Abstract

A new technical prototype for producing Fe-6.5wt% Si electrical steel sheets by directional solidification, heat treatment before rolling, warm rolling, and cold rolling was proposed in the present study. The formability of Fe-6.5wt% Si electrical steel before rolling and the reasonable process parameters of this technical prototype were obtained. Experimental results reveal that the formability of Fe-6.5wt% Si electrical steel is improved significantly under the combination of directional solidification and heat treatment before rolling. Fe-6.5wt% Si electrical steel sheets with the thickness of 0.15 mm, bright surface, few edge cracks, and high rolling yield can be successfully fabricated using this technology without any intermediate annealing during the whole rolling. The combination of directional solidification, heat treatment before rolling, warm rolling, and cold rolling can work as a new process for highly efficient and compact fabrication of Fe-6.5wt% Si electrical steel sheets.

Similar content being viewed by others

References

Y. Tanaka, Y. Takada, M. Abe, and S. Masuda, Magnetic properties of 6.5% Si-Fe sheet and its applications, J. Magn. Magn. Mater., 83(1990), p. 375.

M. Komatsubara, K. Sadahiro, O. Kondo, T. Takamiya, and A. Honda, Newly developed electrical steel for highfrequency use, J. Magn. Magn. Mater., 242–245(2002), p. 212.

Z.Z. He, Electrical Steels, Metallurgical Industry Press, Beijing, 1997, p. 29.

J. Zbroszczyk, W.H. Ciurzyńska, Y. Tanaka, M. Enokizono, J. Olszewski, and M. Hasiak, Microstructure and some magnetic properties of high-silicon Fe-Si sheets, J. Magn. Magn. Mater., 160(1996), p. 141.

T.P.P. Phway and A.J. Moses, Magnetostriction trend of non-oriented 6.5% Si-Fe, J. Magn. Magn. Mater., 320(2008), p. e611.

C. Bolfarini, M.C.A. Silva, A.M. Jorge Jr, C.S. Kiminami, and W.J. Botta, Magnetic properties of spray-formed Fe-6.5%Si and Fe-6.5%Si-1.0%Al after rolling and heat treatment, J. Magn. Magn. Mater., 320(2008), p. e653.

G.K. Tian and X.F. Bi, Study on the Si penetration into Fe sheets using PVD method and its application in the fabrication of Fe-6.5wt.% Si alloys, Surf. Coat. Technol., 204(2010), p. 1295.

L.K. Varga, F. Mazaleyrat, J. Kovac, and A. Kákay, Magnetic properties of rapidly quenched Fe100−x Six (15< x <34) alloys, Mater. Sci. Eng. A, 304–306(2001), p. 946.

W.J. Yuan, J.G. Li, Q. Shen, and L.M. Zhang, A study on magnetic properties of high Si steel obtained through powder rolling processing, J. Magn. Magn. Mater., 320(2008), p. 76.

K. Okada, T. Yamaji, and K. Kasai, Basic investigation of CVD method for manufacturing 6.5%Si steel sheet, ISIJ Int., 36(1996), p. 706.

T. Yamaji, M. Abe, Y. Takada, K. Okada, and T. Hiratani, Magnetic properties and workability of 6.5% silicon steel sheet manufactured in continuous CVD siliconizing line, J. Magn. Magn. Mater., 133(1994), p. 187.

Y.F. Liang, F. Ye, J.P. Lin, Y.L. Wang, and G.L. Chen, Effect of annealing temperature on magnetic properties of cold rolled high silicon steel thin sheet, J. Alloys Compd., 491(2010), p. 268.

Y.F. Liang, J.P. Lin, F. Ye, Y.J. Li, Y.L. Wang, and G.L. Chen, Microstructure and mechanical properties of rapidly quenched Fe-6.5wt.% Si alloy, J. Alloys Compd., 504(2010), Suppl. 1, p. S476.

X.S. Fang, Y.F. Liang, F. Ye, and J.P. Lin, Cold rolled Fe-6.5wt.% Si alloy foils with high magnetic induction, J. Appl. Phys., 111(2012), art. No. 094913.

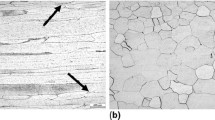

J.X. Xie, H.D. Fu, Z.H. Zhang, and Y.B. Jiang, Deformation twinning feature and its effects on significant enhancement of tensile ductility in columnar-grained Fe-6.5wt.%Si alloy at intermediate temperatures, Intermetallics, 23(2012), p. 20.

H.D. Fu, Q. Yang, Z.H. Zhang, and J.X. Xie, Effects of precipitated phase and order degree on bending properties of an Fe-6.5wt%Si alloy with columnar grains, J. Mater. Res., 26(2011), p. 1711.

Z.H. Zhang, W.P. Wang, H.D. Fu, and J.X. Xie, Effect of quench cooling rate on residual stress, microstructure and mechanical property of an Fe-6.5Si alloy, Mater. Sci. Eng. A, 530(2011), p. 519.

H.D. Fu, Z.H. Zhang, Q. Yang, and J.X. Xie, Strainsoftening behavior of an Fe-6.5wt%Si alloy during warm deformation and its applications, Mater. Sci. Eng. A, 528(2011), p. 1391.

J.S. Shin, J.S. Bae, H.J. Kim, H.M. Lee, T.D. Lee, E.J. Lavernia, and Z.H. Lee, Ordering-disordering phenomena and micro-hardness characteristics of B2 phase in Fe-(5-6.5%)Si alloys, Mater. Sci. Eng. A, 407(2005), p. 282.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fu, Hd., Zhang, Zh., Pan, Hj. et al. Warm/cold rolling processes for producing Fe-6.5wt% Si electrical steel with columnar grains. Int J Miner Metall Mater 20, 535–540 (2013). https://doi.org/10.1007/s12613-013-0762-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-013-0762-z