Abstract

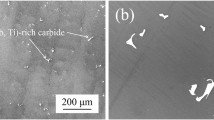

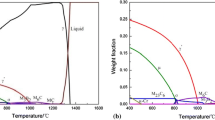

The effect of cooling rate during quenching on the microstructure and creep property of nickel-based superalloy FGH96 was investigated. Three groups of samples were quenched continuously with three fixed cooling rates, respectively, then subjected to a creep test under a constant load of 690 MPa at 700°C. Clear differences in size of secondary γ′ precipitates, creep properties and substructure of creep-tested samples were observed. The quantitative relationship among cooling rate, the size of secondary γ′ precipitates, and steady creep rate was constructed. It was found that with increasing cooling rate, the size of secondary γ′ precipitates decreases gradually, showing that the relationship between the size of secondary γ′ precipitates and the cooling rate obeys a power law, with an exponent of about −0.6, and the creep rate of steady state follows a good parabola relationship with cooling γ′ precipitate size. For 235°C/min, FGH96 alloy exhibited very small steady creep rate. The density of dislocation was low, and the isolated stacking fault was the dominant deformation mechanism. With decreasing cooling rates, the density of dislocation increased remarkably, and deformation microtwinning was the dominant deformation process. Detailed mechanisms for different cooling rate were discussed.

Similar content being viewed by others

References

M.J. Zhang, F.G. Li, S.Y. Wang, and C.Y. Liu, Effect of powder preparation technology on the hot deformation behavior of HIPed P/M nickel-based superalloy FGH96, Mater. Sci. Eng. A, 528(2011), No. 12, p. 4030.

Y.L. Gu, Y.H. He, S.Y. Qu, G.D. Zhang, F. Zheng, and C.H. Tao, Thermo-mechanical fatigue behavior of nickel-base powder metallurgy superalloy FGH96 under tension-tension loading, Acta Metall. Sin., 23(2010), No. 2, p. 147.

J. Mao, K.M. Chang, W.H. Yang, K. Ray, S.P. Vaze, and D.U. Ferrer, Cooling precipitation and strengthening study in powder metallurgy superalloy U720LI, Metall. Mater. Trans. A, 32(2001), No. 10, p. 2441.

S.G. Tian, J. Xie, X.M. Zhou, B.J. Qian, J.W. Lun, L.L. Yu, and W.X. Wang, Creep behaviors and influence factors of FGH95 Ni-base superalloy, Rare. Met. Mater. Eng., 40(2011), No. 5, p. 807.

Z.C. Peng, G.F. Tian, J. Jiang, M.Z. Li, Y. Chen, J.W. Zou, and F.P.E. Dunne, Mechanistic behaviour and modelling of creep in powder metallurgy FGH96 nickel superalloy, Mater. Sci. Eng. A, 676(2016), p. 441.

G.R. Leverant and B.H. Kear, The mechanism of creep in gamma prime precipitation-hardened nickel-base alloys at intermediate temperatures, Metall. Mater. Trans. B, 1(1970), No. 2, p. 491.

W.W. Milligan and S.D. Antolovich, Yielding and deformation behavior of the single crystal superalloy PWA 1480, Metall. Trans. A, 18(1987), No. 1, p. 85.

A. Manonukul, F.P.E. Dunne, and D. Knowles, Physically-based model for creep in Ni-base superalloy C263 both above and below the gama solvus, Acta Mater., 50(2002), No. 11, p. 2917.

P. Caron, P.J. Henderson, T. Khan, and M. McLean, On the effects of heat treatments on the creep behaviour of a single crystal superalloy, Scripta Metall., 20(1986), No. 6, p. 875.

Y.F. Feng, X.M. Zhou, J.W. Zou, X.F. Wang, G.F. Tian, and W.X. Wang, Effect of solution treatment temperature on the grain growth behavior of fine grained FGH96 superalloy, Mater. Sci. Forum, 898(2017), p. 446.

J. Mao, Gamma Prime Precipitation Modeling and Strength Responses in Powder Metallurgy Superalloys [Dissertation], West Virginia University, Morgantown, 2002, p. 86.

P.R. Bhowal, E.F. Wright, and E.L. Raymond, Effects of cooling rate and γ′ morphology on creep and stress-rupture properties of a powder metallurgy superalloy, Metall. Trans. A, 21(1990), No. 6, p. 1709.

P. Zhang, Y. Yuan, H. Yin, Y. Gu, J. Wang, M. Yang, G. Yang, and X. Song, Tensile properties and deformation mechanisms of Haynes 282 at various temperatures, Metall. Mater. Trans. A, 49(2018), No. 5, p. 1571.

F. Sun, Y.F. Gu, J.B. Yan, Z.H. Zhong, and M. Yuyama, Tensile deformation-induced dislocation configurations at intermediate temperatures in a Ni-Fe-based superalloy for advanced ultra-supercritical coal-fired power plants, J. Alloys Compd., 657(2016), p. 565.

M. Condat and B. Décamps, Shearing of γ′ precipitates by single a/2<110> matrix dislocations in a γ/γ′ Ni-based superalloy, Scripta Metall., 21(1987), No. 5, p. 607.

G.B. Viswanathan, P. Sarosi, M. Henry, D. Whitis, and M. Mills, Deformation mechanisms at intermediate creep temperatures in Rene 88DT, Mater. Sci. Eng. A, 400–401(2005), p. 489.

Q.Z. Chen and D.M. Knowles, Mechanism of <112>/3 slip initiation and anisotropy of γ′ phase in CMSX-4 during creep at 750°C and 750 MPa, Mater. Sci. Eng. A, 356(2003), No. 1–2, p. 352.

Acknowlegement

This work was financially supported by the National Material Special Program of China (No. JPPT-F2008-5-1).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Feng, Yf., Zhou, Xm., Zou, Jw. et al. Effect of cooling rate during quenching on the microstructure and creep property of nickel-based superalloy FGH96. Int J Miner Metall Mater 26, 493–499 (2019). https://doi.org/10.1007/s12613-019-1756-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-019-1756-2