Abstract

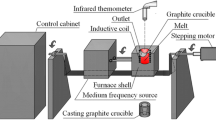

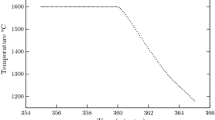

Boron removal from metallurgical-grade silicon (MG-Si) using CaO–SiO2 slag was studied by employing a medium-frequency electromagnetic induction furnace. The relationship between the optical basicity (Λ) of the CaO–SiO2 slag and the distribution coefficient of boron (L B) was investigated. Consequently, the local minimum and maximum L B values of 0.72 and 1.58 are obtained when Λ = 0.56 and Λ = 0.71, respectively. The boron content in MG-Si decreases gradually with refinement time increasing, down to a minimum value of 4.73 × 10−6. The controlling step in the removal of boron from MG-Si is not the chemical reaction at the interface of the slag and silicon. Instead, the controlling step is a diffusion mass transfer, in which boron impurities diffuse from molten silicon to the interface of the slag and silicon, or B2O3 formed by the chemical reaction diffuses from the slag–silicon interface to molten slag.

Similar content being viewed by others

References

Bjerke H. Removal of boron from silicon by slag treatment and by evaporation of boron from slag in hydrogen atmosphere. Norwegian: Norwegian University of Science and Technology; 2012. 14.

Teixeira LAV, Morita K. Removal of boron from molten silicon using CaO–SiO2 based slags. ISIJ Int. 2009;49(6):783.

Teixeira LAV, Tokuda Y, Yoko T, Morita K. Behavior and state of boron in CaO–SiO2 slags during refining of solar grade silicon. ISIJ Int. 2009;49(6):777.

Wu JJ, Li YL, Ma WH, Wei KX, Yang B, Dai YN. Boron removal in purifying metallurgical grade silicon by CaO–SiO2 slag refining. Trans Nonferrous Metals Soc China. 2014;24(4):1231.

Ding Z, Ma WH, Wei KX, Wu JJ, Zhou Y, Xie KQ. Boron removal from metallurgical-grade silicon using lithium containing slag. J Non-Cryst Solids. 2012;358(18):2708.

Ito N, Kondo J, Okazawa K, Okajima M. Method for producing high purity silicon. US Patent; 20080311020. 2008.

Ito N, Kondo J, Okazawa K, Okajima M. Using solar battery; migration of impurities; supplying oxidizer and slay to molten silicon. US Patent; 20080247936. 2008.

Ito N, Kondo J, Okazawa K, Okajima M. Method for producing high purity silicon. US Patent; 20080274031. 2008.

Johnston MD, Barati M. Distribution of impurity elements in slag-silicon equilibria for oxidative refining of metallurgical silicon for solar cell applications. Sol Energy Mater Sol Cells. 2010;94(12):2085.

Johnston MD, Barati M. Effect of slag basicity and oxygen potential on the distribution of boron and phosphorus between slag and silicon. J Non-Cryst Solids. 2011;357(3):970.

Li JY, Zhang L, Tan Y, Jiang DC, Wang DK, Li YQ. Research of boron removal from polysilicon using CaO–Al2O3–SiO2–CaF2 slags. Vacuum. 2014;103:33.

Luo DW, Liu N, Lu YP, Zhang GL, Li TJ. Removal of boron from metallurgical grade silicon by electromagnetic induction slag melting. Trans Nonferrous Metals Soc China. 2011;21(5):1178.

Jia BJ, Wu JJ, Ma WH, Yang B, Liu DC, Dai YN. Boron removal from metallurgical grade silicon using a FeCl2 molten salt refining technique. J Min Metall Sect B. 2013;49(3):257.

Jia BJ, Wu JJ, Ma WH, Li YL. Removal of boron from metallurgical grade silicon by chloride molten salt. Adv Mater Res. 2013;634–638:3084.

Li YL, Wu JJ, Ma WH, Wei KX, Xie KQ. Kinetics of boron removal from metallurgical grade silicon using a slag refining technique based on CaO–SiO2 binary system. Sep Sci Technol. 2014;49(12):1946.

Safarian J, Tranell G, Tangstad M. Thermodynamic and kinetic behavior of B and Na through the contact of B-doped silicon with Na2O–SiO2 slags. Metall Mater Trans B. 2013;44(3):571.

White JF, Sichen D. Mass transfer in slag refining of silicon with mechanical stirring: transient interfacial phenomena. Metall Mater Trans B. 2014;45(1):96.

Fang M, Lu CH, Huang LQ, Lai HX, Chen J, Li JT, Ma WH, Xing PF, Luo XT. Effect of calcium-based slag treatment on hydrometallurgical purification of metallurgical-grade silicon. Ind Eng Chem Res. 2014;53(2):972.

Fang M, Lu CH, Huang LQ, Lai HX, Chen J, Yang XB, Li JT, Ma WH, Xing PF, Luo XT. Multiple slag operation on boron removal from metallurgical-grade silicon using Na2O–SiO2 slags. Ind Eng Chem Res. 2014;53(30):12054.

Fang M, Lu CH, Huang LQ, Lai HX, Chen J, Li JT, Ma WH, Xing PF, Luo XT. Separation of metal impurities from metallurgical grade silicon via CaO–SiO2–CaF2 slag treatment followed by leaching with hydrochloric acid. Sep Sci Technol. 2014;49(14):2261.

Ding Z, Ma WH, Wei KX, Wu JJ, Yang B, Dai YN. Latest progress in purification of metallurgical grade silicon by slag oxidation refining. Chin J Vac Sci Technol. 2013;33(2):185.

Wu JJ, Ma WH, Jia BJ, Yang B, Liu DC, Dai YN. Boron removal from metallurgical grade silicon using a CaO–Li2O–SiO2 molten slag refining technique. J Non-Cryst Solids. 2012;358(23):3079.

Acknowledgments

This study was financially supported by the National Natural Science Foundation of China (Nos. 51461027 and 51104080).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wei, KX., Lu, HF., Ma, WH. et al. Boron removal from metallurgical-grade silicon by CaO–SiO2 slag refining. Rare Met. 34, 522–526 (2015). https://doi.org/10.1007/s12598-015-0496-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-015-0496-3