Abstract

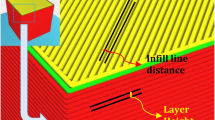

3D printing technologies have gotten an attention as a viable option for future manufacturing. Among them, FDM is the most popular one because it is inexpensive and can process with multiples materials. Layered surface, that has high roughness, is obtained with the technology due to layer-by-layer based process. This result highly decreases value of the final product. Various methods for postprocessing were proposed to achieve fine surface. Among them, vapor smoothing process is one of powerful methods because of its cost-effectiveness and usefulness. However, this process could affect mechanical property of the printed structure. In this study, we investigated the effect of the vapor smoothing technique with 3D printed structures in terms of thermal-dependent mechanical property. ABS structure was fabricated with FDM and applied into the post-processing. Then, temperature-dependent storage modulus and tan δ of the structure were measured with dynamic mechanical analysis (DMA) in the variation of amount of acetone. The results showed that the process highly affects to the thermal stability. Below 50°C, any differences were not observed. However, lower modulus and higher tan δ were shown in the higher temperature. This experiment provides very useful data for FEM simulation to predict mechanical property of a 3D printed structure.

Similar content being viewed by others

References

Gao, W., Zhang, Y., Ramanujan, D., Ramani, K., Chen, Y., et al., “The Status, Challenges, and Future of Additive Manufacturing in Engineering,” Computer-Aided Design, Vol. 69, pp. 65–89, 2015.

Ko, H., Moon, S. K., and Hwang, J., “Design for Additive Manufacturing in Customized Products,” Int. J. Precis. Eng. Manuf., Vol. 16, No. 11, pp. 2369–2375, 2015.

Jo, K.-H., Jeong, Y.-S., Lee, J.-H., and Lee, S.-H., “A Study of Post-Processing Methods for Improving the Tightness of a Part Fabricated by Fused Deposition Modeling,” Int. J. Precis. Eng. Manuf., Vol. 17, No. 11, pp. 1541–1546, 2016.

Kim, H.-C., Lee, I.-H., and Ko, T. J., “3D Tool Path Generation for Micro-Abrasive Jet Machining on 3D Curved Surface,” Int. J. Precis. Eng. Manuf., Vol. 14, No. 9, pp. 1519–1525, 2013.

Kuo, C.-C. and Mao, R.-C., “Development of a Precision Surface Polishing System for Parts Fabricated by Fused Deposition Modeling,” Materials and Manufacturing Processes, Vol. 31, No. 8, pp. 1113–1118, 2016.

Garg, A., Bhattacharya, A., and Batish, A., “On Surface Finish and Dimensional Accuracy of FDM Parts after Cold Vapor Treatment,” Materials and Manufacturing Processes, Vol. 31, No. 4, pp. 522–529, 2016.

Chohan, J. S., Singh, R., and Boparai, K. S., “Mathematical Modeling of Surface Roughness for Vapour Processing of ABS Parts Fabricated with Fused Deposition Modeling” Journal of Manufacturing Processes, Vol. 24, Part 1, pp. 161–169, 2016.

Belter, J. T., and Dollar, A. M., “Strengthening of 3D Printed Fused Deposition Manufactured Parts Using the Fill Compositing Technique,” PloS One, Vol. 10. No. 4. e0122915

Eujin Pei, D., Melenka, G. W., Schofield, J. S., Dawson, M. R., and Carey, J. P., “Evaluation of Dimensional Accuracy and Material Properties of the Makerbot 3D Desktop Printer,” Rapid Prototyping Journal, Vol. 21, No. 5, pp. 618–627, 2015.

Cantrell, J., Rohde, S., Damiani, D., Gurnani, R., DiSandro, L., et al., “Experimental Characterization of the Mechanical Properties of 3D Printed ABS and Polycarbonate Parts,” in: Advancement of Optical Methods in Experimental Mechanics, Yoshida, S., Lamberti, L., Sciammarella, C., (Eds.), Springer, Vol. 3, pp. 89–105, 2017.

Lyu, M.-Y. and Choi, T.G., “Research Trends in Polymer Materials for Use in Lightweight Vehicles,” Int. J. Precis. Eng. Manuf., Vol. 16, No. 1, pp. 213–220, 2015.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, SU., Han, J. & Kang, HW. Temperature-dependent mechanical properties of ABS parts fabricated by fused deposition modeling and vapor smoothing. Int. J. Precis. Eng. Manuf. 18, 763–769 (2017). https://doi.org/10.1007/s12541-017-0091-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-017-0091-7