Abstract

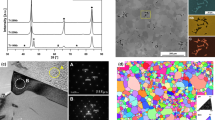

This study determined the optimal concentration of titanium diboride (TiB2) particles for the development of in situ titanium–titanium boride (Ti–TiB) metal matrix composites (MMCs) prepared by a conventional powder metallurgy route to be used for industrial applications. The effect of concentration of TiB2 particles was studied by reinforcing TiB2 powder in different mass fractions (2wt%, 5wt%, 10wt%, and 20wt%) into pure Ti powder during the fabrication process. The MMCs were sintered at high temperatures under vacuum. The transmission electron microscopy (TEM) results revealed the formation of needle-shaped TiB whiskers, indicating that in situ reaction occurred during vacuum sintering of the powder compacts. All the composite samples had a high sintered density, and the hardness of the composites increased with an increase in the mass fraction of reinforcement. Mechanical and tribological properties such as flexural strength, impact, and wear properties were determined and found to be dependent on the mass fraction of the reinforcement. However, the mechanism for the in situ reaction needs further investigation by high-energy in situ X-ray diffraction techniques.

Similar content being viewed by others

References

K.K. Chawla, Metal Matrix Composites, R.W. Cahn, P. Haasen and E.J. Kramer, eds., Willey and Sons, 2006.

K.K. Chawla, Composite Materials: Science and Engineering, Springer, 2012.

M.D. Hayat, H. Singh, Z. He, and P. Cao, Titanium metal matrix composites: An overview, Composites Part A, 121(2019), p. 418.

Y. Enomoto and T. Yamamoto, New materials in automotive tribology, Tribol. Lett., 5(1998), No. 1, p. 13.

J.E. Allison and G.S. Cole, Metal-matrix composites in the automotive industry: Opportunities and challenges, JOM, 45(1993), No. 1, p. 19.

P.R. Smith and F.H. Froes, Developments in titanium metal matrix composites, JOM, 36(1984), No. 3, p. 19.

C.M. Ward-Close, M.R. Winstone, and P.G. Partridge, Developments in the processing of titanium alloy metal matrix composites, Mater. Des., 15(1994), No. 2, p. 67.

I.A. Ibrahim, F.A. Mohamed and E. J. Lavernia, Particulate reinforced metal matrix composites—a review, J. Mater. Sci., 26(1991), No. 5, p. 1137.

K. Geng, W.J. Lu, Y.X. Qin, and D. Zhang, In situ preparation of titanium matrix composites reinforced with TiB whiskers and Y2O3 particles, Mater. Res. Bull., 39(2004), No. 6, p. 873.

L. Geng, D.R. Ni, J. Zhang, and Z.Z. Zheng, Hybrid effect of TiBw and TiCp on tensile properties of in situ titanium matrix composites, J. Alloys Compd., 463(2008), No. 1–2, p. 488.

T.M.T. Godfrey, P.S. Goodwin, and C.M. Ward-Close, Production of titanium particulate metal matrix composite by mechanical milling, Mater. Sci. Technol., 16(2000), No. 7–8, p. 753.

S.F. Li, K. Kondoh, H. Imai, B. Chen, L. Jia, J. Umeda, and Y.B. Fu, Strengthening behavior of in situ-synthesized (TiC–TiB)/Ti composites by powder metallurgy and hot extrusion, Mater. Des., 95(2016), p. 127.

Z.H. Zhang, X.B. Shen, F.C. Wang, and S.K. Lee, A new rapid route for in situ synthesizing monolithic TiB ceramic, J. Am. Ceram. Soc., 94(2011), No. 9, p. 2754.

D.X. Li, D.H. Ping, Y.X. Lu, and H.Q. Ye, Characterization of the microstructure in TiB-whisker reinforced Ti alloy matrix composite, Mater. Lett., 16(1993), No. 6, p. 322.

W.O. Soboyejo, R.J. Lederich, and S.M.L. Sastry, Mechanical behavior of damage tolerant TiB whisker-reinforced in situ titanium matrix composites, Acta Metall. Mater., 42(1994), No. 8, p. 2579.

M. Zadra and L. Girardini, High-performance, low-cost titanium metal matrix composites, Mater. Sci. Eng. A, 608(2014), p. 155.

A.K. Gangopadhyay and J.L. Margrave, Thermodynamic properties of inorganic substances. VI. The high temperature heat contents of chromel-P and alumel, J. Chem. Eng. Data, 8(1963), No. 2, p. 204.

K.B. Panda and K.S. Ravi Chandran, Synthesis of ductile titanium–titanium boride (Ti–TiB) composites with a beta- titanium matrix: The nature of TiB formation and composite properties, Metall. Mater. Trans. A, 34(2003), No. 6, p. 1371.

H. Attar, M. Bönisch, M. Calin, L.C. Zhang, S. Scudino, and J. Eckert, Selective laser melting of in situ titanium–titanium boride composites: Processing, microstructure and mechanical properties, Acta Mater., 76(2014), p. 13.

T.M.T. Godfrey, A. Wisbey, P.S. Goodwin, K. Bagnall, and C.M. Ward-Close, Microstructure and tensile properties of mechanically alloyed Ti–6A1–4V with boron additions, Mater. Sci. Eng. A, 282(2000), No. 1–2, p. 240.

C.J. Zhang, J.P. Qu, J. Wu, S.Z. Zhang, J.C. Han, M.D. Hayat, and P. Cao, A titanium composite with dual reinforcements of micrometer sized TiB and submicrometer sized Y2O3, Mater. Lett., 233(2018), p. 242.

J.C. Han, Z.D. Lü, C.J. Zhang, S.Z. Zhang, H.Z. Zhang, P. Lin, and P. Cao, The microstructural characterization and mechanical properties of 5 vol.% (TiBw + TiCp)/Ti composite produced by open-die forging, Metals, 8(2018), No. 7, p. 485.

M.Y. Koo, J.S. Park, M.K. Park, K.T. Kim, and S.H. Hong, Effect of aspect ratios of in situ formed TiB whiskers on the mechanical properties of TiBw/Ti–6Al–4V composites, Scripta Mater., 66(2012), No. 7, p. 487.

M. De Graef, J.P.A. Löfvander, C. McCullough, and C.G. Levi, The evolution of metastable Bf borides in a TiAlB alloy, Acta Metall. Mater., 40(1992), No. 12, p. 3395.

T. Lundström, Transition metal borides, [in] V.I. Matkovich, G.V. Samsonov, P. Hagenmuller, and T. Lundstrom, eds., Boron and Refractory Borides, Springer-Verlag Berlin Heidelberg, 1977, p. 351.

Z. Fan, Z.X. Guo, and B. Cantor, The kinetics and mechanism of interfacial reaction in sigma fibre-reinforced Ti MMCs, Composites Part A, 28(1997), No. 2, p. 131.

I.Y. Kim, B.J. Choi, Y.J. Kim, and Y.Z. Lee, Friction and wear behavior of titanium matrix (TiB + TiC) composites, Wear, 271(2011), No. 9–10, p. 1962.

M. Selva Kumar, P. Chandrasekar, P. Chandramohan, and M. Mohanraj, Characterisation of titanium–titanium boride composites processed by powder metallurgy techniques, Mater. Charact., 73(2012), p. 43.

J.Y. Zhang, W.X. Ke, W. Ji, Z. Fan, W.M. Wang, and Z.Y. Fu, Microstructure and properties of in situ titanium boride (TiB)/titanium (TI) composites, Mater. Sci. Eng. A, 648(2015), p. 158.

H.B. Feng, D.C. Jia, and Y. Zhou, Spark plasma sintering reaction synthesized TiB reinforced titanium matrix composites, Composites Part A, 36(2005), No. 5, p. 558.

J.S. Kim, K.M. Lee, D.H. Cho, and Y.Z. Lee, Fretting wear characteristics of titanium matrix composites reinforced by titanium boride and titanium carbide particulates, Wear, 301(2013), No. 1–2, p. 562.

N. Kang, P. Coddet, Q. Liu, H.L. Liao, and C. Coddet, In-situ TiB/near a Ti matrix composites manufactured by selective laser melting, Addit. Manuf., 11(2016), p. 1.

K. Khanlari, M. Ramezani, P. Kelly, P. Cao, and T. Neitzert, Reciprocating sliding wear behavior of 60NiTi as compared to 440C steel under lubricated and unlubricated conditions, Tribol. Trans., 61(2018), p. 1.

Acknowledgements

The first author would like to thank the University of Auckland for providing a doctoral scholarship. The author would like to thank Prof. A.W.H. Ngan for providing an opportunity to work at the University of Hong Kong, China. The author also acknowledges the Electron Microscope Unit (EMU) of the University of Hong Kong, China. This work was partially supported by the Titanium Technologies New Zealand (TiTeNZ) Programme funded by the Ministry of Business Innovation and Employment (MBIE), New Zealand.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Singh, H., Hayat, M., Zhang, H. et al. Effect of TiB2 content on microstructure and properties of in situ Ti-TiB composites. Int J Miner Metall Mater 26, 915–924 (2019). https://doi.org/10.1007/s12613-019-1797-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-019-1797-6