Abstract

Solid-state bonding of heterogeneous materials is one of the effective ways to achieve light weight. An extrusion forming process for Mg/Al thickness-oriented bonding sheet was carried out. Due to triaxial compressive stress in the extrusion container, the AZ31 and AA6061 billets were deformed and the bonding and forming of Mg/Al thickness-oriented sheet can be realized by this method. The observation results of the bonding position by using XRD, SEM and EDS showed that: at the forming temperature with 360–420 °C, it had a good bonding interface, and the width of the transition layer increased with the increase of the forming temperature. The presence of brittle intermetallic compounds in the transition layer indicated that metallurgical bonding had occurred at the interface. Considering all factors comprehensively, when the forming temperature was 390 °C, the bonding quality was appropriate. Its tensile-shear strength was 42 MPa, the width of the interface transition layer was about 10 μm, and the microhardness was about 164.3 HV. This method provided scientific guidance and technical reserves for green forming of Mg/Al sheets.

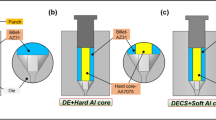

Graphic Abstract

Similar content being viewed by others

References

Z.R. Zeng, N. Stanford, C.H.J. Davies, J.F. Nie, N. Birbilis, Int. Mater. Rev. 64, 27 (2019)

Y. Meng, Q. Chen, S. Sugiyama, J. Yanagimoto, J. Mater. Process. Tech. 247, 192 (2017)

M.C. Paulisch, M. Lentz, H. Wemme, A. Andrich, I. Driehorst, W. Reimers, J. Mater. Process. Tech. 233, 68 (2016)

B. Feng, Y.C. Xin, Z. Sun, H.H. Yu, J. Wang, Q. Liu, Mater. Sci. Eng. A 704, 173 (2017)

E. Priel, Z. Ungarish, N.U. Navi, J. Mater. Process. Tech. 236, 103 (2016)

K. Sheng, L.W. Lu, Y. Xiang, M. Ma, Z.Q. Wu, J. Magnes. Alloy. 7, 717 (2019)

L.M. Liu, D.X. Ren, F. Liu, Materials 7, 3735 (2014)

J.F. Song, J. She, D.L. Chen, F.S. Pan, J. Magnes. Alloy. 8, 1 (2020)

Y. Wu, B. Feng, Y.C. Xin, R. Hong, H.H. Yu, Q. Liu, Mater. Sci. Eng. A 640, 454 (2015)

Y.C. Xin, R. Hong, B. Feng, H.H. Yu, Y. Wu, Q. Liu, Mater. Sci. Eng. A 640, 210 (2015)

M. Asgari, F. Fereshteh-Saniee, T. Nonferr. Metal. Soc. 26, 1276 (2016)

Y.F. Chai, Y. Song, B. Jiang, J. Fu, Z.T. Jiang, Q.S. Yang, H.R. Sheng, G.S. Huang, D.F. Zhang, F.S. Pan, J. Magnes. Alloy. 7, 545 (2019)

W. Habila, H. Azzeddine, B. Mehdi, K. Tirsatine, T. Baudin, A.L. Helbert, F. Brisset, S. Gautrot, M.-H. Mathon, D. Bradai, Mater. Charact. 147, 242 (2019)

T. Wang, Y.L. Wang, L.P. Bian, Q.X. Huang, Mater. Sci. Eng. A 765, 138318 (2019)

L. Chen, J.W. Tang, G.Q. Zhao, C.S. Zhang, X.R. Chu, J. Mater. Process. Tech. 258, 165 (2018)

J.W. Tang, L. Chen, G.Q. Zhao, C.S. Zhang, L. Sun, J. Magnes. Alloy. 8, 654 (2020)

V.P. Singh, S.K. Patel, A. Ranjan, B. Kuriachen, J. Mater. Res. Technol. 9, 6217 (2020)

S.K. Raval, K.B. Judal, Mater. Today Proc. 22, 2665 (2020)

J.J. He, B. Jiang, H.M. Xie, Z.T. Jiang, B. Liu, F.S. Pan, Mater. Sci. Eng. A 675, 76 (2016)

Q.H. Wang, B. Jiang, Y.F. Chai, B. Liu, S.X. Ma, J. Xu, F.S. Pan, Mater. Sci. Eng. A 673, 606 (2016)

F.S. Pan, Q.H. Wang, B. Jiang, J.J. He, Y.F. Chai, J. Xu, Mater. Sci. Eng. A 655, 339 (2016)

F. Li, H.W. Jiang, Q. Chen, Y. Liu, Int. J. Adv. Manuf. Tech. 90, 73 (2017)

Y.P. Wang, F. Li, W.Y. Shi, X.W. Li, W.B. Fang, J. Mater. Eng. Perform. 28, 3551 (2019)

Y. Wang, F. Li, N. Bian, X.M. Xiao, Mater. Sci. Eng. A 818, 141366 (2021)

J. Xu, J.F. Song, B. Jiang, J.J. He, Q.H. Wang, B. Liu, G.S. Huang, F.S. Pan, Mater. Sci. Eng. A 706, 172 (2017)

W.T. Jia, S. Xu, Q.C. Le, L. Fu, L.F. Ma, Y. Tang, Mater. Design 106, 120 (2016)

A. Rudnytskyj, P. Simon, M. Jech, C. Gachot, Mater. Design 190, 108568 (2020)

J.W. Tang, L. Chen, G.Q. Zhao, C.S. Zhang, J.Q. Yu, J. Alloy. Compd. 784, 727 (2019)

W.B. Lee, K.S. Bang, S.B. Jung, J. Alloy. Compd. 390, 212 (2005)

M. Grujicic, G. Arakere, H.V. Yalavarthy, T. He, C.F. Yen, B.A. Cheeseman, J. Mater. Eng. Perform. 19, 672 (2010)

V. Firouzdor, S. Kou, Metall. Mater. Trans. A 41, 3238 (2010)

C.C. Hsieh, M.S. Shi, W. Wu, Met. Mater. Int. 18, 1 (2012)

Acknowledgements

This paper was supported by the Natural Science Foundation of Heilongjiang Province (LH2019E056) and the Fundamental Research Foundation for Universities of Heilongjiang Province (LGYC2018JQ011)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors indicate that they have no financial relationship with the organization that sponsored the research. And the authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gao, L., Li, F., Wang, Y. et al. Fabrication and Interface Structural Behavior of Mg/Al Thickness-Oriented Bonding Sheet via Direct Extrusion. Met. Mater. Int. 28, 1960–1970 (2022). https://doi.org/10.1007/s12540-021-01077-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-021-01077-5