Abstract

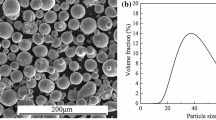

Wide-gap defects repair of Mar-M247 superalloy was investigated by utilizing powder metallurgy. New interlayer alloy with relatively high content of B and Zr was designed based on the isothermal solidification principle. The interlayer alloy is characterized by relative low melting temperature (1100 °C), and the contact angle of interlayer on the Mar-M247 substrate is ~ 70º. Based on the thermodynamic calculation results, the mixture powders with 80 wt% substrate powder and 20 wt% interlayer alloy powder was used as a filler to repair the wide gap with width of 2 mm. After repaired at 1230 °C for 2 h, near-fully dense gap was obtained. MC-type carbides, MB2-type boride, M3B2-type boride and Ni5(Zr,Hf)-type intermetallic were observed in the liquid zone. After post-weld heat treatment, the block borides, chain carbides and eutectic are successfully removed, and the tensile strength of the bonding zone is close to that of the Mar-M247 superalloy.

Graphical abstract

Similar content being viewed by others

Data and code Availability

The datasets used and/or analyzed during the current study are available from the corresponding author (Ye Liu) on reasonable request.

References

H.S. Whitesell, R.A. Overfelt, Mater. Sci. Eng. A 318, 264 (2001). https://doi.org/10.1016/S0921-5093(01)01264-3

H.Y. Bor, C.G. Chao, C.Y. Ma, Scripta Mater. 38, 329 (1997). https://doi.org/10.1016/S1359-6462(97)00444-2

M.V. Nathal, R.D. Maier, L.J. Ebert, Metall. Mater. Trans. A 13, 1775 (1982). https://doi.org/10.1007/BF02647833

J. Chen, J.H. Lee, C.Y. Jo, S.J. Choe, Y.T. Lee, Mater. Sci. Eng. A 247, 113 (1998). https://doi.org/10.1016/S0921-5093(97)00761-2

S. Milenkovic, I. Sabirov, J. LLorca, Mater. Lett. 73, 216 (2012). https://doi.org/10.1016/j.matlet.2012.01.028

R. Darolia, Int. Mater. Rev. 64, 355 (2019). https://doi.org/10.1080/09506608.2018.1516713

S. Mokadem, C. Bezencon, A. Hauert, A. Jacot, W. Kurz, Metall. Mater. Trans. A 38, 1500 (2007). https://doi.org/10.1007/s11661-007-9172-z

J.H.G. Mattheij, Mater. Sci. Technol. 1, 608 (1985). https://doi.org/10.1179/mst.1985.1.8.608

Z. Wang, H. Qiang, J. Wang, L. Duan, Propell. Explos. Pyrot. 47, e202200046 (2022). https://doi.org/10.1002/prep.202200046

Y. Zeng, L. Li, W. Huang, Z. Zhao, W. Yang, Z. Yue, Int. J. Mech. Sci. 221, 107173 (2022). https://doi.org/10.1016/j.ijmecsci.2022.107173

X. Huang, W. Miglietti, J. Eng. Gas Turbines Power 134, 010801 (2012). https://doi.org/10.1115/1.4003962

E.P. Hinchy, D. Barron, M.J. Pomeroy, D.A. Tanner, J. Alloys Compd. 857, 157560 (2021). https://doi.org/10.1016/j.jallcom.2020.157560

G. Liu, D. Du, K. Wang, Z. Pu, D. Zhang, B. Chang, Mater. Sci. Eng. A 808, 140911 (2021). https://doi.org/10.1016/j.msea.2021.140911

Y. Ye, G. Zou, W. Long, Q. Jia, H. Bai, A. Wu, L. Liu, Sci. Technol. Weld. Joi. 24, 52 (2019). https://doi.org/10.1080/13621718.2018.1477546

T. Kalfhaus, H. Schaar, F. Thaler, B. Ruttert, D. Sebold, J. Frenzel, I. Steinbach, W. Theisen, O. Guillon, T.W. Clyne, R. Vassen, Surf. Coat. Tech. 405, 126494 (2021). https://doi.org/10.1016/j.surfcoat.2020.126494

H. Chen, J.C. Lippold, J. Vollbrecht, R. Grylls, D. Liu, J. Laser Appl. 34, 012008 (2022). https://doi.org/10.2351/7.0000553

Z.P. Zhang, J.D. Liu, K.Q. Qiu, Y.Y. Huang, J.G. Li, X.G. Wang, J.L. Liu, M. Wang, M.K. Zou, Y.Z. Zhou, Met. Mater. Int. 29, 444 (2023). https://doi.org/10.1007/s12540-022-01223-7

H. Assadi, A. Shirzadi, E. Wallach, Acta Mater. 49, 31 (2001). https://doi.org/10.1016/S1359-6454(00)00307-4

M. Pouranvari, A. Ekrami, A.H. Kokabi, Mater. Sci. Eng. A 568, 76 (2013). https://doi.org/10.1016/j.msea.2013.01.029

M. Pouranvari, A. Ekrami, A.H. Kokabi, J. Alloys Compd. 469, 270 (2009). https://doi.org/10.1016/j.jallcom.2008.01.101

J. Cao, Y.F. Wang, X.G. Song, C. Li, J.C. Feng, Mater. Sci. Eng. A 590, 1 (2014). https://doi.org/10.1016/j.msea.2013.10.013

B. Zhang, G. Sheng, Y. Jiao, Z. Gao, X. Gong, H. Fan, J. Zhong, J. Alloys Compd. 695, 3202 (2017). https://doi.org/10.1016/j.jallcom.2016.11.306

M. Pouranvari, A. Ekrami, A.H. Kokabi, Mater. Sci. Eng. A 490, 229 (2008). https://doi.org/10.1016/j.msea.2008.01.032

J.K. Kim, H.J. Park, D.N. Shim, D.J. Kim, J. Manuf. Process. 30, 208 (2017). https://doi.org/10.1016/j.jmapro.2017.09.024

N.C. Sheng, J.D. Liu, T. Jin, X.F. Sun, Z.Q. Hu, Metall. Mater. Trans. A 44, 1793 (2013). https://doi.org/10.1007/s11661-012-1540-7

R. Bakhtiari, A. Ekram, T.I. Khan, Mater. Sci. Eng. A 546, 291 (2012). https://doi.org/10.1016/j.msea.2012.03.073

R.K. Saha, T.I. Khan, J. Mater. Sci. 42, 9187 (2007). https://doi.org/10.1007/s10853-007-1922-1

M.S. Kenevisi, S.M. Mousavi, M. Alaei, Mech. Mater. 64, 69 (2013). https://doi.org/10.1016/j.mechmat.2013.04.011

A.T. Olanipekun, N.B. Maledi, P.M. Mashinini, Powder Metall. 63, 254 (2020). https://doi.org/10.1080/00325899.2020.1807712

O.A. Ojo, J. Mater. Sci. 47, 1598 (2012). https://doi.org/10.1007/s10853-011-6176-2

S.Y. Wang, Y. Sun, C.Y. Cui, X.F. Sun, Y.Z. Zhou, Y.M. Ma, H.L. An, J. Mater. Sci. Technol. 80, 244 (2021). https://doi.org/10.1016/j.jmst.2020.05.078

Y. Ye, G. Zou, W. Long, H. Bai, A. Wu, L. Liu, Y. Zhou, J. Alloys Compd. 748, 26 (2018). https://doi.org/10.1016/j.jallcom.2018.02.343

W. Li, T. Jin, X.F. Sun, Y. Guo, H.R. Guan, Z.Q. Hu, Scripta Mater. 48, 1283 (2003). https://doi.org/10.1016/S1359-6462(03)00045-9

G. Wang, Y. Sun, X. Wang, J. Liu, J. Liu, J. Li, X. Sun, J. Yu, Y. Zhou, T. Jin, X. Sun, X. Sun, J. Mater. Sci. Technol. 33, 1219 (2017). https://doi.org/10.1016/j.jmst.2017.01.027

O.J. Adebajo, O.A. Ojo, Metall. Mater. Trans. A 48, 26 (2017). https://doi.org/10.1007/s11661-016-3837-4

Y.-L. Tsai, S.-F. Wang, H.-Y. Bor, Y.-F. Hsu, Mater. Sci. Eng. A 571, 155 (2013). https://doi.org/10.1016/j.msea.2013.02.002

A.K. Jena, M.C. Chturvedi, J. Mater. Sci. 19, 3121 (1984). https://doi.org/10.1007/BF00549796

C.Z. Zhu, R. Zhang, C.Y. Cui, Y.Z. Zhou, Y. Yuan, Z.S. Yu, X.F. Sun, Metall. Mater. Trans. A 52, 108 (2021). https://doi.org/10.1007/s11661-020-06081-9

B. Yin, G. Xie, L.H. Lou, J. Zhang, J. Alloys Compd. 829, 154440 (2020). https://doi.org/10.1016/j.jallcom.2020.154440

J.-O. Andersson, T. Helander, L. Höglund, P. Shi, B. Sundman, Calphad 26, 273 (2002). https://doi.org/10.1016/S0364-5916(02)00037-8

T. Henhoeffer, X. Huang, S. Yandt, P. Au, J. Eng. Gas Turbines Power. 133, 092101 (2011). https://doi.org/10.1115/1.4002824

C.Y. Su, W.C. Lih, C.P. Chou, H.C. Tsai, J. Mater. Process. Tech. 115, 326 (2001). https://doi.org/10.1016/S0924-0136(01)00831-7

H. Deng, Y. Chen, Y. Jia, Y. Pang, T. Zhang, S. Wang, L. Yin, J. Manuf. Process. 64, 379 (2021). https://doi.org/10.1016/j.jmapro.2021.01.024

Y. Chen, Y. Mao, W. Lu, P. He, Opt. Laser Technol. 91, 197 (2017). https://doi.org/10.1016/j.optlastec.2016.12.028

G.M. Karthik, H.S. Kim, Met. Mater. Int. 27, 1 (2021). https://doi.org/10.1007/s12540-020-00931-2

Q. Zhu, J. Chen, G. Gou, H. Chen, P. Li, J. Mater. Process. Tech. 246, 267 (2017). https://doi.org/10.1016/j.jmatprotec.2017.03.022

J.-H. Park, G.B. Bang, K.-A. Lee, Y. Son, Y.H. Song, B.-S. Lee, W.R. Kim, H.G. Kim, Met. Mater. Int. 28, 2836 (2022). https://doi.org/10.1007/s12540-022-01169-w

M. Kumaran, V. Senthilkumar, Met. Mater. Int. 29, 467 (2023). https://doi.org/10.1007/s12540-022-01225-5

Y. Lee, E.S. Kim, S. Park, J.M. Park, J.B. Seol, H.S. Kim, T. Lee, H. Sung, J.G. Kim, Met. Mater. Int. 28, 197 (2022). https://doi.org/10.1007/s12540-021-01081-9

A.H. Nassajpour-Esfahani, R. Emadi, A. Alhaji, A. Bahrami, M.R. Haftbaradaran-Esfahani, J. Alloys Compd. 830, 154588 (2020). https://doi.org/10.1016/j.jallcom.2020.154588

A.S. Namini, M.S. Asl, S.A. Delbari, Met. Mater. Int. 27, 1092 (2021). https://doi.org/10.1007/s12540-019-00469-y

M.M. Dewidar, H.-C. Yoon, J.K. Lim, Met. Mater. Int. 12, 193 (2006). https://doi.org/10.1007/BF03027531

R. Baldan, R.L.P. da Rocha, R.B. Tomasiello, C.A. Nunes, A.M. da Silva Costa, M.J.R. Barboza, G.C. Coelho, R. Rosenthal, J. Mater. Eng. Perform. 22, 2574 (2013). https://doi.org/10.1007/s11665-013-0565-4

Acknowledgements

This work is supported by the fund of State Key Laboratory of Long-life High Temperature Materials (DTCC28EE200792), National Natural Science Foundation of China (51974029, 52074032, 52101152), Natural Science and Technology Major Project (2017-VI-0014-0086), Fundamental Research Funds for the Central Universities (FRF-BD-20-23 A, FRF-GF-20-27B), 111 project (B170003), Provincial Natural Science Foundation of Hunan (2022JJ40438, 2022JJ30564) and the 2022 opening subject of State Key Laboratory of Powder Metallurgy.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest or competing interests.

Informed Consent

for publication of this paper was obtained from all authors.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Xiufang Gong and Yankang Yu have contributed equally to this work.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gong, X., Yu, Y., Wang, T. et al. Wide-Gap Repair of Mar-M247 Superalloy via Powder Metallurgy Route. Met. Mater. Int. 29, 3286–3297 (2023). https://doi.org/10.1007/s12540-023-01443-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-023-01443-5