Abstract

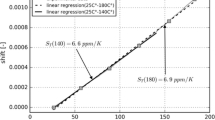

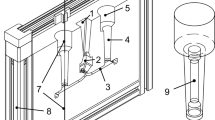

Out of autoclave (OoA) processing techniques, such as liquid composite moulding techniques (LCM) and, particularly, the vacuum-assisted resin infusion (VARI) technique, are being used, with increasing success, in replacement of prepreg/autoclave technologies to produce structural aircraft/aerospace polymer composite parts, due to its better cost effectiveness and competitiveness. This work aims to embed Fibre Bragg grating (FBG) sensors to monitor the VARI manufacturing of carbon fibre reinforced polymer (CFRP) composites and evaluate the associated phenomena: ambient curing and post curing reactions and resulting residual strains. The curing kinetics of the epoxy resin system alone was initially studied through isothermal differential scanning calorimetry (DSC) tests and applying the isoconversional Friedman method, and further studied by strain monitoring during ambient curing and post curing resorting to FBG sensors. The FBG sensors in the CFRP laminates were able to detect a subtle increase of strain as infusion of the CFRP started and to measure decreasing strain as resin filled in the dry fabric layers. Subtle strain decrease revealed forming crosslink bonds. Compressive strains measured by the FBG sensors during post curing show that further crosslink takes place. A comparison of resultant residual strains was made between specimens with embedded FBG sensors on small-diameter optical fibres (SDOF) and on large-diameter optical fibres (LDOF).

Similar content being viewed by others

References

Giurgiutiu, V.: “Introduction”, in Structural Health Monitoring of Aerospace Composites, pp. 1–23. Elsevier, USA (2016)

Pierce, R.S., Falzon, B.G., Thompson, M.C.: A multi-physics process model for simulating the manufacture of resin-infused composite aerostructures. Compos. Sci. Technol. 149, 269–279 (2017)

Sas, H.S., Šimáček, P., Advani, S.G.: A methodology to reduce variability during vacuum infusion with optimized design of distribution media. Compos. Part A Appl. Sci. Manuf. 78, 223–233 (2015)

Komarov, V.A., Kurkin, E.I., Spirina, M.O.: Composite aerospace structures shape distortion during all stages of vacuum infusion production. Procedia Eng. 185, 139–145 (2017)

Tita, V., De Carvalho, J., Vandepitte, D.: Failure analysis of low velocity impact on thin composite laminates: experimental and numerical approaches. Compos. Struct. 83, 413–428 (2008)

Ramakrishnan, M., Rajan, G., Semenova, Y., Farrell, G.: Overview of fiber optic sensor technologies for strain/temperature sensing applications in composite materials. Sensors 16(1), 99 (2016)

Guo, J.Y.H., Xiao, G., Mrad, N.: Fiber optic sensors for structural health monitoring of air platforms. Sensors 11, 3687–3705 (2011)

Chambers, A.R., Mowlem, M.C., Dokos, L.: Evaluating impact damage in CFRP using fibre optic sensors. Compos. Sci. Technol. 67(6), 1235–1242 (2007)

Zhao, Y., Liao, Y.: Discrimination methods and demodulation techniques for fiber Bragg grating sensors. Opt. Lasers Eng. 41(1), 1–18 (2004)

Zhou, G., Sim, L.M.: Damage detection and assessment in fibre-reinforced composite structures with embedded fibre optic sensors—review. Smart Mater. Struct. 11, 925–939 (2002)

Giurgiutiu, V.: Fiber-optic sensors. In: Structural health monitoring of aerospace composites, pp. 249–296. Academic Press, London (2016)

Di Sante, R.: Fibre optic sensors for structural health monitoring of aircraft composite structures: recent advances and applications. Sensors 15(8), 18666–18713 (2015)

Qiu, Y., Wang, Q., Zhao, H., Chen, J., Wang, Y.: Review on composite structural health monitoring based on fiber Bragg grating sensing principle. J. Shanghai Jiaotong Univ. 18(2), 129–139 (2013)

Chehura, E., Skordos, A.A., Ye, C.-C., James, S.W., Partridge, I.K., Tatam, R.P.: Strain development in curing epoxy resin and glass fibre/epoxy composites monitored by fibre Bragg grating sensors in birefringent optical fibre. Smart Mater. Struct. 14, 354–362 (2005)

Leng, J., Asundi, A.: Structural health monitoring of smart composite materials by using EFPI and FBG sensors. Sens. Actuat. A: Phys. 103, 330–340 (2003)

Kang, H.-K., Kang, D.-H., Bang, H.-J., Hong, C.-S., Kim, C.-G.: Cure monitoring of composite laminates using fiber optic sensors. Smart Mater. Struct. 11(2), 279–287 (2002)

Takeda, S., Okabe, Y., Takeda, N.: Delamination detection in CFRP laminates with embedded small-diameter fiber Bragg grating sensors. Compos. Part A 33(2013), 971–980 (2002)

Satori, K., Fukuchi, K., Kurosawa, Y., Hongo, A., Takeda, N.: Polyimide-coated small-diameter optical fiber sensors for embedding in composite laminate structures. Smart. Struct. Mater. Sens. Phenom. Meas. Instrum. Smart. Struct. Mater. 4328, 285–294 (2001)

Liu, R.-M., Liang, D.-K.: Natural frequency detection of smart composite structure by small diameter fiber Bragg grating. J. Vib. Control 21, 2896–2902 (2014)

Minakuchi, S., Okabe, Y., Takeda, N.: Real-time detection of debonding between honeycomb core and facesheet using a small-diameter FBG sensor embedded in adhesive layer. J. Sandw. Struct. Mater. 9(1), 9–33 (2007)

Ding, G., Cao, H., Xie, C.: Multipoint cure monitoring of temperature and strain of carbon fibre-reinforced plastic shafts using fibre Bragg grating sensors. Nondestruct. Test. Eval. 34(2), 117–134 (2019)

ASTM International: ASTM E2070-13 standard test methods for kinetic parameters by differential scanning calorimetry using isothermal methods. ASTM Int. i, 1–12 (2018)

Friedman, H.L.: Kinetics of thermal degradation of char-forming plastics from thermogravimetry. Application to a phenolic plastic. J. Polym. Sci. Part C 6(1), 183–195 (1964)

Fernandez-d’Arlas, B., Rueda, L., Stefani, P.M., de la Caba, K., Mondragon, I., Eceiza, A.: Kinetic and thermodynamic studies of the formation of a polyurethane based on 1,6-hexamethylene diisocyanate and poly(carbonate-co-ester)diol. Thermochim. Acta 459, 94–103 (2007)

Wuzella, G., Mahendran, A.R., Beuc, C., Lammer, H.: Isoconversional cure kinetics of a novel thermosetting resin based on linseed oil. J. Therm. Anal. Calorim. (2020)

Barton, J.M.: The application of differential scanning calorimetry (DSC) to the study of epoxy resin curing reactions. Adv. Polym. Sci. 72, 111–154 (1985)

Funding

The authors acknowledge the support of the European Regional Development Fund [grant number NORTE-01-0145-FEDER-000015]; and of the European Space Agency through the Network/Partnering Initiative Program.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they do not have known competing financial interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rocha, H., Semprimoschnig, C. & Nunes, J.P. Small-diameter optical fibre sensor embedment for ambient temperature cure monitoring and residual strain evaluation of CFRP composite laminates produced by vacuum-assisted resin infusion. CEAS Space J 13, 353–367 (2021). https://doi.org/10.1007/s12567-021-00357-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12567-021-00357-5