 60(2015), No. 3, p. 169.

H.M. Zhu, C.P. Luo, J.W. Liu, and D.L. Jiao, Effects of Cu addition on microstructure and mechanical properties of as-cast magnesium alloy ZK60, Trans. Nonferrous Met. Soc. China, 24(2014), No. 3, p. 605.

D.S. Gandel, M.A. Easton, M.A. Gibson, T. Abbott, and N. Birbilis, The influence of zirconium additions on the corrosion of magnesium, Corros. Sci., 81(2014), p. 27.

J.O. Andersson, T. Helander, L. Höglund, P.F. Shi, and B. Sundman, Thermo-Calc & DICTRA, computational tools for materials science, Calphad, 26(2002), No. 2, p. 273.

Thermo-Calc Software, TCMG4 Magnesium Alloys Databases Version 4, Thermo-Calc Software, Stockholm [2020-01-10]. https://thermocalc.com/products/databases/magnesium-based-alloys/

A.V. Koltygin, V.E. Bazhenov, N.V. Letyagin, and V.D. Belov, The influence of composition and heat treatment on the phase composition and mechanical properties of ML19 magnesium alloy, Russ. J. Non-Ferrous Met., 59(2018), No. 1, p. 32.

V.E. Bazhenov, A.V. Petrova, and A.V. Koltygin, Simulation of fluidity and misrun prediction for the casting of 356.0 aluminum alloy into sand molds, Int. J. Metalcast., 12(2018), No. 3, p. 514.

A.V. Koltygin, V.E. Bazhenov, E.A. Belova, and A.A. Nikitina, Development of a magnesium alloy with good casting characteristics on the basis of Mg-Al-Ca-Mn system, having Mg-Al2Ca structure, J. Magnes. Alloys, 1(2013), No. 3, p. 224.

ASTM International, ASTM Standard G102–89: Standard Practice for Calculation of Corrosion Rates and Related Information from Electrochemical Measurements, ASTM International, West Conshohocken, 2015.

M. Qian, D.H. StJohn, and M.T. Frost, Characteristic zirconium-rich coring structures in Mg-Zr alloys, Scripta Mater., 46(2002), No. 9, p. 649.

L. Yang, X.R. Zhou, M. Curioni, S. Pawar, H. Liu, Z.Y. Fan, G. Scamans, and G. Thompson, Corrosion behavior of pure magnesium with low iron content in 3.5 wt% NaCl solution, J. Electrochem. Soc., 162(2015), No. 7, p. C362.

J. Gjønnes and C.J. Simensen, An electron microscope investigation of the microstructure in an aluminium-zinc-magnesium alloy, Acta Metall., 18(1970), No. 8, p. 881.

G.A. Song, J.S. Lee, J.S. Park, N.S. Lee, W.H. Lee, and K.B. Kim, Mechanical properties of large-scale Mg-Cu-Zn ultrafine eutectic composites, J. Alloys Compd., 481(2009), No. 1–2, p. 135.

J. Buha and T. Ohkubo, Natural aging in Mg-Zn(-Cu) alloys, Metall. Mater. Trans. A, 39(2008), No. 9, p. 2259.

J.D. Robson, D.T. Henry, and B. Davis, Particle effects on recrystallization in magnesium-manganese alloys: Particle pinning, Mater. Sci. Eng. A, 528(2011), No. 12, p. 4239.

G.S. Peng, Y. Wang, and Z. Fan, Competitive heterogeneous nucleation between Zr and MgO particles in commercial purity magnesium, Metall. Mater. Trans. A, 49(2018), No. 6, p. 2182.

V.E. Bazhenov, A.V. Koltygin, M.C. Sung, S.H. Park, Y.V. Tselovalnik, A.A. Stepashkin, A.A. Rizhsky, M.V. Belov, V.D. Belov, and K.V. Malyutin, Development of Mg-Zn-Y-Zr casting magnesium alloy with high thermal conductivity, J. Magnes. Alloys, 9(2021), No. 5, p. 1567.

ASM Handbook Committee, Properties and Selection: Nonferrous Alloys and Special-Purpose Materials, ASM Handbook, Vol. 2, ASM International, Materials Park, OH, 1990.

M. Qian and A. Das, Grain refinement of magnesium alloys by zirconium: Formation of equiaxed grains, Scripta Mater., 54(2006), No. 5, p. 881.

D. Vinotha, K. Raghukandan, U.T.S. Pillai, and B.C. Pai, Grain refining mechanisms in magnesium alloys—An overview, Trans. Indian Inst. Met., 62(2009), No. 6, p. 521.

Y.C. Lee, A.K. Dahle, and D.H. StJohn, The role of solute in grain refinement of magnesium, Metall. Mater. Trans. A, 31(2000), No. 11, p. 2895.

D.J. Lloyd and S.A. Court, Influence of grain size on tensile properties of Al-Mg alloys, Mater. Sci. Technol., 19(2003), No. 10, p. 1349.

A.K. Dahle, P.A. Tøndel, C.J. Paradies, and L. Arnberg, Effect of grain refinement on the fluidity of two commercial Al-Si foundry alloys, Metall. Mater. Trans. A, 27(1996), No. 8, p. 2305.

K.R. Ravi, R.M. Pillai, K.R. Amaranathan, B.C. Pai, and M. Chakraborty, Fluidity of aluminum alloys and composites: A review, J. Alloys Compd., 456(2008), No. 1–2, p. 201.

H.X. Li, S.K. Qin, Y.Z. Ma, J. Wang, Y.J. Liu, and J.S. Zhang, Effects of Zn content on the microstructure and the mechanical and corrosion properties of as-cast low-alloyed Mg-Zn-Ca alloys, Int. J. Miner. Metall. Mater., 25(2018), No. 7, p. 800.

P.J. Wang, L.W. Ma, X.Q. Cheng, and X.G. Li, Influence of grain refinement on the corrosion behavior of metallic materials: A review, Int. J. Miner. Metall. Mater., 28(2021), No. 7, p. 1112.

Acknowledgements

The authors gratefully acknowledge financial support form the Ministry of Science and Higher Education of the Russian Federation in the framework of MegaGrant (No. 220-7868-7477).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors report no potential conflict of interest.

Rights and permissions

About this article

Cite this article

Koltygin, A.V., Bazhenov, V.E., Plisetskaya, I.V. et al. Influence of Zr and Mn additions on microstructure and properties of Mg—2.5wt%Cu—Xwt%Zn (X = 2.5, 5 and 6.5) alloys. Int J Miner Metall Mater 29, 1733–1745 (2022). https://doi.org/10.1007/s12613-021-2369-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-021-2369-0