Abstract

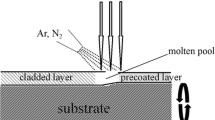

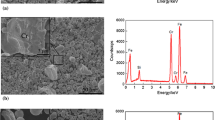

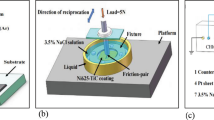

The wear and corrosion resistance of Fe72.2Cr16.8Ni7.3Mo1.6Mn0.7C0.2Si1.2 and Fe77.3Cr15.8Ni3.9Mo1.1Mn0.5C0.2Si1.2 coatings laser-cladded on AISI 4130 steel were studied. The coatings possess excellent wear and corrosion resistance despite the absence of expensive yttrium, tungsten, and cobalt and very little molybdenum. The microstructure mainly consists of dendrites and eutectic phases, such as duplex (γ+α)-Fe and the Fe–Cr (Ni) solid solution, confirmed via energy dispersive spectrometry and X-ray diffraction. The cladded Fe-based coatings have lower coefficients of friction, and narrower and shallower wear tracks than the substrate without the cladding, and the main wear mechanism is mild abrasive wear. Electrochemical test results suggest that the soft Fe72.2Cr16.8Ni7.3Mo1.6Mn0.7C0.2Si1.2 coating with high Cr and Ni concentrations has high passivation resistance, low corrosion current, and positive corrosion potential, providing a better protective barrier layer to the AISI 4130 steel against corrosion.

Similar content being viewed by others

References

G.M. Martínez-Cazares, A. Almanza, E. Almanza, and D.E. Lozano, Enhanced hardenability and tempering resistance of AISI 4130 steel by Ni addition, Mater. Perform. Charact., 5(2016), No. 1, p. 202.

I. Danaee, M.N. Khomami, and A.A. Attar, Corrosion behavior of AISI 4130 steel alloy in ethylene glycol-water mixture in presence of molybdate, Mater. Chem. Phys., 135(2012), No. 2-3, p. 658.

N. Hutasoit, V. Luzin, A. Blicblau, W. Yan, M. Brandt, and R. Cottam, Fatigue life of laser clad hardfacing alloys on AISI 4130 steel under rotary bending fatigue test, Int. J. Fatigue, 72(2015), p. 42.

S. Katakam, S. Santhanakrishnan, and N.B. Dahotre, Fe-based amorphous coatings on AISI 4130 structural steel for corrosion resistance, JOM, 64(2012), No. 6, p. 709.

M.R. Fernández, A. García, J.M. Cuetos, R. González, A. Noriega, and M. Cadenas, Effect of actual WC content on the reciprocating wear of a laser cladding NiCrBSi alloy reinforced with WC, Wear, 324-325(2015), p. 80.

T.E. Abioye, D.G. McCartney, and A.T. Clare, Laser cladding of inconel 625 wire for corrosion protection, J. Mater. Process. Technol., 217(2015), p. 232.

D. Bartkowski, A. Młynarczak, A. Piasecki, B. Dudziak, M. Gościański, and A. Bartkowska, Microstructure, microhardness and corrosion resistance of Stellite-6 coatings reinforced with WC particles using laser cladding, Opt. Laser Technol., 68(2015), p. 191.

Q.H. Li, M.M. Savalani, Q.M. Zhang, and L. Huo, High temperature wear characteristics of TiC composite coatings formed by laser cladding with CNT additives, Surf. Coat. Technol., 239(2014), p. 206.

J. Pereira, J. Zambrano, M. Licausi, and V. Amigó, Tribology and high temperature friction wear behavior of MCrAlY laser cladding coatings on stainless steel, Wear, 330-331(2015), p. 280.

A. Kusmoko, D.P. Dunne, and H.J. Li, A comparative study for wear resistant of Stellite 6 coatings on nickel alloy substrate produced by laser cladding, HVOF and plasma spraying techniques, Int. J. Curr. Eng. Technol., 4(2014), No. 1, p. 32.

P. Xu, C.X. Lin, C.Y. Zhou, and X.P. Yi, Wear and corrosion resistance of laser cladding AISI 304 stainless steel/Al2O3 composite coatings, Surf. Coat. Technol., 238(2014), p. 9.

J. Farmer, J.S. Choi, C. Saw, J. Haslam, D. Day, P. Hailey, and T.G. Lian, Iron-based amorphous metals: high-performance corrosion-resistant material development, Metall. Mater. Trans. A, 40(2009), No. 6, p. 1289.

R.Q. Guo, C. Zhang, Y. Yang, Y. Peng, and L. Liu, Corrosion and wear resistance of a Fe-based amorphous coating in underground environment, Intermetallics, 30(2012), p. 94.

S. Katakam, V. Kumar, S. Santhanakrishnan, R. Rajamure, P. Samimi, and N.B. Dahotre, Laser assisted Fe-based bulk amorphous coating: Thermal effects and corrosion, J. Alloys Compd., 604(2014), p. 266.

W.H. Liu, F.S. Shieu, and W.T. Hsiao, Enhancement of wear and corrosion resistance of iron-based hard coatings deposited by high-velocity oxygen fuel (HVOF) thermal spraying, Surf. Coat. Technol., 249(2014), p. 24.

Z.B. Zheng, Y.G. Zheng, W.H. Sun, and J.Q. Wang, Effect of applied potential on passivation and erosion-corrosion of a Fe-based amorphous metallic coating under slurry impingement, Corros. Sci., 82(2014), p. 115.

M. Yasir, C. Zhang, W. Wang, P. Xu, and L. Liu, Wear behaviors of Fe-based amorphous composite coatings reinforced by Al2O3 particles in air and in NaCl solution, Mater. Des., 88(2015), p. 207.

W. Wang, C. Zhang, P. Xu, M. Yasir, and L. Liu, Enhancement of oxidation and wear resistance of Fe-based amorphous coatings by surface modification of feedstock powders, Mater. Des., 73(2015), p. 35.

C. Zhang, R.Q. Guo, Y. Yang, Y. Wu, and L. Liu, Influence of the size of spraying powders on the microstructure and corrosion resistance of Fe-based amorphous coating, Electrochim. Acta, 56(2011), No. 18, p. 6380.

C. Zhang, L. Liu, K.C. Chan, Q. Chen, and C.Y. Tang, Wear behavior of HVOF-sprayed Fe-based amorphous coatings, Intermetallics, 29(2012), p. 80.

D. Zois, A. Lekatou, M. Vardavoulias, M., T. Vaimakis, and A.E. Karantzalis, Partially amorphous stainless steel coatings: Microstructure, annealing behavior and statistical optimization of spray parameters, Surf. Coat. Technol., 206(2011), No. 6, p. 1469.

M. Oksa, S. Tuurna, and T. Varis, Increased lifetime for biomass and waste to energy power plant boilers with HVOF coatings: high temperature corrosion testing under chlorine-containing molten salt, J. Therm. Spray Technol., 22(2013), No. 5, p. 783.

K. Chokethawai, D.G. McCartney, and P.H. Shipway, Microstructure evolution and thermal stability of an Fe-based amorphous alloy powder and thermally sprayed coatings, J. Alloys Compd., 480(2009), No. 2, p. 351.

Y.Z. Lv, Y.F. Sun, J.Y. Zhao, G.G. Yu, J.J. Shen, and S.M. Hu, Effect of tungsten on microstructure and properties of high chromium cast iron, Mater. Des., 39(2012), p. 303.

C. Scandian, C. Boher, J.D.B. de Mello, and F. Rézaï-Aria, Effect of molybdenum and chromium contents in sliding wear of high-chromium white cast iron: The relationship between microstructure and wear, Wear, 267(2009), No. 1-4, p. 401.

Z.P. Lu, C.T. Liu, and W.D. Porter, Role of yttrium in glass formation of Fe-based bulk metallic glasses, Appl. Phys. Lett., 83(2003), No. 13, p. 2581.

Z.K. Fu, H.H. Ding, W.J. Wang, Q.Y. Liu, J. Guo, and M.H. Zhu, Investigation on microstructure and wear characteristic of laser cladding Fe-based alloy on wheel/rail materials, Wear, 330-331(2015), p. 592.

S.F. Zhou, X.Q. Dai, and H.Z. Zheng, Microstructure and wear resistance of Fe-based WC coating by multi-track overlapping laser induction hybrid rapid cladding, Opt. Laser Technol., 44(2012), No. 1, p. 190.

C. Guo, J.S. Zhou, J.M. Chen, J. Zhao, Y.J. Yu, and H.D. Zhou, High temperature wear resistance of laser cladding NiCrBSi and NiCrBSi/WC–Ni composite coatings, Wear, 270(2011), No. 7-8, p. 492.

C.W. Yao, J. Huang, P.L. Zhang, Z.G. Li, and Y.X. Wu, Toughening of Fe-based laser-clad alloy coating, Appl. Surf. Sci., 257(2011), No. 6, p. 2184.

B.R. Kumar, S. Sharma, P. Munda, and R.K. Minz, Structure and microstructure evolution of a ternary Fe–Cr–Ni alloy akin to super martensitic stainless steel, Mater. Des., 50(2013), p. 392.

H. Zhang, Y. Zou, Z.D. Zou, and D.T. Wu, Microstructure and properties of Fe-based composite coating by laser cladding Fe–Ti–V–Cr–C–CeO2 powder, Opt. Laser Technol., 65(2015), p. 119.

V. Ocelik, D. Matthews, and J.T.M. De Hosson, Sliding wear resistance of metal matrix composite layers prepared by high power laser, Surf. Coat. Technol., 197(2005), No. 2-3, p. 303.

R. Chotěborský, P. Hrabě, M. Müller, J. Savková, and M. Jirka, Abrasive wear of high chromium Fe–Cr–C hardfacing alloys, Res. Agric. Eng., 54(2008), No. 4, p. 192.

J.F. Archard, Surface topography and tribology, Tribology, 7(1974), No. 5, p. 213.

X.L. Lu, X.B. Liu, P.C. Yu, Y.J. Zhai, S.J. Qiao, M.D. Wang, Y.G. Wang, and Y. Chen, Effects of heat treatment on microstructure and mechanical properties of Ni60/h-BN self-lubricating anti-wear composite coatings on 304 stainless steel by laser cladding, Appl. Surf. Sci., 355(2015), p. 350.

M.Y. Li, Y. Wang, B. Han, W.M. Zhao, and T. Han, Microstructure and properties of high chrome steel roller after laser surface melting, Appl. Surf. Sci., 255(2015), No. 17, p. 7574.

C. Navas, R. Colaço, J. de Damborenea, and R. Vilar, Abrasive wear behaviour of laser clad and flame sprayed-melted NiCrBSi coatings, Surf. Coat. Technol., 200(2006), No. 24, p. 6854.

A. Davoodi, M. Pakshir, M. Babaiee, and G.R. Ebrahimi, A comparative H2S corrosion study of 304L and 316L stainless steels in acidic media, Corros. Sci., 53(2011), No. 1, p. 399.

Y.L. Zhou, J. Chen, Y. Xu, and Z.Y. Liu, Effects of Cr, Ni and Cu on the corrosion behavior of low carbon microalloying steel in a Cl–containing environment, J. Mater. Sci. Technol., 29(2013), No. 2, p. 168.

M.W. Tan, E. Akiyama, H. Habazaki, A. Kawashima, K. Asami, and K. Hashimoto, The role of chromium and molybdenum in passivation of amorphous Fe–Cr–Mo–P–C alloys in deaerated 1 M HCl, Corros. Sci., 38(1996), No. 12, p. 2137.

Acknowledgements

This work was financially supported by the Ocean Public Science and Technology Research Fund Projects of China (No. 201405013-3), the Science & Technology Program of Shanghai Maritime University (No. 20130448), the China Postdoctoral Science Foundation (No. 2017M620153), and the National Natural Science Foundation of China (No. 51609133).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fan, L., Chen, Hy., Dong, Yh. et al. Wear and corrosion resistance of laser-cladded Fe-based composite coatings on AISI 4130 steel. Int J Miner Metall Mater 25, 716–728 (2018). https://doi.org/10.1007/s12613-018-1619-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-018-1619-2