Abstract

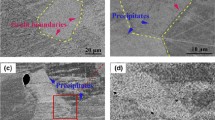

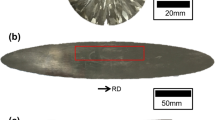

For strip steel with the thickness of 1.6 mm, the yield and tensile strengths as high as 760 and 850 MPa, respectively, were achieved using the compact strip production technology. Precipitates in the steel were characterized by scanning and transmission electron microscopy to elucidate the strengthening mechanism. In addition, intragranular misorientation, Kernel average misorientation, and stored energy were measured using electron backscatter diffraction for crystallographic analysis of ferrite grains containing precipitates and their neighbors without precipitates. It is found that precipitates in specimens primarily consist of TiC and Ti4C2S2. Ferrite grains containing precipitates exhibit the high Taylor factor as well as the crystallographic orientations with {012}, {011}, {112}, or {221} plane parallel to the rolling plane. Compared with the intragranular orientation of adjoining grains, the intragranular misorientation of grains containing precipitates fluctuates more frequently and more mildly as a function of distance. Moreover, the precipitates can induce ferrite grains to store a relatively large amount of energy. These results suggest that a correlation exists between precipitation in ferrite grains and grain crystallographic properties.

Similar content being viewed by others

References

S. Zaefferer, J. Ohlert, and W. Bleck, A study of microstructure, transformation mechanisms and correlation between microstructure and mechanical properties of a low alloyed TRIP steel, Acta Mater., 52(2004), No. 9, p. 2765.

K.D. Ralston, N. Birbilis, M. Weyland, and C.R. Hutchinson, The effect of precipitate size on the yield strength-pitting corrosion correlation in Al-Cu-Mg alloys, Acta Mater., 58(2010), No. 18, p. 5941.

C.Y. Chen, H.W. Yen, F.H. Kao, W.C. Li, C.Y. Huang, J.R. Yang, and S.H. Wang, Precipitation hardening of high-strength low-alloy steels by nanometer-sized carbides, Mater. Sci. Eng. A, 499(2009), No. 1–2, p. 162.

C.L. Davis and M. Strangwood, Preliminary study of the inhomogeneous precipitate distributions in Nb-microalloyed plate steels, J. Mater. Sci., 37(2002), No. 6, p. 1083.

J.F. Nie, Effects of precipitate shape and orientation on dispersion strengthening in magnesium alloys, Scripta Mater., 48(2003), No. 8, p. 1009.

G. Miyamoto, T. Shinyoshi, J. Yamaguchi, T. Furuhara, T. Maki, and R. Uemori, Crystallography of intragranular ferrite formed on (MnS+ V(C,N)) complex precipitate in austenite, Scripta Mater., 48(2003), No. 4, p. 371.

H.W. Yen, P.Y. Chen, C.Y. Huang, and J.R. Yang, Interphase precipitation of nanometer-sized carbides in a titanium-molybdenum-bearing low-carbon steel, Acta Mater., 59(2011), No. 16, p. 6264.

D. Qiu and W.Z. Zhang, A TEM study of the crystallography of austenite precipitates in a duplex stainless steel, Acta Mater., 55(2007), No. 20, p. 6754.

M.X. Zhang and P.M. Kelly, Crystallography of Mg17Al12 precipitates in AZ91D alloy, Scripta Mater., 48(2003), No. 5, p. 647.

W.Z. Zhang and G.C. Weatherly, On the crystallography of precipitation, Prog. Mater Sci., 50(2005), No. 2, p. 181.

J.G. Jung, J.S. Park, J.Y. Kim, and Y.K. Lee, Carbide precipitation kinetics in austenite of a Nb-Ti-V microalloyed steel, Mater. Sci. Eng. A, 528(2011), No. 16–17, p. 5529.

A. Schneider and G. Inden, Simulation of the kinetics of precipitation reactions in ferritic steels, Acta Mater., 53(2005), No. 2, p. 519.

P. Maugis and M. Gouné, Kinetics of vanadium carbonitride precipitation in steel: a computer model, Acta Mater., 53(2005), No. 12, p. 3359.

Y. Huang, A.M. Zhao, J.G. He, X.P. Wang, Z.G. Wang, and L. Qi, Microstructure, crystallography and nucleation mechanism of NANOBAIN steel, Int. J. Miner. Metall. Mater., 20(2013), No. 12, p. 1155.

Z.N. Bi, J.X. Dong, M.C. Zhang, L. Zheng, and X.S. Xie, Mechanism of α-Cr precipitation and crystallographic relationships between α-Cr and δ phases in Inconel 718 alloy after long-time thermal exposure, Int. J. Miner. Metall. Mater., 17(2010), No. 3, p. 312.

P.J. Apps, J.R. Bowen, and P.B. Prangnell, The effect of coarse second-phase particles on the rate of grain refinement during severe deformation processing, Acta Mater., 51(2003), No. 10, p. 2811.

T. Furuhara, J. Yamaguchi, N. Sugita, G. Miyamoto, and T. Maki, Nucleation of proeutectoid ferrite on complex precipitates in austenite, ISIJ Int., 43(2003), No. 10, p. 1630.

T. Yokomizo, M. Enomoto, O. Umezawa, G. Spanos, and R.O. Rosenberg, Three-dimensional distribution, morphology, and nucleation site of intragranular ferrite formed in association with inclusions, Mater. Sci. Eng. A, 344(2003), No. 1–2, p. 261.

C.C. Koch, Optimization of strength and ductility in nanocrystalline and ultrafine grained metals, Scripta Mater., 49(2003), No. 7, p. 657.

N. Tsuji, Y. Ito, Y. Saito, and Y. Minamino, Strength and ductility of ultrafine grained aluminum and iron produced by ARB and annealing, Scripta Mater., 47(2002), No. 12,p. 893.

S.K. Mishra, S. Das, and S. Ranganathan, Precipitation in high strength low alloy (HSLA) steel: a TEM study, Mater. Sci. Eng. A, 323(2002), No. 1–2, p. 285.

Y.F. Shen, C.M. Wang, and X. Sun, A micro-alloyed ferritic steel strengthened by nanoscale precipitates, Mater. Sci. Eng. A, 528(2011), No. 28, p. 8150.

G. Xu, X.L. Gan, G.J. Ma, F. Luo, and H. Zou, The development of Ti-alloyed high strength microalloy steel, Mater. Des., 31(2010), No. 6, p. 2891.

R. Soto, W. Saikaly, X. Bano, C. Issartel, G. Rigaut, and A. Charai, Statistical and theoretical analysis of precipitates in dual-phase steels microalloyed with titanium and their effect on mechanical properties, Acta Mater., 47(1999), No. 12, p. 3475.

X.P. Mao, X.D. Huo, X.J. Sun, and Y.Z. Chai, Strengthening mechanisms of a new 700MPa hot rolled Ti-microalloyed steel produced by compact strip production, J. Mater. Process. Technol., 210(2010), No. 12, p. 1660.

Y. Takayama and J.A. Szpunar, Stored energy and Taylor factor relation in an Al-Mg-Mn alloy sheet worked by continuous cyclic bending, Mater. Trans., 45(2004), No. 7, p. 2316.

S.I. Wright, M.M. Nowell, and D.P. Field, A review of strain analysis using electron backscatter diffraction, Microsc. Microanal., 17(2011), No. 3, p. 316.

Q. Liu, D. Juul Jensen, and N. Hansen, Effect of grain orientation on deformation structure in cold-rolled polycrystalline aluminium, Acta Mater., 46(1998), No. 16, p. 5819.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, Jj., Wu, R., Liang, W. et al. Effect of nano-sized precipitates on the crystallography of ferrite in high-strength strip steel. Int J Miner Metall Mater 21, 448–454 (2014). https://doi.org/10.1007/s12613-014-0928-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-014-0928-3