Abstract

Lithium (Li) is a promising candidate for next-generation battery anode due to its high theoretical specific capacity and low reduction potential. However, safety issues derived from the uncontrolled growth of Li dendrite and huge volume change of Li hinder its practical application. Constructing dendrite-free composite Li anodes can significantly alleviate the above problems. Copper (Cu)-based materials have been widely used as substrates of the composite electrodes due to their chemical stability, excellent conductivity, and good mechanical strength. Copper/lithium (Cu/Li) composite anodes significantly regulate the local current density and decrease Li nucleation overpotential, realizing the uniform and dendrite-free Li deposition. In this review, Cu/Li composite methods including electrodeposition, melting infusion, and mechanical rolling are systematically summarized and discussed. Additionally, design strategies of Cu-based current collectors for high performance Cu/Li composite anodes are illustrated. General challenges and future development for Cu/Li composite anodes are presented and postulated. We hope that this review can provide a comprehensive understanding of Cu/Li composite methods of the latest development of Li metal anode and stimulate more research in the future.

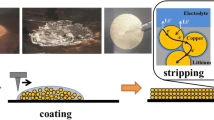

Graphical abstract

摘要

金属锂具有超高的理论比容量 (3860 mAh·g–1) 和极低的电极电势 (− 3.04 V vs. 标准氢电极电势), 有望成为下一代电池负极材料。然而, 充放电过程中, 锂枝晶生长不可控和锂体积变化大导致的严重安全隐患和低效率问题阻碍了锂金属电池的商业化应用。通过构建无枝晶复合锂负极可以显著缓解上述问题。铜基材料因其化学稳定性、优良的导电性和良好的机械强度而被广泛应用于复合锂负极的基体。铜/锂 (Cu/Li) 复合阳极显著的调控了局部电流密度, 降低了锂形核过电位, 实现了均匀无枝晶的锂沉积。本文系统讨论了三种Cu/Li复合方法包括电沉积、热熔融浸润、机械辊压, 并总结了三种方法的优缺点。此外, 文章阐述了用于高性能Cu/Li复合负极的Cu基集流体的设计策略。提出了Cu/Li复合阳极所面临的挑战和未来的发展趋势。我们希望通过本文的综述可以全面了解Cu/Li复合方法在锂金属阳极方面的最新进展, 并激发未来更多的研究。

Reproduced with permission from Ref. [34]. Copyright 2019, Wiley-VCH. d EBSD mappings for bare Cu foil (left), wCu foil (middle) and 100-wCu foil (right); surface morphologies of e bare Cu foil, f wCu foil and g 100-wCu foil after initial Li deposition. Reproduced with permission from Ref. [62]. Copyright 2021, Elsevier

Reproduced with permission from Ref. [63]. Copyright 2019, Elsevier. i XRD patterns for 1 pristine Cu, 2 SF-Cu foils, 3 SF-Cu foil after 100 cycles and 4 SF-Cu foil after 200 cycles; j DFT simulation analysis of surface structure for SF-Cu foil; k CEs of cells with CuNW and SF-CuNW at 3 mA·cm−2 and 3 mAh·cm−2. Reproduced with permission from Ref. [33]. Copyright 2021, Wiley-VCH

Reproduced with permission from Ref. [89]. Copyright 2022, Wiley-VCH. e Schematic diagram of Li plating/stripping for the dynamic intelligent porous Cu (DICu) CC; f schematic illustration of interaction between the Cu microparticles at pristine, low and high Li loading states. Reproduced with permission from Ref. [94]. Copyright 2020, American Chemical Society. g Schematic diagram of electric field distribution in planar Cu (P-Cu) and E-Cu; h simulated analysis of electric field distribution in E-Cu. Reproduced with permission from Ref. [96]. Copyright 2018, Springer Nature. i Simulated analysis of electrolyte and electrode current density of 2.5D micro/nanostructured Cu CC. Reproduced with permission from Ref. [65]. Copyright 2022, Wiley-VCH

Reproduced with permission from Ref. [64]. Copyright 2019, American Chemical Society. b Schematic illustration of Li deposition behaviors on different CCs [39]. Copyright 2021, Elsevier. c Schematic diagram of synthesis process of CF@Cu2Mg; schematic illustration of Li plating behaviors on d bare CF and e CF@Cu2Mg; adsorption structures of single Li atom on f Cu(111) and g Cu2Mg(111) planes; h adsorption energies of single Li atom on Cu(111) and Cu2Mg(111) planes [40]. Copyright 2022, American Chemical Society

Reproduced with permission from Ref. [29]. Copyright 2020, American Chemical Society. Schematic illustration of Li deposition behavior and simulated analysis of Li reaction flux for d Cu foil, e Cu mesh, and f conductivity gradient (CG) host. Reproduced with permission from Ref. [68]. Copyright 2020, Wiley-VCH. Schematic illustration of Li deposition behaviors on g Cu foam (CF) and h nickel–cobalt alloy and zinc oxide onto Cu foam (CNZ); simulation analysis of flow-field state vector of i CF and j CNZ. Reproduced with permission from Ref. [32]. Copyright 2022, Wiley-VCH. Simulation analysis of local current density distribution at k D-Cu@CuSe/electrolyte and l B-Cu/electrolyte interface; simulation analysis of Li-ions flux at m D-Cu@CuSe/electrolyte and n B-Cu/electrolyte interface. Reproduced with permission from Ref. [109]. Copyright 2022, Wiley-VCH

Reproduced with permission from Ref. [53]. Copyright 2017, Elsevier. b Schematic illustration of fabrication process of 3D Li@Cu composite anode. The digital photographs of Li melting infusion into c 3D CuNW and d Cu foam over 20 s. Reproduced with permission from Ref. [54]. Copyright 2018, Elsevier. e Schematic illustration of fabrication process for LCC composite anode. Reproduced with permission from Ref. [117]. Copyright 2021, Wiley-VCH

Reproduced with permission from Ref. [119]. Copyright 2022, Elsevier. d Schematic illustration of synthesis process of C-Li2O@CuNA/CF/Li and 3D Cu/CF. Reproduced with permission from Ref. [113]. Copyright 2020, Elsevier. e Schematic illustration of the different stages for self-propagating strategy during the thermal melting infusion process. Reproduced with permission from Ref. [118]. Copyright 2020, American Chemical Society

Reproduced with permission from Ref. [23]. Copyright 2021, Wiley-VCH. e Schematics of synthetic process for Cu/Li3N rods/Li. Reproduced with permission from Ref. [47]. Copyright 2020, Elsevier. f Schematics of preparation process of Li@MIECS. Reproduced with permission from Ref. [19]. Copyright 2020, Wiley-VCH

Reproduced with permission from Ref. [111]. Copyright 2020, American Chemical Society. i Gibbs free energy changes of reaction between ZnO and Li at different temperatures; j comparison of Gibbs free energy changes of different compounds at 300 °C. Reproduced with permission from Ref. [42]. Copyright 2020, Elsevier

Reproduced with permission from Ref. [128]. Copyright 2017, Wiley-VCH. Schematic illustration of preparation process of e LiI@Cu foil and f LiI/Cu@Li foil electrode; contact angle of electrolyte on g bare Cu and h LiI/Cu@Cu; operando optical microscopy images of i bare Cu and j LiI/Cu during Li plating process. Reproduced with permission from Ref. [130]. Copyright 2022, American Chemical Society

Reproduced with permission from Ref. [132]. Copyright 2019, Springer. c Schematics of preparation processes of vertically oriented Li-Cu-Li arrays; d elemental mapping for vertically oriented Li-Cu-Li arrays. Reproduced with permission from Ref. [21]. Copyright 2019, Wiley-VCH. e Schematic illustration of fabrication process of zeroVE-Li and Li plating behavior of zeroVE-Li and LiMg anodes; f cross-sectional SEM images of zeroVE-Li; g thickness change of different anodes during continuous plating/stripping; h cycling performance comparison of full batteries with LiMg and zeroVE-Li electrodes. Reproduced with permission from Ref. [22]. Copyright 2022, Wiley-VCH

Similar content being viewed by others

References

Wu F, Maier J, Yu Y. Guidelines and trends for next-generation rechargeable lithium and lithium-ion batteries. Chem Soc Rev. 2020;49(5):1569. https://doi.org/10.1039/c7cs00863e.

Xu GL, Gong YD, Miao C, Wang Q, Nie SQ, Xin Y, Wen MY, Liu J, Xiao W. Sn nanoparticles embedded into porous hydrogel-derived pyrolytic carbon as composite anode materials for lithium-ion batteries. Rare Met. 2022;41(10):3421. https://doi.org/10.1007/s12598-022-02073-3.

Yang QY, Yu Z, Li Y, Zhang W, Yuan HW, Li HJ, Ma W, Zhu SM, Li S. Understanding and modifications on lithium deposition in lithium metal batteries. Rare Met. 2022;41(8):2800. https://doi.org/10.1007/s12598-022-01994-3.

Ma LX, Chen TD, Hai CX, Dong SD, He X, Xu Q, Feng H, Xin A, Chen JT, Zhou Y. Surface engineering of Li- and Mn-rich layered oxides for superior Li-ion battery. Tungsten. 2022. https://doi.org/10.1007/s42864-022-00187-w.

Han WW, Ardhi REA, Liu GC. Dual impact of superior SEI and separator wettability to inhibit lithium dendrite growth. Rare Met. 2022;41(2):353. https://doi.org/10.1007/s12598-021-01878-y.

Li HP, Ji XY, Liang JJ. Dual-functional ion redistributor for dendrite-free lithium metal anodes. Rare Met. 2020;39(8):861. https://doi.org/10.1007/s12598-020-01456-8.

Zhang LS, Gao XL, Liu XH, Zhang ZJ, Cao R, Cheng HC, Wang MY, Yan XY, Yang SC. Chain: unlocking informatics-aided design of Li metal anode from materials to applications. Rare Met. 2022;41(5):1477. https://doi.org/10.1007/s12598-021-01925-8.

Ghazi ZA, Sun Z, Sun C, Qi F, An B, Li F, Cheng HM. Key aspects of lithium metal anodes for lithium metal batteries. Small. 2019;15(32):1900687. https://doi.org/10.1002/smll.201900687.

Shi P, Zhang XQ, Shen X, Zhang R, Liu H, Zhang Q. A review of composite lithium metal anode for practical applications. Adv Mater Technol. 2020;5(1):1900806. https://doi.org/10.1002/admt.201900806.

Yang X, Peng Y, Hou J, Liu Y, Jian X. A review for modified Li composite anode: principle, preparation and challenge. Nanotechnol Rev. 2020;9(1):1610. https://doi.org/10.1515/ntrev-2020-0120.

Yu LH, Tao X, Feng SR, Liu JT, Zhang LL, Zhao GZ, Zhu G. Recent development of three-dimension printed graphene oxide and MXene-based energy storage devices. Tungsten. 2022. https://doi.org/10.1007/s42864-022-00181-2.

Jin LM, Xing GG, Qin N, Lu YY, Zheng JS, Zhang CM, Zheng JP. An empirical model for high energy density lithium-(ion) batteries with ultra-thick electrodes. Tungsten. 2022. https://doi.org/10.1007/s42864-022-00163-4.

Zhang G, Zhou X, Liu Z, Mao Y. Challenges and strategies for graphene reinforced copper matrix composites. Chin J Rare Met. 2022;46(7):946. https://doi.org/10.13373/j.cnki.cjrm.XY20030005.

Zhu P, Gastol D, Marshall J, Sommerville R, Goodship V, Kendrick E. A review of current collectors for lithium-ion batteries. J Power Sources. 2021;485:229321. https://doi.org/10.1016/j.jpowsour.2020.229321.

Tan X, Liu X, Xie G. Interfacial microstructure and properties of copper cladding aluminum alloy composites. Chin J Rare Met. 2022;46(7):862. https://doi.org/10.13373/j.cnki.cjrm.xy19100013.

Yan K, Lu ZD, Lee HW, Xiong F, Hsu PC, Li YZ, Zhao J, Chu S, Cui Y. Selective deposition and stable encapsulation of lithium through heterogeneous seeded growth. Nat Energy. 2016;1:16010. https://doi.org/10.1038/nenergy.2016.10.

Pei A, Zheng GY, Shi FF, Li YZ, Cui Y. Nanoscale nucleation and growth of electrodeposited lithium metal. Nano Lett. 2017;17(2):1132. https://doi.org/10.1021/acs.nanolett.6b04755.

Yang CP, Yin YX, Zhang SF, Li NW, Guo YG. Accommodating lithium into 3D current collectors with a submicron skeleton towards long-life lithium metal anodes. Nat Commun. 2015;6:8058. https://doi.org/10.1038/ncomms9058.

Sun C, Lin A, Li W, Jin J, Sun Y, Yang J, Wen Z. In situ conversion of Cu3P nanowires to mixed ion/electron-conducting skeleton for homogeneous lithium deposition. Adv Energy Mater. 2019;10(3):1902989. https://doi.org/10.1002/aenm.201902989.

Liang Z, Lin D, Zhao J, Lu Z, Liu Y, Liu C, Lu Y, Wang H, Yan K, Tao X, Cui Y. Composite lithium metal anode by melt infusion of lithium into a 3D conducting scaffold with lithiophilic coating. PNAS. 2016;113(11):2862. https://doi.org/10.1073/pnas.1518188113.

Cao Z, Li B, Yang S. Dendrite-free lithium anodes with ultra-deep stripping and plating properties based on vertically oriented lithium-copper-lithium arrays. Adv Mater. 2019;31(29):1901310. https://doi.org/10.1002/adma.201901310.

Luo C, Hu H, Zhang T, Wen S, Wang R, An Y, Chi SS, Wang J, Wang C, Chang J, Zheng Z, Deng Y. Roll-to-Roll fabrication of zero-volume-expansion lithium-composite anodes to realize high-energy-density flexible and stable lithium-metal batteries. Adv Mater. 2022;34(38):2205677. https://doi.org/10.1002/adma.202205677.

Qian J, Wang S, Li Y, Zhang M, Wang F, Zhao Y, Sun Q, Li L, Wu F, Chen R. Lithium induced nano-sized copper with exposed lithiophilic surfaces to achieve dense lithium deposition for lithium metal anode. Adv Funct Mater. 2021;31(7):2006950. https://doi.org/10.1002/adfm.202006950.

Røe IT, Schnell SK. Slow surface diffusion on Cu substrates in Li metal batteries. J Mater Chem A. 2021;9(17):11042. https://doi.org/10.1039/d1ta02300d.

Ma X, Liu Z, Chen H. Facile and scalable electrodeposition of copper current collectors for high-performance Li-metal batteries. Nano Energy. 2019;59:500. https://doi.org/10.1016/j.nanoen.2019.02.048.

Lin K, Li T, Chiang SW, Liu M, Qin X, Xu X, Zhang L, Kang F, Chen G, Li B. Facile synthesis of ant-nest-like porous duplex copper as deeply cycling host for lithium metal anodes. Small. 2020;16(37):2001784. https://doi.org/10.1002/smll.202001784.

Pei F, Fu A, Ye W, Peng J, Fang X, Wang MS, Zheng N. Robust lithium metal anodes realized by lithiophilic 3D porous current collectors for constructing high-energy lithium-sulfur batteries. ACS Nano. 2019;13(7):8337. https://doi.org/10.1021/acsnano.9b03784.

Lv Y, Zhang Q, Li C, Ma C, Guan W, Liu X, Ding Y. Bottom-up Li deposition by constructing a multiporous lithiophilic gradient layer on 3D Cu foam for stable Li metal anodes. ACS Sustain Chem Eng. 2022;10(21):7188. https://doi.org/10.1021/acssuschemeng.2c01812.

Yun J, Park BK, Won ES, Choi SH, Kang HC, Kim JH, Park MS, Lee JW. Bottom-up lithium growth triggered by interfacial activity gradient on porous framework for lithium-metal anode. ACS Energy Lett. 2020;5(10):3108. https://doi.org/10.1021/acsenergylett.0c01619.

Li J, Zou P, Chiang SW, Yao W, Wang Y, Liu P, Liang C, Kang F, Yang C. A conductive-dielectric gradient framework for stable lithium metal anode. Energy Storage Mater. 2020;24:700. https://doi.org/10.1016/j.ensm.2019.06.019.

Kim S, Kim Y, Nguyen CT, Jang T, Lee HBR, Byon HR. Promoting lithium electrodeposition towards the bottom of 3-D copper meshes in lithium-based batteries. J Power Sources. 2020;472:228495. https://doi.org/10.1016/j.jpowsour.2020.228495.

Zhang J, Chen H, Wen M, Shen K, Chen Q, Hou G, Tang Y. Lithiophilic 3D copper-based magnetic current collector for lithium-free anode to realize deep lithium deposition. Adv Funct Mater. 2021;32(13):2110110. https://doi.org/10.1002/adfm.202110110.

Fu A, Wang C, Peng J, Su M, Pei F, Cui J, Fang X, Li JF, Zheng N. Lithiophilic and antioxidative copper current collectors for highly stable lithium metal batteries. Adv Funct Mater. 2021;31(15):2009805. https://doi.org/10.1002/adfm.202009805.

Gu Y, Xu HY, Zhang XG, Wang WW, He JW, Tang S, Yan JW, Wu DY, Zheng MS, Dong QF, Mao BW. Lithiophilic faceted Cu(100) surfaces: high utilization of host surface and cavities for lithium metal anodes. Angew Chem Int Ed. 2019;58(10):3092. https://doi.org/10.1002/anie.201812523.

Lai G, Jiao J, Fang C, Jiang Y, Sheng L, Xu B, Ouyang C, Zheng J. The mechanism of Li deposition on the Cu substrates in the anode-free Li metal batteries. Small. 2023;19(3):2205416. https://doi.org/10.1002/smll.202205416.

Yu L, Wang J, Xu ZJ. A perspective on the behavior of lithium anodes under a magnetic field. Small Struct. 2020;2(1):2000043. https://doi.org/10.1002/sstr.202000043.

Yang J, Chen C, Kashif K, Zhao Q, Xu C, Li T, Fang Z, Wu M. Melting lithium alloying to improve the affinity of Cu foil for ultra-thin lithium metal anode. J Colloid Interface Sci. 2023;630:901. https://doi.org/10.1016/j.jcis.2022.10.025.

Zhan YX, Shi P, Ma XX, Jin CB, Zhang QK, Yang SJ, Li BQ, Zhang XQ, Huang JQ. Failure mechanism of lithiophilic sites in composite lithium metal anode under practical conditions. Adv Energy Mater. 2021;12(2):2103291. https://doi.org/10.1002/aenm.202103291.

Meng J, Li C. Planting CuGa2 seeds assisted with liquid metal for selective wrapping deposition of lithium. Energy Storage Mater. 2021;37:466. https://doi.org/10.1016/j.ensm.2021.02.024.

Jiang Y, Liu G, Jiang J, Hu X, Hu L, Li W, Liu X, Zhao B. Cu foam-loaded Cu2Mg alloy with high electrochemical stability to regulate the nucleation of lithium for dendrite-free lithium metal batteries. ACS Sustain Chem Eng. 2022;10(21):7149. https://doi.org/10.1021/acssuschemeng.2c01368.

Ye Y, Liu Y, Wu J, Yang Y. Lithiophilic Li–Zn alloy modified 3D Cu foam for dendrite-free lithium metal anode. J Power Sources. 2020;472:228520. https://doi.org/10.1016/j.jpowsour.2020.228520.

Yue X-Y, Bao J, Qiu Q-Q, Luo R-J, Wang Q-C, Wu X-J, Zhou Y-N. Copper decorated ultralight 3D carbon skeleton derived from soybean oil for dendrite-free Li metal anode. Chem Eng J. 2020;391:123516. https://doi.org/10.1016/j.cej.2019.123516.

Chen M, Cheng L, Chen J, Zhou Y, Liang J, Dong S, Chen M, Wang X, Wang H. Facile and scalable modification of a Cu current collector toward uniform Li deposition of the Li metal anode. ACS Appl Mater Interfaces. 2020;12(3):3681. https://doi.org/10.1021/acsami.9b20777.

Luo K, Leng Z, Li Z, Chen J, Sun N, Xu J, Cao X, Peng Z. Stable Li metal anode in a lithiophilic shuttle. Nanoscale. 2022;14(10):3935. https://doi.org/10.1039/d1nr08194b.

Wang Y, Zhao Z, Zeng W, Liu X, Wang L, Zhu J, Lu B. Hierarchically porous Cu current collector with lithiophilic CuO interphase towards high-performance lithium metal batteries. J Energy Chem. 2021;58:292. https://doi.org/10.1016/j.jechem.2020.10.005.

Zhang R, Li Y, Qiao L, Li D, Deng J, Zhou J, Xie L, Hou Y, Wang T, Tian W, Cao J, Cheng F, Yang B, Liang K, Chen P, Kong B. Atomic layer deposition assisted superassembly of ultrathin ZnO layer decorated hierarchical Cu foam for stable lithium metal anode. Energy Storage Mater. 2021;37:123. https://doi.org/10.1016/j.ensm.2021.01.028.

Park H, Kwon J, Song T, Paik U. Lithiophilic surface treatment of metal- and metallic compound-based frameworks by gas nitriding for lithium metal batteries. J Power Sources. 2020;477:228776. https://doi.org/10.1016/j.jpowsour.2020.228776.

Cui S, Zhai P, Yang W, Wei Y, Xiao J, Deng L, Gong Y. Large-scale modification of commercial copper foil with lithiophilic metal layer for Li metal battery. Small. 2020;16(5):1905620. https://doi.org/10.1002/smll.201905620.

Jia W, Chen T, Wang Y, Qu S, Yao Z, Liu Y, Yin Y, Zou W, Zhou F, Li J. Porous equipotential body with heterogeneous nucleation sites: a novel 3D composite current collector for lithium metal anode. Electrochim Acta. 2019;309:460. https://doi.org/10.1016/j.electacta.2019.04.054.

Jung W-B, Chae OB, Kim M, Kim Y, Hong YJ, Kim JY, Choi S, Kim DY, Moon S, Suk J, Kang Y, Wu M, Jung H-T. Effect of highly periodic Au nanopatterns on dendrite suppression in lithium metal batteries. ACS Appl Mater Interfaces. 2021;13(51):60978. https://doi.org/10.1021/acsami.1c15196.

Gao Y, Cui BF, Wang JJ, Sun ZY, Chen Q, Deng YD, Han XP, Hu WB. Improving Li reversibility in Li metal batteries through uniform dispersion of Ag nanoparticles on graphene. Rare Met. 2022;41(10):3391. https://doi.org/10.1007/s12598-022-02044-8.

Lu LL, Ge J, Yang JN, Chen SM, Yao HB, Zhou F, Yu SH. Free-standing copper nanowire network current collector for improving lithium anode performance. Nano Lett. 2016;16(7):4431. https://doi.org/10.1021/acs.nanolett.6b01581.

Lu LL, Zhang Y, Pan Z, Yao HB, Zhou F, Yu SH. Lithiophilic Cu–Ni core-shell nanowire network as a stable host for improving lithium anode performance. Energy Storage Mater. 2017;9:31. https://doi.org/10.1016/j.ensm.2017.06.004.

Adair KR, Iqbal M, Wang C, Zhao Y, Banis MN, Li R, Zhang L, Yang R, Lu S, Sun X. Towards high performance Li metal batteries: nanoscale surface modification of 3D metal hosts for pre-stored Li metal anodes. Nano Energy. 2018;54:375. https://doi.org/10.1016/j.nanoen.2018.10.002.

Shang H, Zuo Z, Li Y. Highly lithiophilic graphdiyne nanofilm on 3D free-standing Cu nanowires for high-energy-density electrodes. ACS Appl Mater Interfaces. 2019;11(19):17678. https://doi.org/10.1021/acsami.9b03633.

Zhang SS, Fan X, Wang C. An in-situ enabled lithium metal battery by plating lithium on a copper current collector. Electrochem Commun. 2018;89:23. https://doi.org/10.1016/j.elecom.2018.02.011.

Zhang L, Jin Q, Zhao K, Zhang X, Wu L. Lithiophilic Ti3C2Tx-modified Cu foam by electrophoretic deposition for dendrite-free lithium metal anodes. ACS Appl Energy Mater. 2022;5(2):2514. https://doi.org/10.1021/acsaem.1c04035.

Jiang Y, Lv Q, Bao C, Wang B, Ren P, Zhong H, Yang Y, Liu X, Dong Y, Jin F, Wang D, Xiong T, Liu H, Dou S, Wang J, Xue J. Seamless alloying stabilizes solid-electrolyte interphase for highly reversible lithium metal anode. Cell Rep Phys Sci. 2022;3(3):100785. https://doi.org/10.1016/j.xcrp.2022.100785.

Wang R, Shi F, He X, Shi J, Ma T, Jin S, Tao Z. Three-dimensional lithiophilic Cu@Sn nanocones for dendrite-free lithium metal anodes. Sci China Mater. 2020;64(5):1087. https://doi.org/10.1007/s40843-020-1528-5.

Yan K, Sun B, Munroe P, Wang G. Three-dimensional pie-like current collectors for dendrite-free lithium metal anodes. Energy Storage Mater. 2018;11:127. https://doi.org/10.1016/j.ensm.2017.10.012.

Pande V, Viswanathan V. Computational screening of current collectors for enabling anode-free lithium metal batteries. ACS Energy Lett. 2019;4(12):2952. https://doi.org/10.1021/acsenergylett.9b02306.

Kim JY, Chae OB, Wu M, Lim E, Kim G, Hong YJ, Jung WB, Choi S, Kim DY, Gereige I, Suk J, Kang Y, Jung HT. Extraordinary dendrite-free Li deposition on highly uniform facet wrinkled Cu substrates in carbonate electrolytes. Nano Energy. 2021;82:105736. https://doi.org/10.1016/j.nanoen.2020.105736.

Kim YJ, Kwon SH, Noh H, Yuk S, Lee H, Jin HS, Lee J, Zhang JG, Lee SG, Guim H, Kim HT. Facet selectivity of Cu current collector for Li electrodeposition. Energy Storage Mater. 2019;19:154. https://doi.org/10.1016/j.ensm.2019.02.011.

Zhang D, Dai A, Wu M, Shen K, Xiao T, Hou G, Lu J, Tang Y. Lithiophilic 3D porous CuZn current collector for stable lithium metal batteries. ACS Energy Lett. 2019;5(1):180. https://doi.org/10.1021/acsenergylett.9b01987.

Yang I, Jeong J-H, Seok JY, Kim S. Structurally tailored hierarchical Cu current collector with selective inward growth of lithium for high-performance lithium metal batteries. Adv Energy Mater. 2023;13:2202321. https://doi.org/10.1002/aenm.202202321.

Wang LM, Ban XK, Jin ZZ, Peng RR, Chen CS, Chen CH. In situ coating of a lithiophilic interphase on a biporous Cu scaffold with vertical microchannels for dendrite-free Li metal batteries. J Mater Chem A. 2021;9(23):13642. https://doi.org/10.1039/d1ta03037j.

Pu J, Li J, Zhang K, Zhang T, Li C, Ma H, Zhu J, Braun PV, Lu J, Zhang H. Conductivity and lithiophilicity gradients guide lithium deposition to mitigate short circuits. Nat Commun. 2019;10(1):1896. https://doi.org/10.1038/s41467-019-09932-1.

Hong SH, Jung DH, Kim JH, Lee YH, Cho SJ, Joo SH, Lee HW, Lee KS, Lee SY. Electrical conductivity gradient based on heterofibrous scaffolds for stable lithium-metal batteries. Adv Funct Mater. 2020;30(14):1908868. https://doi.org/10.1002/adfm.201908868.

Zheng H, Zhang Q, Chen Q, Xu W, Xie Q, Cai Y, Ma Y, Qiao Z, Luo Q, Lin J, Wang L, Qu B, Sa B, Peng DL. 3D Lithiophilic–lithiophobic–lithiophilic dual-gradient porous skeleton for highly stable lithium metal anode. J Mater Chem A. 2020;8(1):313. https://doi.org/10.1039/c9ta09505e.

Zhang S, Deng W, Zhou X, He B, Liang J, Zhao F, Guo Q, Liu Z. Controlled lithium plating in three-dimensional hosts through nucleation overpotential regulation toward high-areal-capacity lithium metal anode. Mater Today Energy. 2021;21:100770. https://doi.org/10.1016/j.mtener.2021.100770.

Huang S, Zhang W, Ming H, Cao G, Fan LZ, Zhang H. Chemical energy release driven lithiophilic layer on 1m2 commercial brass mesh toward highly stable lithium metal batteries. Nano Lett. 2019;19(3):1832. https://doi.org/10.1021/acs.nanolett.8b04919.

Luan J, Zhang Q, Yuan H, Sun D, Peng Z, Tang Y, Ji X, Wang H. Plasma-strengthened lithiophilicity of copper oxide nanosheet-decorated Cu foil for stable lithium metal anode. Adv Sci. 2019;6(20):1901433. https://doi.org/10.1002/advs.201901433.

Sun C, Yang Y, Bian X, Guan R, Wang C, Lu D, Gao L, Zhang D. Uniform deposition of Li-metal anodes guided by 3D current collectors with in situ modification of the lithiophilic matrix. ACS Appl Mater Interfaces. 2021;13(41):48691. https://doi.org/10.1021/acsami.1c13896.

Zhang C, Lv W, Zhou G, Huang Z, Zhang Y, Lyu R, Wu H, Yun Q, Kang F, Yang Q-H. Vertically aligned lithiophilic CuO nanosheets on a Cu collector to stabilize lithium deposition for lithium metal batteries. Adv Energy Mater. 2018;8(21):1703404. https://doi.org/10.1002/aenm.201703404.

Zhang Z, Xu X, Wang S, Peng Z, Liu M, Zhou J, Shen C, Wang D. Li2O-reinforced Cu nanoclusters as porous structure for dendrite-free and long-lifespan lithium metal anode. ACS Appl Mater Interfaces. 2016;8(40):26801. https://doi.org/10.1021/acsami.6b08775.

Zhou Y, Zhao K, Han Y, Sun Z, Zhang H, Xu L, Ma Y, Chen Y. A nitrogen-doped-carbon/ZnO modified Cu foam current collector for high-performance Li metal batteries. J Mater Chem A. 2019;7(10):5712. https://doi.org/10.1039/c8ta12064a.

Song YX, Lu WY, Chen YJ, Yang H, Wu C, Wei WF, Chen LB, Ouyang XP. Coating highly lithiophilic Zn on Cu foil for high-performance lithium metal batteries. Rare Met. 2022;41(4):1255. https://doi.org/10.1007/s12598-021-01811-3.

Wang Y, Zhao Z, Zeng W, Liu X, Wang L, Zhu J, Lu B. Hierarchically porous Cu current collector with lithiophilic CuxO interphase towards high-performance lithium metal batteries. J Energy Chem. 2021;58:292. https://doi.org/10.1016/j.jechem.2020.10.005.

Liu T, Chen S, Sun W, Lv LP, Du F-H, Liu H, Wang Y. Lithiophilic vertical cactus-like framework derived from Cu/Zn-based coordination polymer through in situ chemical etching for stable lithium metal batteries. Adv Funct Mater. 2021;31(14):2008514. https://doi.org/10.1002/adfm.202008514.

Zhang N, Yu SH, Abruna HD. Regulating lithium nucleation and growth by zinc modified current collectors. Nano Res. 2020;13(1):45. https://doi.org/10.1007/s12274-019-2567-7.

Liu Y, Xu Y, Wang J, Sun Y, Feng X, Xiang H. Regulated lithium deposition behavior by an artificial coating of Cu foil for dendrite-free lithium metal batteries. Mater Today Sustain. 2022;18:100127. https://doi.org/10.1016/j.mtsust.2022.100127.

Wu N, Zhang QY, Guo YJ, Zhou L, Zhang LJ, Wu MX, Wang WP, Yin YX, Sheng P, Xin S. Boron-doped three-dimensional MXene host for durable lithium-metal anode. Rare Met. 2022;41(7):2217. https://doi.org/10.1007/s12598-021-01944-5.

Skriver HL, Rosengaard NM. Surface energy and work function of elemental metals. Phys Rev B Condens Matter. 1992;46(11):7157. https://doi.org/10.1103/physrevb.46.7157.

Zhou YG, Zu XT, Nie JL, Xiao HY. Adsorption of Li on Cu(110): density-functional calculations. Chem Phys. 2009;355(2–3):135. https://doi.org/10.1016/j.chemphys.2008.11.023.

Twigg MV, Spencer MS. Deactivation of copper metal catalysts for methanol decomposition, methanol steam reforming and methanol synthesis. Top Catal. 2003;22:191. https://doi.org/10.1023/a:1023567718303.

Gunther S, Zhou L, Havecker M, Knop-Gericke A, Kleimenov E, Schlogl R, Imbihl R. Adsorbate coverages and surface reactivity in methanol oxidation over Cu(110): an in situ photoelectron spectroscopy study. J Chem Phys. 2006;125:114709. https://doi.org/10.1063/1.2229198.

Feidenhansl R, Grey F, Nielsen M, Besenbacher F, Jensen F, Laegsgaard E, Stensgaard I, Jacobsen KW, Norskov JK, Johnson RL. Oxygen-chemisorption on Cu(110): a model for the C(6x2) structure. Phys Rev Lett. 1990;65(16):2027. https://doi.org/10.1103/PhysRevLett.65.2027.

Peng J, Chen B, Wang Z, Guo J, Wu B, Hao S, Zhang Q, Gu L, Zhou Q, Liu Z, Hong S, You S, Fu A, Shi Z, Xie H, Cao D, Lin C-J, Fu G, Zheng LS, Jiang Y, Zheng N. Surface coordination layer passivates oxidation of copper. Nature. 2020;586(7829):390. https://doi.org/10.1038/s41586-020-2783-x.

Chen J, Li S, Qiao X, Wang Y, Lei L, Lyu Z, Zhao J, Zhang Y, Liu R, Liang Q, Ma Y. Integrated porous Cu host induced high-stable bidirectional Li plating/stripping behavior for practical Li metal batteries. Small. 2022;18(6):2105999. https://doi.org/10.1002/smll.202105999.

Zhao Y, Wei S, Xia L, Pan K, Zhang B, Huang H, Dong Z, Wu H-H, Lin J, Pang H. Sintered Ni metal as a matrix of robust self-supporting electrode for ultra-stable hydrogen evolution. Chem Eng J. 2022;430:133040. https://doi.org/10.1016/j.cej.2021.133040.

Zhao H, Lei D, He YB, Yuan Y, Yun Q, Ni B, Lv W, Li B, Yang QH, Kang F, Lu J. Compact 3D copper with uniform porous structure derived by electrochemical dealloying as dendrite-free lithium metal anode current collector. Adv Energy Mater. 2018;8(19):1800266. https://doi.org/10.1002/aenm.201800266.

Liu H, Wang E, Zhang Q, Ren Y, Guo X, Wang L, Li G, Yu H. Unique 3D nanoporous/macroporous structure Cu current collector for dendrite-free Lithium deposition. Energy Storage Mater. 2019;17:253. https://doi.org/10.1016/j.ensm.2018.07.010.

An Y, Fei H, Zeng G, Xu X, Ci L, Xi B, Xiong S, Feng J, Qian Y. Vacuum distillation derived 3D porous current collector for stable lithium-metal batteries. Nano Energy. 2018;47:503. https://doi.org/10.1016/j.nanoen.2018.03.036.

Chen J, Zhao J, Lei L, Li P, Chen J, Zhang Y, Wang Y, Ma Y, Wang D. Dynamic intelligent Cu current collectors for ultrastable lithium metal anodes. Nano Lett. 2020;20(5):3403. https://doi.org/10.1021/acs.nanolett.0c00316.

Zhang J, Sun D, Tang Z, Xie C, Yang J, Tang J, Zhou X, Tang Y, Wang H. Scalable slurry-coating induced integrated 3D lithiophilic architecture for stable lithium metal anodes. J Power Sources. 2021;485:229334. https://doi.org/10.1016/j.jpowsour.2020.229334.

Zou P, Wang Y, Chiang SW, Wang X, Kang F, Yang C. Directing lateral growth of lithium dendrites in micro-compartmented anode arrays for safe lithium metal batteries. Nat Commun. 2018;9(1):464. https://doi.org/10.1038/s41467-018-02888-8.

Tang Y, Shen K, Lv Z, Xu X, Hou G, Cao H, Wu L, Zheng G, Deng Y. Three-dimensional ordered macroporous Cu current collector for lithium metal anode: uniform nucleation by seed crystal. J Power Sources. 2018;403:82. https://doi.org/10.1016/j.jpowsour.2018.09.083.

Chen KH, Sanchez AJ, Kazyak E, Davis AL, Dasgupta NP. Synergistic effect of 3D current collectors and ALD surface modification for high coulombic efficiency lithium metal anodes. Adv Energy Mater. 2019;9(4):1802534. https://doi.org/10.1002/aenm.201802534.

Wang Y, Wang Z, Lei D, Lv W, Zhao Q, Ni B, Liu Y, Li B, Kang F, He YB. Spherical Li deposited inside 3D Cu skeleton as anode with ultrastable performance. ACS Appl Mater Interfaces. 2018;10(24):20244. https://doi.org/10.1021/acsami.8b04881.

Qiu H, Tang T, Asif M, Huang X, Hou Y. 3D porous Cu current collectors derived by hydrogen bubble dynamic template for enhanced Li metal anode performance. Adv Funct Mater. 2019;29(19):1808468. https://doi.org/10.1002/adfm.201808468.

Yun Q, He Y-B, Lv W, Zhao Y, Li B, Kang F, Yang Q-H. Chemical dealloying derived 3D porous current collector for Li metal anodes. Adv Mater. 2016;28(32):6932. https://doi.org/10.1002/adma.201601409.

Shi Y, Wang Z, Gao H, Niu J, Ma W, Qin J, Peng Z, Zhang Z. A self-supported, three-dimensional porous copper film as a current collector for advanced lithium metal batteries. J Mater Chem A. 2019;7(3):1092. https://doi.org/10.1039/c8ta09384a.

Monroe C, Newman J. Dendrite growth in lithium/polymer systems: a propagation model for liquid electrolytes under galvanostatic conditions. J Electrochem Soc. 2003;150(10):A1377. https://doi.org/10.1149/1.1606686.

Bai P, Li J, Brushett FR, Bazant MZ. Transition of lithium growth mechanisms in liquid electrolytes. Energy Environ Sci. 2016;9(10):3221. https://doi.org/10.1039/c6ee01674j.

Fan H, Dong Q, Gao C, Hong B, Lai Y. Powder-sintering derived 3D porous current collector for stable lithium metal anode. Mater Lett. 2019;234:69. https://doi.org/10.1016/j.matlet.2018.09.067.

Chen Q, Yang Y, Zheng H, Xie Q, Yan X, Ma Y, Wang L, Peng DL. Electrochemically induced highly ion conductive porous scaffolds to stabilize lithium deposition for lithium metal anodes. J Mater Chem A. 2019;7(19):11683. https://doi.org/10.1039/c9ta01834d.

Zhang C, Lyu R, Lv W, Li H, Jiang W, Li J, Cu S, Zhou G, Huang Z, Zhang Y, Wu J, Yang QH, Kang F. A lightweight 3D Cu nanowire network with phosphidation gradient as current collector for high-density nucleation and stable deposition of lithium. Adv Mater. 2019;31(48):1904991. https://doi.org/10.1002/adma.201904991.

Sheikholeslami M, Gorji-Bandpy M. Free convection of ferrofluid in a cavity heated from below in the presence of an external magnetic field. Powder Technol. 2014;256:490. https://doi.org/10.1016/j.powtec.2014.01.079.

Shi Z, Sun Z, Yang X, Lu C, Li S, Yu X, Ding Y, Huang T, Sun J. Synergizing conformal lithiophilic granule and dealloyed porous skeleton toward pragmatic Li metal anodes. Small Sci. 2022;2(5):2100110. https://doi.org/10.1002/smsc.202100110.

Jiang J, Pan Z, Kou Z, Nie P, Chen C, Li Z, Li S, Zhu Q, Dou H, Zhang X, Wang J. Lithiophilic polymer interphase anchored on laser-punched 3D holey Cu matrix enables uniform lithium nucleation leading to super-stable lithium metal anodes. Energy Storage Mater. 2020;29:84. https://doi.org/10.1016/j.ensm.2020.04.006.

Chi S-S, Wang Q, Han B, Luo C, Jiang Y, Wang J, Wang C, Yu Y, Deng Y. Lithiophilic Zn sites in porous CuZn alloy induced uniform Li nucleation and dendrite-free Li metal deposition. Nano Lett. 2020;20(4):2724. https://doi.org/10.1021/acs.nanolett.0c00352.

Jia W, Liu Y, Wang Z, Qing F, Li J, Wang Y, Xiao R, Zhou A, Li G, Yu X, Hu Y-S, Li H, Wang Z, Huang X, Chen L. Low-temperature fusion fabrication of Li–Cu alloy anode with in situ formed 3D framework of inert Licux nanowires for excellent Li storage performance. Sci Bull. 2020;65(22):1907. https://doi.org/10.1016/j.scib.2020.07.012.

Tan L, Li X, Cheng M, Liu T, Wang Z, Guo H, Yan G, Li L, Liu Y, Wang J. In-situ Tailored 3D Li2O@Cu nanowires array enabling stable lithium metal anode with ultra-high coulombic efficiency. J Power Sources. 2020;463:228178. https://doi.org/10.1016/j.jpowsour.2020.228178.

Wu S, Jiao T, Yang S, Liu B, Zhang W, Zhang K. Lithiophilicity conversion of the Cu surface through facile thermal oxidation: boosting a stable Li–Cu composite anode through melt infusion. J Mater Chem A. 2019;7(10):5726. https://doi.org/10.1039/c9ta00466a.

Wu L, Jiang W, Zou H, Ye C, Zhang J, Xu G, Li X, Yue Z, Sun F, Zhou L. Natural forest-inspired Ag lithiophilic porous arrays grown in Cu foam hosts with Bi-continuous electronic/ionic pathways for highly stable Li metal anodes. J Mater Chem A. 2021;9(36):20748. https://doi.org/10.1039/d1ta04927e.

Lin H, Zhang Z, Wang Y, Zhang XL, Tie Z, Jin Z. Template-sacrificed hot fusion construction and nanoseed modification of 3D porous copper nanoscaffold host for stable-cycling lithium metal anodes. Adv Funct Mater. 2021;31(30):2102735. https://doi.org/10.1002/adfm.202102735.

Zhang R, Li Y, Wang M, Li D, Zhou J, Xie L, Wang T, Tian W, Zhai Y, Gong H, Gao M, Liang K, Chen P, Kong B. Super-assembled hierarchical CoO nanosheets-Cu foam composites as multi-level hosts for high-performance lithium metal anodes. Small. 2021;17(23):2101301. https://doi.org/10.1002/smll.202101301.

Huang S, Chen L, Wang T, Hu J, Zhang Q, Zhang H, Nan C, Fan LZ. Self-propagating enabling high lithium metal utilization ratio composite anodes for lithium metal batteries. Nano Lett. 2021;21(1):791. https://doi.org/10.1021/acs.nanolett.0c04546

Zhang N, Zhao T, Wei L, Feng T, Wu F, Chen R. Stable Li/Cu2O composite anodes enabled by a 3D conductive skeleton with lithiophilic nanowire arrays. J Power Sources. 2022;536:231374. https://doi.org/10.1016/j.jpowsour.2022.231374.

Kim JY, Liu G, Tran MX, Ardhi REA, Kim H, Lee JK. Synthesis and characterization of a hierarchically structured three-dimensional conducting scaffold for highly stable Li metal anodes. J Mater Chem A. 2019;7(20):12882. https://doi.org/10.1039/C9TA03062J.

Feng Y, Zhang C, Li B, Xiong S, Song J. Low-volume-change, dendrite-free lithium metal anodes enabled by lithophilic 3D matrix with LiF-enriched surface. J Mater Chem A. 2019;7(11):6090. https://doi.org/10.1039/c8ta10779c.

Qin L, Xu H, Wang D, Zhu J, Chen J, Zhang W, Zhang P, Zhang Y, Tian W, Sun Z. Fabrication of lithiophilic copper foam with interfacial modulation toward high-rate lithium metal anodes. ACS Appl Mater Interfaces. 2018;10(33):27764. https://doi.org/10.1021/acsami.8b07362.

Wang C, Mu X, Yu J, Lu Z, Han J. Scalable hierarchical lithiophilic engineering of metal foam enables stable lithium metal batteries. Chem Eng J. 2022;435:134643. https://doi.org/10.1016/j.cej.2022.134643.

Jia W, Li H, Wang Z, Liu Y, Yang YY, Li J. 3D composite lithium metal with multilevel micro-nano structure combined with surface modification for stable lithium metal anodes. Appl Surf Sci. 2021;570:151159. https://doi.org/10.1016/j.apsusc.2021.151159.

Lu Z, Tai Z, Yu Z, Lagrow AP, Bondarchuk O, Sousa JPS, Meng L, Peng Z, Liu L. Lithium-copper alloy embedded in 3D porous copper foam with enhanced electrochemical performance toward lithium metal batteries. Mater Today Energy. 2021;22:100871. https://doi.org/10.1016/j.mtener.2021.100871.

Chen T, Jianjian S, Xing J, Liu Y, Wang Z, Xiao J, Liu H, Chen Y, Sun X, Li J. Self-formed lithiophilic alloy buffer layer on copper foam framework for advanced lithium metal anodes. ACS Appl Energy Mater. 2021;4:4879. https://doi.org/10.1021/acsaem.1c00477.

Huang HF, Gui YN, Sun F, Liu ZJ, Ning HL, Wu C, Chen LB. In situ formed three-dimensional (3D) lithium-boron (Li–B) alloy as a potential anode for next-generation lithium batteries. Rare Met. 2021;40(12):3494. https://doi.org/10.1007/s12598-021-01708-1.

Li Q, Zhu S, Lu Y. 3D porous Cu current collector/Li-Metal composite anode for stable lithium-metal batteries. Adv Funct Mater. 2017;27(18):1606422. https://doi.org/10.1002/adfm.201606422.

Chen W, Li S, Wang C, Dou H, Zhang X. Targeted deposition in a lithiophilic silver-modified 3D Cu host for lithium-metal anodes. Energy Environ Mater. 2022. https://doi.org/10.1002/eem2.12412.

Liang Q, Chen C, Chen Y, Xiong X. Lil/Cu mixed conductive interface via the mechanical rolling approach for stable lithium anodes in the carbonate electrolyte. ACS Appl Mater Interfaces. 2022;14(34):38931. https://doi.org/10.1021/acsami.2c11632.

Liu Y, Li B, Liu J, Li S, Yang S. Pre-planted nucleation seeds for rechargeable metallic lithium anodes. J Mater Chem A. 2017;5(35):18862. https://doi.org/10.1039/c7ta04932c.

Li T, Shi P, Zhang R, Liu H, Cheng XB, Zhang Q. Dendrite-free sandwiched ultrathin lithium metal anode with even lithium plating and stripping behavior. Nano Res. 2019;12(9):2224. https://doi.org/10.1007/s12274-019-2368-x.

Acknowledgements

This study was financially supported by the National Key Research and Development Program of China (No. 2021YFB2500200), the National Natural Science Foundation of China (No. 52302243) and China Postdoctoral Science Foundation (Nos. 2022M721029 and 2022M721030)

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, B., Ma, JP., Zhao, Y. et al. Design and application of copper/lithium composite anodes for advanced lithium metal batteries. Rare Met. 43, 942–970 (2024). https://doi.org/10.1007/s12598-023-02477-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-023-02477-9