Abstract

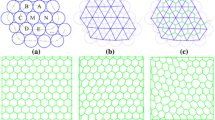

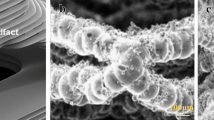

Benefited from the rapid development of additive manufacturing (AM), inhomogeneous cellular structures have attracted many interests for their superior structural and functional performance. Recently proposed density-based design methods have been shown to provide great computational efficiency and obtain structures with excellent performance. To achieve better structural performance while considering AM constraints, an improved density-based design method which introduces solid and void units into the design domain is proposed in this paper. First, based on homogenization theory and solid-body analysis, unit parameters of different preset unit relative densities are determined. And a unit effective property interpolation model is constructed. Then, the macro relative density layout is optimized with density methods. In the optimization process, an efficient density filter is proposed to increase the optimization domain and satisfy minimal feature size constraint. Finally, the structure reconstruction algorithm automatically constructs the optimized cellular structure based on the unit and density information obtained in the first two processes. Numerical examples show that the proposed method efficiently obtains inhomogeneous cellular structures with better performance, compared with existing density-based methods.

Similar content being viewed by others

References

Gibson, L. J., & Ashby, M. F. (1999). Cellular solids: Structure and properties. Cambridge: Cambridge University Press.

Banhart, J. (2001). Manufacture, characterisation and application of cellular metals and metal foams. Progress in Materials Science,46(6), 559–632.

Lim, Y. E., Park, J. H., & Park, K. (2018). Automatic design of 3D conformal lightweight structures based on a tetrahedral mesh. International Journal of Precision Engineering and Manufacturing - Green Technology,5, 499–506.

Chu, J., Engelbrecht, S., Graf, G., & Rosen, D. W. (2010). A comparison of synthesis methods for cellular structures with application to additive manufacturing. Rapid Prototyping Journal,16, 275–283.

Tang, Y., Kurtz, A., & Zhao, Y. F. (2015). Bidirectional Evolutionary Structural Optimization (BESO) based design method for lattice structure to be fabricated by additive manufacturing. Computer-Aided Design,69, 91–101.

Ryan, G., Pandit, A., & Apatsidis, D. P. (2006). Fabrication methods of porous metals for use in orthopaedic applications. Biomaterials,27(13), 2651–2670.

Lee, D., Kim, H., Sim, J., et al. (2019). Trends in 3D printing technology for construction automation using text mining. International Journal of Precision Engineering and Manufacturing.,20, 871–882.

Doubrovski, E. L., Verlinden, J. C., & Geraedts, J. M. P. (2011). Optimal design for additive manufacturing: Opportunities and challenges. In ASME 2011 international design engineering technical conferences and computers and information in engineering conference (pp. 635–646).

Park, J.-H., Goo, B., & Park, K. (2019). Topology optimization and additive manufacturing of customized sports item considering orthotropic anisotropy. International Journal of Precision Engineering and Manufacturing.,20, 1443–1450.

Francois, M. M., Sun, A., King, W. E., Henson, N. J., et al. (2017). Modeling of additive manufacturing processes for metals: Challenges and opportunities. Current Opinion in Solid State and Materials Science 21(LA-UR-16-24513).

Tao, W., & Ming, C. L. (2016). Design of lattice structure for additive manufacturing. In International symposium on flexible automation (pp. 325–332).

Brackett, D. J., Ashcroft, I. A., Wildman, R. D., et al. (2014). An error diffusion based method to generate functionally graded cellular structures. Computers & Structures,138, 102–111.

Dorn, W. S., Gomory, R. E., & Greenberg, H. J. (1964). Automatic design of optimal structures. Journal de Mecanique,3, 25–52.

Savio, G., Meneghello, R., & Concheri, G. (2017). Optimization of lattice structures for Additive Manufacturing Technologies. In B. Eynard, V. Nigrelli, S. Oliveri, G. Peris-Fajarnes, & S. Rizzuti (Eds.), Advances on mechanics, design engineering and manufacturing (pp. 213–222). Cham: Springer.

Chang, P. S., & Rosen, D. W. (2011). An improved size, matching, and scaling method for the design of deterministic mesoscale truss structures. Proceedings of the ASME Design Engineering Technical Conference,2, 697–707.

Nguyen, J., Park, S., & Rosen, D. (2013). Heuristic optimization method for cellular structure design of light weight components. International Journal of Precision Engineering and Manufacturing,14, 1071–1078.

Alzahrani, M., Choi, S. K., & Rosen, D. W. (2015). Design of truss-like cellular structures using relative density mapping method. Materials and Design,85, 349–360.

Alzahrani, M. A. (2014). Design of truss-like cellular structures using density information from topology optimization. European Journal of Operational Research,103(1), 198–208.

Zhang, P., Toman, J., Yu, Y., et al. (2015). Efficient design-optimization of variable-density hexagonal cellular structure by additive manufacturing: Theory and validation. Journal of Manufacturing Science and Engineering,137(2), 021004.

Cheng, L., Zhang, P., Biyikli, E., et al. (2017). Efficient design optimization of variable-density cellular structures for additive manufacturing: Theory and experimental validation. Rapid Prototyping Journal,23, 660–677.

Wu, T., Liu, K., & Tovar, A. (2017). Multiphase topology optimization of lattice injection molds. Computers & Structures,192, 71–82.

Kuo, T. C., Huang, S. H., & Zhang, H. C. (2001). Design for manufacture and design for “X”: Concepts, applications, and perspectives. Computer and Industrial Engineering,41, 241–260.

Gorguluarslan, R. M., Gandhi, U. N., Song, Y., et al. (2017). An improved lattice structure design optimization framework considering additive manufacturing constraints. Rapid Prototyping Journal,23, 305–319.

Hassani, B., & Hinton, E. (1998). A review of homogenization and topology optimization I—Homogenization theory for media with periodic structure. Computers & Structures,69, 707–717.

Hassani, B., & Hinton, E. (1998). A review of homogenization and topology opimization II—Analytical and numerical solution of homogenization equations. Computers & Structures,69, 719–738.

Gibson, L. J., & Ashby, M. F. (2014). Cellular solids: Structure and properties. Cambridge University Press,33, 487–488.

Zhang, W., Dai, G., Wang, F., et al. (2007). Using strain energy-based prediction of effective elastic properties in topology optimization of material microstructures. Acta Mechanica Sinica,23(1), 77–89.

Liu, J., Zheng, Y., Ma, Y., et al. (2019). A topology optimization method for hybrid subtractive–additive remanufacturing. International Journal of Precision Engineering and Manufacturing-Green Technology.

Kim, H., Seong, H., & Yoo, J. (2019). Study on the clear boundary determination from results of the phase field design method. International Journal of Precision Engineering and Manufacturing.,20, 1553–1561.

Bendsøe, M. P., & Sigmund, O. (2003). Topology optimization: theory, methods, and applications. Berlin: Springer.

Bendsøe, M. P., & Sigmund, O. (1999). Material interpolation schemes in topology optimization. Archive of Applied Mechanics,69, 635–654.

Bruns, T. E., & Tortorelli, D. A. (2001). Topology optimization of non-linear elastic structures and compliant mechanisms. Computer Methods in Applied Mechanics and Engineering,190, 3443–3459.

Bourdin, B. (2001). Filters in topology optimization. International Journal for Numerical Methods in Engineering,50, 2143–2158.

Andreassen, E., Clausen, A., Schevenels, M., et al. (2011). Efficient topology optimization in MATLAB using 88 lines of code. Structural and Multidisciplinary Optimization,43, 1–16.

Svanberg, K. (1987). The method of moving asymptotes: A new method for structural optimization. International Journal for Numerical Methods in Engineering,24, 359–373.

Liu, J., & Ma, Y. (2016). A survey of manufacturing oriented topology optimization methods. Advances in Engineering Software,100, 161–175.

Brackett, D., Ashcroft, I., & Hagues, R. (2013). Topology optimization for additive manufacturing. Journal of Chemical Information and Modeling,53, 1689–1699.

Liu, J., et al. (2018). Current and future trends in topology optimization for additive manufacturing. Structural and Multidisciplinary Optimization,57, 2457–2483.

Gaynor, A. T., & Guest, J. K. (2016). Topology optimization considering overhang constraints: Eliminating sacrificial support material in additive manufacturing through design. Structural and Multidisciplinary Optimization,54, 1157–1172.

Langelaar, M. (2017). An additive manufacturing filter for topology optimization of print-ready designs. Structural and Multidisciplinary Optimization,55, 871–883.

Allaire, G., Dapogny, C., Estevez, R., Faure, A., & Michailidis, G. (2017). Structural optimization under overhang constraints imposed by additive manufacturing technologies. Journal of Computational Physics,351, 295–328.

Li, D., Dai, N., Zhou, X., Huang, R., & Liao, W. (2018). Self-supporting interior structures modeling for buoyancy optimization of computational fabrication. International Journal of Advanced Manufacturing Technology,95, 825–834.

Zhao, J., Zhang, M., Zhu, Y., Li, X., Wang, L., & Hu, J. (2019). A novel optimization design method of additive manufacturing oriented porous structures and experimental validation. Materials and Design,163, 107550.

Jiang, J., Xu, X., & Stringer, J. (2018). Support structures for additive manufacturing: A review. Journal of Manufacturing and Materials Processing.,2, 64.

Górski, F., Wichniarek, R., Kuczko, W., Zawadzki, P., & Buń, P. (2015). Strength of abs parts produced by fused deposition modelling technology—A critical orientation problem. Advances in Science and Technology Research Journal,9, 12–19.

Acknowledgements

The author thanks Prof. Krister Svanberg for use of the MMA optimizer. This work was supported in part by the National Natural Science Foundation of China under Grant 51677104.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhu, Y., Zhao, J., Zhang, M. et al. An Improved Density-Based Design Method of Additive Manufacturing Fabricated Inhomogeneous Cellular-Solid Structures. Int. J. Precis. Eng. Manuf. 21, 103–116 (2020). https://doi.org/10.1007/s12541-019-00230-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-019-00230-w