Abstract

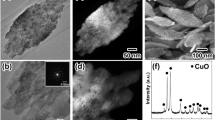

This paper reports the effects of the stirring rate of the solution, boric acid concentration, and applied current density on the formation of the copper-cuprous co-electrodeposited structure. For copper-cuprous co-electrodeposition, 0.5 M CuSO4·5H2O solution was used. When electrodeposition was performed via stirring and the addition of boric acid, pillar-type electrodeposited structures were formed. On the other hand, when electrodeposition was carried out without stirring or the addition of boric acid, hill-type electrodeposited structures were formed. Development of the pillar structure was promoted by increasing the boric acid concentration and the stirring rate. The electrodeposited structure was applied to surface modification in order to verify its industrial effectiveness. When the concentration of the added boric acid was higher than 0.5 M and the stirring rate of the solution was 200 rpm, the fabricated specimens showed superhydrophobic properties after hydrophobic layer coating.

Similar content being viewed by others

References

Nosonovsky, M. and Bhushan, B., “Biomimetic Superhydrophobic Surfaces: Multiscale Approach,” Nano Letters, Vol. 7, No. 9, pp. 2633–2637, 2007.

Yoon, Y., Kim, D., and Lee, J.-B., “Hierarchical Micro/Nano Structures for Super-Hydrophobic Surfaces and Super-Lyophobic Surface Against Liquid Metal,” Micro and Nano Systems Letters, Vol. 2, No. 3, pp. 1–18, 2014. (DOI: 10.1186/s40486-014-0003-x)

Ahuja, T. and Kumar, D., “Recent Progress in the Development of Nano-Structured Conducting Polymers/Nanocomposites for Sensor Applications,” Sensors and Actuators B: Chemical, Vol. 136, No. 1, pp. 275–286, 2009.

Fang, B., Kim, J. H., Kim, M., and Yu, J.-S., “Ordered Hierarchical Nanostructured Carbon as a Highly Efficient Cathode Catalyst Support in Proton Exchange Membrane Fuel Cell,” Chemistry of Materials, Vol. 21, No. 5, pp. 789–796, 2009.

Li, L., Chen, S., Xu, C., Zhao, Y., Rudawski, N. G., and Ziegler, K. J., “Comparing Electron Recombination via Interfacial Modifications in Dye-Sensitized Solar Cells,” ACS Applied Materials & Interfaces, Vol. 6, No. 23, pp. 20978–20984, 2014.

Zhao, Y., Zhai, J., Tan, S., Wang, L., Jiang, L., and Zhu, D., “TiO2 Micro/Nano-Composite Structured Electrodes for Quasi-Solid-State Dye-Sensitized Solar Cells,” Nanotechnology, Vol. 17, No. 9, pp. 2090–2097, 2006.

Lee, C. H., Jung, P. G., Lee, S. M., Park, S. H., Shin, B. S., et al., “Replication of Polyethylene Nano-Micro Hierarchical Structures Using Ultrasonic Forming,” Journal of Micromechanics and Microengineering, Vol. 20, No. 3, Paper No. 035018, 2010.

Lee, S. M., Jung, I. D., and Ko, J. S., “The Effect of the Surface Wettability of Nanoprotrusions Formed on Network-Type Microstructures,” Journal of Micromechanics and Microengineering, Vol. 18, No. 12, Paper No. 125007, 2008.

Park, S. H., Lee, S. H., Yang, D.-Y., Kong, H. J., and Lee, K.-S., “Subregional Slicing Method to Increase Three-Dimensional Nanofabrication Efficiency in Two-Photon Polymerization,” Applied Physics Letters, Vol. 87, No. 15, Paper No. 154108, 2005.

Meng, F., Morin, S. A., Forticaux, A., and Jin, S., “Screw Dislocation Driven Growth of Nanomaterials,” Accounts of Chemical Research, Vol. 46, No. 7, pp. 1616–1626, 2013.

Lee, J. M., Bae, K. M., Jung, K. K., Jeong, J. H., and Ko, J. S., “Creation of Microstructured Surfaces Using Cu–Ni Composite Electrodeposition and their Application to Superhydrophobic Surfaces,” Applied Surface Science, Vol. 289, pp. 14–20, 2014.

Lee, J. M., Jung, K. K., Lee, S. H., and Ko, J. S., “One-Step Fabrication of Nickel Nanocones by Electrodeposition Using CaCl2 · 2H2O as Capping Reagent,” Applied Surface Science, Vol. 369, pp. 163–169, 2016.

Chang, J.-K., Hsu, S.-H., Sun, I.-W., and Tsai, W.-T., “Formation of Nanoporous Nickel by Selective Anodic Etching of the Nobler Copper Component from Electrodeposited Nickel-Copper Alloys,” The Journal of Physical Chemistry C, Vol. 112, No. 5, pp. 1371–1376, 2008.

Deng, Y., Ling, H., Feng, X., Hang, T., and Li, M., “Electrodeposition and Characterization of Copper Nanocone Structures,” CrystEngComm, Vol. 17, No. 4, pp. 868–876, 2015.

Wang, P., Zhang, D., and Qiu, R., “Extreme Wettability due to Dendritic Copper Nanostructure Via Electrodeposition,” Applied Surface Science, Vol. 257, No. 20, pp. 8438–8442, 2011.

Lee, J. M., Jung, K. K., and Ko, J. S., “Formation of Nickel Microcones by Using an Electrodeposition Solution Containing H3BO3,” Current Applied Physics, Vol. 16, No. 3, pp. 261–266, 2016.

Lee, J. M., Lee, S. H., Kim, Y. J., and Ko, J. S., “Effect of the Diffusion Rate of the Copper Ions on the Co-Electrodeposition of Copper And Nickel,” Int. J. Precis. Eng. Manuf., Vol. 14, No. 11, pp. 2009–2014, 2013.

Gu, C. and Zhang, T.-Y., “Electrochemical Synthesis of Silver Polyhedrons and Dendritic Films with Superhydrophobic Surfaces,” Langmuir, Vol. 24, No. 20, pp. 12010–12016, 2008.

Shao, W. and Zangari, G., “Dendritic Growth and Morphology Selection in Copper Electrodeposition from Acidic Sulfate Solutions Containing Chlorides,” The Journal of Physical Chemistry C, Vol. 113, No. 23, pp. 10097–10102, 2009.

Hu, S., Huang, W., and Li, Z., “Facile Fabrication of 3D Dendritic Gold Nanostructures with an Ausn Alloy by Square Wave Potential Pulse,” Materials Letters, Vol. 64, No. 11, pp. 1257–1260, 2010.

Lee, J. M., Jung, K. K., and Ko, J. S., “Growth Mechanism and Application of Nanostructures Fabricated by a Copper Sulfate Solution Containing Boric Acid,” Journal of the Electrochemical Society, Vol. 163, No. 8, pp. D407–D413, 2016.

Ng, S. Y. and Ngan, A. H. W., “Additive Free Co-Deposition of Nanocrystalline Copper/Cuprous Oxide by Electrodeposition,” Journal of the Electrochemical Society, Vol. 162, No. 3, pp. D124–D128, 2015.

Zhong, L., Xuehu, M., Sifang, W., Mingzhe, W., and Xiaonan, L., “Effects of Surface Free Energy and Nanostructures on Dropwise Condensation,” Chemical Engineering Journal, Vol. 156, No. 3, pp. 546–552, 2010.

Shirtcliffe, N. J., McHale, G., Newton, M. I., and Zhang, Y., “Superhydrophobic Copper Tubes with Possible Flow Enhancement and Drag Reduction,” ACS Applied Materials and Interfaces, Vol. 1, No. 6, pp. 1316–1323, 2009.

Crick, C. R., Gibbins, J. A., and Parkin, I. P., “Superhydrophobic Polymer-Coated Copper-Mesh; Membranes for Highly Efficient Oil–Water Separation,” Journal of Materials Chemistry A, Vol. 1, No. 19, pp. 5943–5948, 2013.

Lee, J. M. and Ko, J. S., “Effects of a Micro Pattern on Cu Alloy Electrodeposition and Its Application as an Oil Detector,” Micro and Nano Systems Letters, Vol. 4, No. 9, pp. 1–8, 2016. (DOI: 10.1186/s40486-016-0034-6)

Lu, Y., Ren, Z., Yuan, H., Wang, Z., Yu, B., and Chen, J., “Atmospheric-Pressure Microplasma as Anode for Rapid and Simple Electrochemical Deposition of Copper and Cuprous Oxide Nanostructures,” RSC Advances, Vol. 5, No. 77, pp. 62619–62623, 2015.

Yu, G., Hu, X., Liu, D., Sun, D., Li, J., et al., “Electrodeposition of Submicron/Nanoscale Cu2O/Cu Junctions in an Ultrathin CuSO4 Solution Layer,” Journal of Electroanalytical Chemistry, Vol. 638, No. 2, pp. 225–230, 2010.

Šupicová, M., Rozik, R., Trnkova, L., Orináková, R., and Galova, M., “Influence of Boric Acid on the Electrochemical Deposition of Ni,” Journal of Solid State Electrochemistry, Vol. 10, No. 2, pp. 61–68, 2006.

Cassie, A. B. D. and Baxter, S., “Wettability of Porous Surfaces,” Transactions of the Faraday Society, Vol. 40, pp. 546–551, 1944.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, J.M., Ko, J.S. Formation of microstructure by copper-cuprous co-electrodeposition using stirring and boric acid addition. Int. J. Precis. Eng. Manuf. 18, 871–877 (2017). https://doi.org/10.1007/s12541-017-0103-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-017-0103-7