Abstract

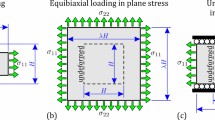

In this study, a mathematical analysis based on the slab method is used to drive a formula to calculate the average hydrostatic pressure in the compressive stage of the HPT process. The analytical method used here leads to a relationship for describing the average hydrostatic pressure as a function of the material shear strength, sample volume, cavity volume and force. Based on the results obtained and by employing the Sturm’s theorem for polynomials, a general expression for the minimum force required to start the deformation of the material under compressive force and creation of flash is developed. The analytical results were confirmed by carrying out some experiments by using commercial pure aluminum and copper as test materials. The experimental results showed good congruence with the analytical calculations. The most important outcome of this analysis is that with an appropriate selection of the sample volume, considering the capacity of the HPT press facility and the proper choice of the die cavity volume, favorable average hydrostatic pressure, necessary for the purpose of application can be achieved.

Graphic Abstract

Similar content being viewed by others

Abbreviations

- F or F total :

-

Magnitude of the compressive force applied in the HPT process

- A initial :

-

Initial contact area of the material and the die

- A final :

-

Final contact area of the material and the die

- \(\bar{\sigma }\) :

-

Equivalent stress

- \(\bar{\varepsilon }\) :

-

Equivalent strain

- k :

-

Material’s shear strength

- τ rz, τ rɵ and τ zɵ :

-

Shear stress components in cylindrical coordinate

- σ r, σ ɵ and σ z :

-

Normal stress components in cylindrical coordinate

- \(m\) :

-

Constant friction factor

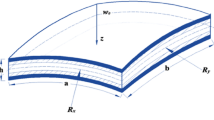

- R i :

-

Die cavity radius

- R f :

-

Flash material radius

- t :

-

Thickness of the flash material

- σ H :

-

Hydrostatic pressure

- \(\widetilde{{\sigma_{H} }}\) :

-

Average hydrostatic pressure in cavity zone

- V s :

-

Sample volume

- V c :

-

Cavity volume

- V critical :

-

Critical sample volume

- F cavityy and F flash :

-

Applied force to the material in the cavity zone and the flash material respectively

References

A.P. Zhilyaev, T.G. Langdon, Prog. Mater Sci. 53, 893–979 (2008)

P.W. Bridgman, J. Appl. Phys. 14, 273–283 (1943)

H. Ataei, M. Shahbaz, H. S. Kim, N. Pardis. Met. Mater. Int. (2020). https://doi.org/10.1007/s12540-020-00742-5

N. Pardis, R. Ebrahimi, Mater. Sci. Eng. A 527, 355–360 (2009)

R.K. Islamgaliev, N.F. Yunusova, I.N. Sabirov, A.V. Sergueeva, R.Z. Valiev, Mater. Sci. Eng. A 319–321, 877–881 (2001)

Y.H. Zhao, Y.T. Zhu, X.Z. Liao, Z. Horita, T.G. Langdon, Mater. Sci. Eng. A 463, 22–26 (2007)

A. Kilmametov, R. Kulagin, A. Mazilkin, S. Seils, T. Boll, M. Heilmaier, H. Hahn, Scr. Mater. 158, 29–33 (2019)

M. Gajdics, T. Spassov, V.K. Kis, E. Schafler, Á. Révész, Int. J. Hydrogen Energy 45, 7917–7928 (2020)

K. Edalati, Z. Horita, Scr. Mater. 63, 174–177 (2010)

R.B. Figueiredo, M.T.P. Aguilar, P.R. Cetlin, T.G. Langdon, J. Mater. Sci. 47, 7807–7814 (2012)

D.J. Lee, E.Y. Yoon, D. Ahn, B.H. Park, H.W. Park, L.J. Park, Y. Estrin, H.S. Kim, Acta Mater. 76, 281–293 (2014)

M.V. Degtyarev, T.I. Chashchukhina, L.M. Voronova, A.M. Patselov, P.V. Pilyugin, Acta Mater. 55, 6039–6050 (2007)

J.J. Jonas, C. Ghosh, L.S. Toth, Mater. Sci. Eng. A 607, 530–535 (2014)

S. Khoddam, P.D. Hodgson, A. Zarei-Hanzaki, L.Y. Foon, Mater. Des. 99, 335–340 (2016)

S. Khoddam, Mater. Sci. Eng. A 683, 256–263 (2017)

K. Edalati, D.J. Lee, T. Nagaoka, M. Arita, H.S. Kim, Z. Horita, R. Pippan, Mater. Trans. 57, 533–538 (2016)

V.I. Levitas, Mater. Trans. 60, 1294–1301 (2019)

B. Efros, V. Pilyugin, A. Patselov, S. Gladkovskii, N. Efros, L. Loladze, V. Varyukhin, Mater. Sci. Eng. A 503, 114–117 (2009)

P.W. Bridgman, I. Simon, J. Appl. Phys. 24, 405–413 (1953)

E.R. Lippincott, H.C. Duecker, Science 144, 1119–1121 (1964)

P. Henrique, R. Pereira, R.B. Figueiredo, Mater. Trans. 60, 1139–1150 (2019)

M. Kamrani, V.I. Levitas, B. Feng, Mater. Sci. Eng. A 705, 219–230 (2017)

W. Wang, Y. Song, D.S. Gao, E.Y. Yoon, D.J. Lee, C.S. Lee, H.S. Kim, Met. Mater. Int. 19, 1021–1027 (2013)

Y. Song, W. Wang, D.S. Gao, E.Y. Yoon, D.J. Lee, C.S. Lee, H.S. Kim, J. Mater. Sci. 48, 4698–4704 (2013)

J.M. Thomas, Natl. Math. Mag 15, 391–394 (1941)

Q.I. Rahman, G. Schmeisser, Analytic Theory of Polynomials, London Mathematical Society Monographs. New Series. 26 (Oxford University Press, Oxford, 2002). pp. 335–339

R.M. Caddlle, W.F. Hsoford, Metals Forming: Metallurgy and Mechanics (Cambridge University Press, New York, 2007), pp. 87–88

Acknowledgements

The authors appreciate Shiraz University for the financial support (Grant numbers of 97-GR-ENG-15 and 96-GRD1M1818) and research facilities used in this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1

According to the Strum’s theorem for a cubic free polynomial, P, the number of distinct real roots between \(\left( {a,b} \right]\) can be determined by sign changes of the terms of the Sturm’s sequence of P, at a and b. Sturm’s sequence for P is of the following form:

where \(rem\left( {P_{i - 1} ,P_{i} } \right)\) denotes the reminder of the division of polynomial \(P_{i - 1}\) by \(P_{i}\).

By combining Eqs. (10) and (12), the force can be restated as follows:

Considering \(x^{2} = {\raise0.7ex\hbox{$1$} \!\mathord{\left/ {\vphantom {1 t}}\right.\kern-0pt} \!\lower0.7ex\hbox{$t$}}\), Eq. (14) becomes:

where

\(\alpha\) and \(\beta\) always have positive values and \(\psi\) always has negative values, sign of \(\gamma\) depends on the value of F.

On the other hand, the critical value for t is as such:

Therefore, the acceptable range for t is \(0 \le t \le t_{cri}\).

Based on the definition of \(x\), the critical value of \(x\) is:

And the acceptable range for \(x\) is \(x \ge x_{cri}\).

The aim is to set values for \(F\) to make Eq. (15) have a root in the acceptable range of \(x\) which is \(\left( {x_{cri} ,\infty } \right]\). Forming the Strum’s chain for polynomial appeared in Eq. (15) gives the following terms:

Signs of these polynomials at \(x \to \infty\) are determined by sign of their leading coefficient, except for \(p_{4}\) which for a given material and \(R_{i}\), its sign depends on the value of F; therefore, \(sign_{\infty } = \left( { + , + , - , - , \pm } \right)\).

By evaluating \(p_{1}\) and \(p_{3}\), it will be obvious that these terms are always positive and negative respectively, so the sign of polynomials at \(x_{cr}\) would be

Acceptable range for \(F\) is one which makes:

where \(\left\|sign_{i} \right\|\) denotes the number of sign changes of polynomials at \(x = x_{i}\), for example \(\left\|sign_{\infty }\right\|\) equals 1 or 2, depending on the sign of \(p_{4}\). As \(p_{3}\) is always negative and the sign of \(p_{4}\) does not depend on \(x\), thus the sign of \(p_{4}\) has no effect on \(\left\|sign_{{x_{cr} }} \right\| - \left\|sign_{\infty }\right\|\) therefor only signs of \(p_{0}\) and \(p_{2}\) must be considered. Among four possible situations for signs \(p_{0}\) and \(p_{2}\) only those two with \(p_{0} \le 0\) result in a condition stated in Eq. (20).

\(p_{0} \le 0\) Corresponds to:

and \(p_{2} \ge 0\) corresponds to:

But it can easily be shown that, \(\frac{3}{5}\beta x^{2} + \psi \le \alpha x^{5} + \beta x^{2} + \psi\). Therefore, the intersection of the inequalities of Eqs. (21) and (22) is null. On the other hand, the intersection of \(p_{0} \ge 0\) and \(p_{2} \le 0\) results in:

Substituting α, β and ψ from Eq. (16) with Eq. (23) and considering \(x = \sqrt {\frac{{\pi R_{i}^{2} }}{{V_{s} - V_{c} }}}\), F becomes:

Appendix 2

Based on the geometrical considerations, the ideal imposed strain would be:

where:

Using the von Mises equivalent strain, one obtains the effective strain to be:

Replacing \(\bar{\varepsilon }\) in the Holloman equation, \(\bar{\sigma }\) would be:

where K is the strength coefficient.

Based on the von Mises yield criterion, the shear strength (k) would be:

where \(t_{0}\) is the initial and \(t\) is the final gap between the dies which is equal to flash thickness. While \(t\) is measured directly after the compression of the disks, the value of \(t_{0}\) can be calculated as follow:

Rearranging this formula in terms of volume, one may obtain:

Here \(V_{c}\) denotes the closed cavity volume which is the volume entrapped between the cavities when two dies are tightly placed on each other without any gap; \(V_{s}\) represents the volume of the sample and \(R_{i}\) represents the diameter of the cavity. Therefore, it can be seen that samples with different volumes experience different strains hence the shear strength would be different from a sample to another.

Based on the discussions made in [27] for the slab analysis of metal forming processes the material is taken to be rigid-perfectly plastic, which means, a) the elastic strains are neglected compared to plastic strains and b) the work hardening of material is ignored. While the former is completely logical and may not introduce any significant errors, the latter may cause ambiguities in the calculations. One of the best techniques to resolve such ambiguities is to consider the average flow stress as the material property in the equations. Similar method is used in this study where the calculated values of k are averaged and the average value is employed in analytical calculations.

Rights and permissions

About this article

Cite this article

Hadi, S., Rahimzadeh lotfabad, F., Paydar, M.H. et al. New Mathematical Stress Analysis in the Compressive Stage of the High-Pressure Torsion Process. Met. Mater. Int. 27, 2947–2956 (2021). https://doi.org/10.1007/s12540-020-00881-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00881-9