Abstract

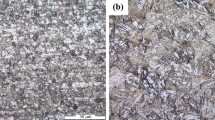

This study aims to investigate the influence of nugget diameter on tensile-shear and fatigue properties of the dissimilar resistance spot-welded joints of interstitial free and high strength niobium microalloyed steel sheets. The spot-weldings are done at currents of 7 kA and 9 kA at welding time of 300 ms with electrode force of 2.6 kN. Fatigue tests are done at different load amplitudes, considering the maximum tensile-shear load bearing capacity of the joints. The tests are interrupted before the final failure to understand the crack initiation and propagation paths. The study is supplemented by the microstructural and detailed fractographic analyses. The results indicated that the fatigue strength of the spot-welds increased with a decrease in nugget diameter. This could be attributed to the higher microhardness of heat affected zone (HAZ), presence of compressive residual stress and lower variation in thickness reduction on the IF steel side, welded at 7 kA. However, the tensile-shear load bearing capacity of the spot-welds increased with increase in the nugget diameter. The failure of the spot-welded joint under static loading initiates from the HAZ/base metal interface of the IF steel side. Nevertheless, under cyclic loading crack initiates from the notch root at the interface of two sheets lying in the HAZ of IF steel side. Fractographic investigations indicate intergranular fracture features in combination with striations, secondary cracks on the IF steel side under cyclic loading. Fracture surfaces of the specimens failed under static loading shows however, shear dimples on the IF steel side.

Graphic Abstract

Similar content being viewed by others

References

R. Rana, S.B. Singh, Automotive Steels: Design, Metallurgy, Processing and Applications, 1st edn. (Woodhead Publishing, Sawston, 2016), pp. 1–478

S. Acharya, K.K. Ray, Assessment of tensile properties of spot welds using shear punch test. Mater. Sci. Eng. A 565, 405–413 (2013). https://doi.org/10.1016/j.msea.2012.12.068

M. Pouranvari, S.P.H. Marashi, Failure mode transition in AHSS resistance spot welds. Part I. Controlling factors. Mater. Sci. Eng. A 528, 8337–8343 (2011). https://doi.org/10.1016/j.msea.2011.08.017

I. Hajiannia, M. Shamanian, M. Atapour, R. Ashiri, Evaluation of weldability and mechanical properties in resistance spot welding of ultrahigh-strength TRIP1100 steel. SAE Int. J. Mater. Manf. 12, 5–18 (2018). https://doi.org/10.4271/05-12-01-0001

M. Pouranvari, S.P.H. Marashi, Critical review of automotive steels spot welding: process, structure and properties. Sci. Technol. Weld. Join. 18, 361–403 (2013). https://doi.org/10.1179/1362171813Y.0000000120

F. Rossillon, A. Galtier, J.L. Robert, M. Duchet, A. Lens, H. Oikawa, Effect of welding cycle on the fatigue behaviour of resistance spot welded dual phase steels. Weld. World 52, 30–41 (2008). https://doi.org/10.1007/BF03266680

M.I. Khan, M.L. Kuntz, Y. Zhou, Effects of weld microstructure on static and impact performance of resistance spot welded joints in advanced high strength steels. Sci. Technol. Weld. Join. 13, 294–304 (2008). https://doi.org/10.1179/174329308X271733

S. Daneshpour, S. Riekehr, M. Koçak, C.H.J. Gerritsen, Mechanical and fatigue behaviour of laser and resistance spot welds in advanced high strength steels. Sci. Technol. Weld. Join. 14, 20–25 (2008). https://doi.org/10.1179/136217108x336298

T.K. Pal, K. Chattopadhyay, Resistance spot weldability and high cycle fatigue behaviour of martensitic (M190) steel sheet. Fatigue Fract. Eng. Mater. Struct. 34, 46–52 (2011). https://doi.org/10.1111/j.1460-2695.2010.01489.x

H.M. Rao, J. Kang, L. Shi, D.R. Sigler, B.E. Carlson, E ff ect of specimen con fi guration on fatigue properties of dissimilar aluminum to steel resistance spot welds. Int. J. Fatigue 116, 13–21 (2018). https://doi.org/10.1016/j.ijfatigue.2018.06.009

R.W. Rathbun, D.K. Matlock, J.G. Speer, Fatigue behavior of spot welded high-strength sheet steels. Weld. J. 82, 207–218 (2003)

Y. Zhang, D. Taylor, Sheet thickness effect of spot welds based on crack propagation. Eng. Fract. Mech. 67, 55–63 (2000). https://doi.org/10.1016/S0013-7944(00)00029-1

P. Banerjee, R. Sarkar, T.K. Pal, M. Shome, Effect of nugget size and notch geometry on the high cycle fatigue performance of resistance spot welded DP590 steel sheets. J. Mater. Process. Technol. 238, 226–243 (2016). https://doi.org/10.1016/j.jmatprotec.2016.07.023

X. Long, S.K. Khanna, Fatigue properties and failure characterization of spot welded high strength steel sheet. Int. J. Fatigue 29, 879–886 (2007). https://doi.org/10.1016/j.ijfatigue.2006.08.003

S. Ghosh, T.K. Pal, Combined effect of strength & sheet thickness on fatigue behaviour of resistance spot welded joint. Fatigue Fract. Eng. Mater. Struct. 33, 562–574 (2010). https://doi.org/10.1111/j.1460-2695.2010.01467.x

J.H. Ordoñez, R.R. Ambriz, C. García, G. Plascencia, D. Jaramillo, Overloading effect on the fatigue strength in resistance spot welding joints of a DP980 steel. Int. J. Fatigue 121, 163–171 (2019). https://doi.org/10.1016/j.ijfatigue.2018.12.026

H. Zhang, J. Senkara, Resistance Welding Fundamentals and Applications, 2nd edn. (CRC Press, Boca Raton, 2011), pp. 1–452

M. Pouranvari, A. Abedi, P. Marashi, M. Goodarzi, Effect of expulsion on peak load and energy absorption of low carbon steel resistance spot welds. Sci. Technol. Weld. Join. 13, 39–43 (2008). https://doi.org/10.1179/174329307X249342

M. Pouranvari, S.P.H. Marashi, Factors affecting mechanical properties of resistance spot welds. Mater. Sci. Technol. 26, 1137–1144 (2010). https://doi.org/10.1179/174328409X459301

S. Salimi Beni, M. Atapour, M.R. Salmani, R. Ashiri, Resistance spot welding metallurgy of thin sheets of zinc-coated interstitial-free steel. Meta. Mater. Trans A. 50, 2218–2234 (2019). https://doi.org/10.1007/s11661-019-05146-8

B. Wang, Q.Q. Duan, G. Yao, J.C. Pang, Z.F. Zhang, L. Wang, X.W. Li, Fatigue fracture behaviour of spot welded B1500HS steel under tensile-shear load. Fatigue Fract. Eng. Mater. Struct. 38, 914–922 (2015). https://doi.org/10.1111/ffe.12289

M. Pouranvari, S. Sobhani, F. Goodarzi, Resistance spot welding of MS1200 martensitic advanced high strength steel: microstructure-properties relationship. J. Manuf. Process. 31, 867–874 (2018). https://doi.org/10.1016/j.jmapro.2018.01.009

M.S. Khan, S.D. Bhole, D.L. Chen, E. Biro, G. Boudreau, J. van Deventer, Welding behaviour, microstructure and mechanical properties of dissimilar resistance spot welds between galvannealed HSLA350 and DP600 steels. Sci. Technol. Weld. Join. 14, 616–625 (2009). https://doi.org/10.1179/136217109X12464549883295

G. Krauss, S.W. Thompson, Ferritic microstructures in continuously cooled low- and ultralow-carbon steels. ISIJ Int. 35, 937–945 (1995). https://doi.org/10.2355/isijinternational.35.937

J.K. Hong, D.H. Bae, I.S. Sohn, Assessing effects of residual stress on the fatigue strength of spot welds. Weld. J. 82, 18–23 (2003)

M.N. James, Intergranular crack paths during fatigue in interstitial-free steels. Eng. Fract. Mech. 77, 1998–2007 (2010). https://doi.org/10.1016/j.engfracmech.2009.12.006

Acknowledgements

The authors would like to acknowledge and thank Scientific Services, Advanced Material Characterization Lab and Material Welding and Joining Lab of Tata Steel Limited, Jamshedpur, India and the Management of National Institute of Technology, Rourkela.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Janardhan, G., Kishore, K., Mukhopadhyay, G. et al. Fatigue Properties of Resistance Spot Welded Dissimilar Interstitial-Free and High Strength Micro-Alloyed Steel Sheets. Met. Mater. Int. 27, 3432–3448 (2021). https://doi.org/10.1007/s12540-020-00678-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00678-w