Abstract

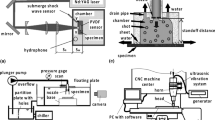

Nanostructured materials exhibit superior properties with respect to their bulk counterpart. Recently, a new processing method for surface nanostructuring of metallic materials called surface mechanical impact treatment (SMIT) was developed. In this study, the surface microstructural features due to the refinement process of AISI 316L stainless steel by means of SMIT and subsequent mechanical performance were investigated. The effects of SMIT processing parameters, i.e. ball size and treatment duration, were studied in terms of microstructural evolutions using X-ray diffraction, transmission electron microscopy, optical microscopy, and field emission scanning electron microscopy analyses, and mechanical properties through hardness and tensile tests. A gradient nanostructured surface layer was successfully formed on the surface of the treated samples. The mean grain size was measured to be ~ 20 nm in the topmost surface layer and increased with increasing depth. Microstructural examinations showed that the twins and their intersections (rhombic blocks) formed in the surface layers. It was found that the mechanical performance of the treated samples is effectively enhanced. The surface hardness of the treated samples increased about 3 times while the yield strength of the samples increased with increasing SMIT time and size of the ball up to 2.5 times. The grain refinement mechanisms, mechanical properties, and fracture behavior were subsequently analyzed and discussed.

Graphical Abstract

Similar content being viewed by others

Abbreviations

- A:

-

Zener anisotropy

- b:

-

Burgers vector

- C:

-

Elastic stiffness coefficient

- D:

-

Grain size

- d:

-

Diameter of the ball

- G:

-

Shear modulus

- I:

-

Intensity

- K111ω0 :

-

Proportionality constant

- fα ' :

-

Volume fraction of α′-martensite

- R:

-

Reliability factor

- t:

-

Time

- α:

-

Stacking fault probability

- α0 :

-

Unit cell edge dimension

- ץ:

-

Stacking fault energy

- ρ:

-

Dislocation density

- ε:

-

Lattice microstrain

- AISI:

-

American Iron and Steel Institute

- DIM:

-

Deformation induced martensite

- FESEM:

-

Field emission scanning electron microscopy

- FCC:

-

Face centered cubic

- HCP:

-

Hexagonal closest packed

- OM:

-

Optical microscopy

- SAED:

-

Selected area electron diffraction

- SF:

-

Stacking fault

- SFE:

-

Stacking fault energy

- SFP:

-

Stacking fault probability

- SFT:

-

Stacking fault tetrahedra

- SMAT:

-

Surface mechanical attrition treatment

- SMGT:

-

Surface mechanical grinding treatment

- SMIT:

-

Surface mechanical impact treatment

- SMRT:

-

Surface mechanical rolling treatment

- SPD:

-

Severe plastic deformation

- TEM:

-

Transmission electron microscopy

- TRIP:

-

Transformation induced plasticity

- UIP:

-

Ultrasonic impact peening

- UIT:

-

Ultrasonic impact treatment

- XRD:

-

X-ray diffraction

References

K.S. Kumar, H. Van Swygenhoven, S. Suresh, Acta Mater. 51, 5743–5774 (2003). https://doi.org/10.1016/j.actamat.2003.08.032

M.A. Meyers, A. Mishra, D.J. Benson, Prog. Mater. Sci. 51, 427–556 (2006). https://doi.org/10.1016/j.pmatsci.2005.08.003

N.A. Dan Liu, D. Liu, X. Zhang, C. Liu, Mater. Sci. Eng. A 726, 69–81 (2018). https://doi.org/10.1016/j.msea.2018.04.033

A.M. Hodge, Y.M. Wang, T.W. Barbee Jr., Mater. Sci. Eng. A 429, 272–276 (2006). https://doi.org/10.1016/j.msea.2006.05.109

A. Zaffora, F. Di Franco, M. Santamaria, Curr. Opin. Electrochem. 29, 100760 (2021). https://doi.org/10.1016/j.coelec.2021.100760

L. Ceschini, C. Chiavari, E. Lanzoni, C. Martini, Mater. Design 38, 154–160 (2012). https://doi.org/10.1016/j.matdes.2012.02.019

S. Bagherifard, S. Slawik, I. Fernández-pariente, C. Pauly, F. Mücklich, M. Guagliano, Mater. Design 102, 68–77 (2016). https://doi.org/10.1016/j.matdes.2016.03.162

Y.G. Liu, M.Q. Li, H.J. Liu, Mater. Charact. 123, 83–90 (2017). https://doi.org/10.1016/j.matchar.2016.11.020

C.S. Montross, T. Wei, L. Ye, G. Clark, Y.-W. Mai, Int. J. Fatigue 24, 1021–1036 (2002). https://doi.org/10.1016/S0142-1123(02)00022-1

S. Kalainathan, S. Sathyajith, S. Swaroop, Opt. Laser. Eng. 50, 1740–1745 (2012). https://doi.org/10.1016/j.optlaseng.2012.07.007

S. Bahl, S. Suwas, T. Ungàr, K. Chatterjee, Acta Mater. 122, 138–151 (2017). https://doi.org/10.1016/j.actamat.2016.09.041

A. Heydari, R. Miresmaeili, S. Bagherifard, M. Guagliano, M. Aliofkhazraei, Mater. Design 116, 365–373 (2017). https://doi.org/10.1016/j.matdes.2016.12.045

T.O. Olumide, J. Lu, Nano Mater. Sci. 2, 3 (2020). https://doi.org/10.1016/j.nanoms.2020.04.002

W.L. Li, N.R. Tao, K. Lu, Scripta Mater. 59, 546–549 (2008). https://doi.org/10.1016/j.scriptamat.2008.05.003

Y.Z. Zhang, J.J. Wang, N.R. Tao, J. Mater. Sci. Technol. 36, 65 (2019). https://doi.org/10.1016/j.jmst.2019.02.008

H.W. Huang, Z.B. Wang, J. Lu, K. Lu, Acta Mater. 87, 150–160 (2015). https://doi.org/10.1016/j.actamat.2014.12.057

Y. Ye, S.-Z. Kure-Chu, Z. Sun, X. Li, H. Wang, G. Tang, Mater. Design 149, 214–227 (2018). https://doi.org/10.1016/j.matdes.2018.04.027

M. Jamalian, D.P. Field, J. Mater. Sci. Technol. 36, 45–49 (2020). https://doi.org/10.1016/j.jmst.2019.06.013

M. Dehghan, R. Miresmaeili, M. Askari-Paykani, H.R. Shahverdi, Met. Mater. Int. 28, 1232–1245 (2022). https://doi.org/10.1007/s12540-021-01007-5

T. Roland, D. Retraint, K. Lu, J. Lu, Scripta Mater. 54, 1949–1954 (2006). https://doi.org/10.1016/j.scriptamat.2006.01.049

F.K. Yan, G.Z. Liu, N.R. Tao, K. Lu, Acta Mater. 60, 1059–1071 (2012). https://doi.org/10.1016/j.actamat.2011.11.009

R. Peng, L. Fu, L. Zhou, Appl. Surf. Sci. 388, 406–411 (2016). https://doi.org/10.1016/j.apsusc.2015.12.103

Z.D. Wang, G.F. Sun, Y. Lu, M.Z. Chen, K.D. Bi, Z.H. Ni, Surf. Coat. Tech. 385, 125403 (2020). https://doi.org/10.1016/j.surfcoat.2020.125403

S.M. Hassani-gangaraj, K.S. Cho, H.L. Voigt, M. Guagliano, C.A. Schuh, Acta Mater. 97, 105–115 (2015). https://doi.org/10.1016/j.actamat.2015.06.054

Y. Liu, M. Li, Mater. Sci. Eng. A 669, 7–13 (2016). https://doi.org/10.1016/j.msea.2016.05.088

R. Madhavan, S. Suwas, Acta Mater. 121, 46–58 (2016). https://doi.org/10.1016/j.actamat.2016.08.036

W.H.S. Lou, Y. Li, L. Zhou, X. Nie, G. He, Y. Li, L. Yuqin, H. Weifeng, Mater. Design 104, 320–326 (2016). https://doi.org/10.1016/j.matdes.2016.05.028

S.M. Dasharath, S. Mula, Mater. Design 99, 552-564 (2016). https://doi.org/10.1016/j.matdes.2016.03.095

W.S. Zhao, N.R. Tao, J.Y. Guo, Q.H. Lu, K. Lu, Scripta Mater. 53, 745–749 (2005). https://doi.org/10.1016/j.scriptamat.2005.05.022

S. Scheriau, Z. Zhang, S. Kleber, R. Pippan, Mater. Sci. Eng. A 528, 2776–2786 (2011). https://doi.org/10.1016/j.msea.2010.12.023

M. Jayalakshmi, P. Huilgol, B. Ramachandra, K.U. Bhat, Surf. Coat. Tech. 344, 295–302 (2018). https://doi.org/10.1016/j.surfcoat.2018.03.028

B. Schuh, R. Pippan, A. Hohenwarter, Mater. Sci. Eng. A 748, 379–385 (2019). https://doi.org/10.1016/j.msea.2019.01.073

H.Q. Sun, Y.-N. Shi, M.-X. Zhang, K. Lu, Acta Mater. 55, 975–982 (2007). https://doi.org/10.1016/j.actamat.2006.09.018

A.K. Agrawal, A. Singh, A. Vivek, S. Hansen, G. Daehn, Mater. Lett. 22, 50-53 (2018). https://doi.org/10.1016/j.matlet.2018.04.044

R.D.K. Misra, V.S.A. Challa, P.K.C. Venkatsurya, Y.F. Shen, M.C. Somani, L.P. Karjalainen, Acta Mater. 84, 339–348 (2015). https://doi.org/10.1016/j.actamat.2014.10.038

S.J. Wang, T. Jozaghi, I. Karaman, R. Arroyave, Y.I. Chumlyakov, Mater. Sci. Eng. A 694, 121-131 (2017). https://doi.org/10.1016/j.msea.2017.03.073

Z. Fan, H. Xu, D. Li, L. Zhang, L. Liao, Procedia Eng. 27, 1718–1722 (2012). https://doi.org/10.1016/j.proeng.2011.12.641

E. Maleki, N. Maleki, A. Fattahi, O. Unal, M. Guagliano, S. Bagherifard, Surf. Coat. Tech. 405, 126729 (2021). https://doi.org/10.1016/j.surfcoat.2020.126729

G.K. Williamson, W.H. Hall, Acta Metall. 1, 22–31 (1953). https://doi.org/10.1016/0001-6160(53)90006-6

R.E. Schramm, R.P. Reed, Metall. Trans. A 6, 1345–1351 (1975)

J.-E. Jin, Y.-K. Lee, Acta Mater. 60, 1680–1688 (2012). https://doi.org/10.1016/j.actamat.2011.12.004

J. Talonen, H. Hänninen, Acta Mater. 55, 6108–6118 (2007). https://doi.org/10.1016/j.actamat.2007.07.015

K. Kumar, A. Pooleery, K. Madhusoodanan, R.N. Singh, J.K. Chakravartty, B.K. Dutta, R.K. Sinha, Procedia Engineer. 86, 899–909 (2014). https://doi.org/10.1016/j.proeng.2014.11.112

J.W. Wang, S. Narayanan, J. Yu Huang, Z. Zhang, T. Zhu, S.X. Mao, Nat. Commun. 4, 2340 (2013). https://doi.org/10.1038/ncomms3340

M.H. Loretto, P.J. Phillips, M.J. Mills, Scripta Mater. 94, 1–4 (2015). https://doi.org/10.1016/j.scriptamat.2014.07.020

B.N Singh, N.M Ghoniem, H Trinkaus, J. Nucl. Mater. 307–311, 159–170 (2002). https://doi.org/10.1016/S0022-3115(02)01095-4

R. Schäublin, Z. Yao, N. Baluc, M. Victoria, Philos. Mag. 85, 769-777 (2005). https://doi.org/10.1080/14786430412331319929

J. Silcox, P.B. Hirsch, Philos. Mag. A 4, 72-89 (1959). https://doi.org/10.1080/14786435908238228

H. Wang, D.S. Xu, R. Yang, P. Veyssie, Acta Mater. 59, 19–29 (2011). https://doi.org/10.1016/j.actamat.2010.07.045

M.H. Loretto, A. Pavey, Philos. Mag. A 17, 553-559 (1968). https://doi.org/10.1080/14786436808217742

Q. Wang, Q. Bai, J. Chen, Y. Guo, W. Xie, Appl. Surf. Sci. 355, 1153–1160 (2015). https://doi.org/10.1016/j.apsusc.2015.06.176

M. Moallemi, A. Kermanpur, A. Naja, A. Rezaee, H.S. Baghbadorani, P.D. Nezhadfar, Mater. Sci. Eng. A 653, 147–152 (2016). https://doi.org/10.1016/j.msea.2015.12.006

S. Vercammen, B. Blanpain, Acta Mater. 52, 2005–2012 (2012). https://doi.org/10.1016/j.actamat.2003.12.040

D. Canadinc, H. Sehitoglu, H.J. Maier, Y.I. Chumlyakov, Acta Mater. 53, 1831–1842 (2005). https://doi.org/10.1016/j.actamat.2004.12.033

H.J. Bae, K.K. Ko, M. Ishtiaq, J.G. Kim, H. Sung, J.B. Seol, J. Mater. Sci. Technol. 115, 177–188 (2022). https://doi.org/10.1016/j.jmst.2021.11.027

M.A. Vasylyev, B.N. Mordyuk, S.I. Sidorenko, S.M. Voloshko, A.P. Burmak, Surf. Coat. Tech. 343, 57–68 (2018). https://doi.org/10.1016/j.surfcoat.2017.11.019

V. Azar, B. Hashemi, M.R. Yazdi, Surf. Coat. Tech. 204, 3546–3551 (2010). https://doi.org/10.1016/j.surfcoat.2010.04.015

P. Peyre, X. Scherpereel, L. Berthe, C. Carboni, R. Fabbro, G. Béranger, C. Lemaitre, Mater. Sci. Eng. A 280, 294–302 (2000). https://doi.org/10.1016/S0921-5093(99)00698-X

X.H. Chen, J. Lu, L. Lu, K. Lu, Scripta Mater. 52, 1039–1044 (2005). https://doi.org/10.1016/j.scriptamat.2005.01.023

K. Lu, J. Lu, Mater. Sci. Eng. A 357-377, 38–45 (2004). https://doi.org/10.1016/j.msea.2003.10.261

P. Zhang, J. Lindemann, Scripta Mater. 52, 485–490 (2005). https://doi.org/10.1016/j.scriptamat.2004.11.003

S. Bagherifard, I.F. Pariente, R. Ghelichi, M. Guagliano, Procedia Eng. 2, 1683–1690 (2010). https://doi.org/10.1016/j.proeng.2010.03.181

Y.F. Shen, X.X. Li, X. Sun, Y.D. Wang, L. Zuo, Mater. Sci. Eng. A 552, 514–522 (2012). https://doi.org/10.1016/j.msea.2012.05.080

K. Datta, R. Delhez, P.M. Bronsveld, J. Beyer, H.J.M. Geijselaers, J. Post, Acta Mater. 57, 3321–3326 (2009). https://doi.org/10.1016/j.actamat.2009.03.039

J.A. Venables, Philos. Mag. A 7, 35–44 (1962). https://doi.org/10.1080/14786436208201856

Z. Guo, Y. Rong, S. Chen, T.Y. Hsu, Scripta Mater. 41, 153–158 (1999). https://doi.org/10.1016/S1359-6462(99)00134-7

T.Y. Hsu, X. Zuyao, Mater. Sci. Eng. A 273-275, 494–497 (1999). https://doi.org/10.1016/S0921-5093(99)00386-X

A. Etienne, B. Radiguet, C. Genevois, J.-M. Le Breton, R. Valiev, P. Pareige, Mater. Sci. Eng. A 527, 5805–5810 (2010). https://doi.org/10.1016/j.msea.2010.05.049

C. Ye, S. Suslov, D. Lin, G.J. Cheng, Philos. Mag. 92, 1369-1389 (2012). doi:https://doi.org/10.1080/14786435.2011.645899.

K.P. Staudhammer, L.E. Murr, S.S. Hecker, Acta Mater. 31, 267–274 (1983). https://doi.org/10.1016/0001-6160(83)90103-7

B.N. Mordyuk, Y.V. Milman, M.O. Ie, G.I. Prokopenko, V.V. Silberschmidt, M.I. Danylenko, A.V. Kotko, Surf. Coat. Tech. 202, 4875–4883 (2008). https://doi.org/10.1016/j.surfcoat.2008.04.080

B.N. Mordyuk, G.I. Prokopenko, M.A. Vasylyev, M.O. Iefimov, Mater. Sci. Eng. A 458, 253–261 (2007). https://doi.org/10.1016/j.msea.2006.12.049

Y.F. Shen, N. Jia, Y.D. Wang, X. Sun, L. Zuo, D. Raabe, Acta Mater. 97, 305–315 (2015). https://doi.org/10.1016/j.actamat.2015.06.053

Y. Matsukawa, Y.N. Osetsky, R.E. Stoller, S.J. Zinkle, Philos. Mag. 88, 581-597 (2008). https://doi.org/10.1080/14786430801898644

Y. Matsukawa, Y.N. Osetsky, R.E. Stoller, S.J. Zinkle, J. Nucl. Mater. 351, 285–294 (2006). https://doi.org/10.1016/j.jnucmat.2006.02.003

J.S. Robach, I.M. Robertson, H.-J. Lee, B.D. Wirth, Acta Mater. 54, 1679–1690 (2006). https://doi.org/10.1016/j.actamat.2005.11.038

Y. Matsukawa, S.J. Zinkle, J. Nucl. Mater. 329-333, 919–923 (2004). https://doi.org/10.1016/j.jnucmat.2004.04.069

M. Briceño, J. Kacher, I.M. Robertson, J. Nucl. Mater. 433, 390–396 (2013). https://doi.org/10.1016/j.jnucmat.2012.10.004

Acknowledgements

The authors wish to extend their deepest gratitude to Dr. Farhad Farzan for assisting in the design and manufacturing of the SMIT setup.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rostami, M., Miresmaeili, R. & Heydari Astaraee, A. Investigation of Surface Nanostructuring, Mechanical Performance and Deformation Mechanisms of AISI 316L Stainless Steel Treated by Surface Mechanical Impact Treatment. Met. Mater. Int. 29, 948–967 (2023). https://doi.org/10.1007/s12540-022-01286-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01286-6