Abstract

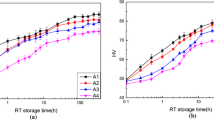

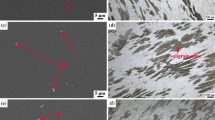

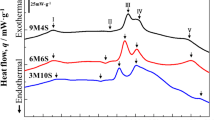

The effect of Cu contents on nanocluster formation and the two-step aging behavior of Al–Mg–Si alloys was studied based on hardness, DSC and TEM results. The activation energies for the formation of Cluster (1) were 61.6, 70.3 and 92.9 kJ/mol for Cu-free, 1Cu (0.1 mass% Cu-added) and 3Cu (0.3 mass% Cu-added), respectively. It was confirmed that hardness increased slowly with increasing Cu content during natural aging for 3.6 ks. These results suggest that the formation kinetics of Cluster (1) decrease due to the vacancy trapping phenomenon, because of the strong interactions of the Cu-vacancies. Meanwhile, the effect of the formation of nanoclusters by Cu addition on the two-step aging behavior at 170 °C during natural aging was analyzed. Hardness at the initial stage of the two-step aging increased with increasing Cu contents. This was caused by the suppression of Cluster (1) formation during natural aging by the Cu additions. Based on TEM results, at the peak hardness of the two-step aging, the number density of precipitates was increased by increasing Cu contents, due to the suppression of nanocluster formation during natural aging.

Graphic Abstract

Nanocluster formation behavior by DSC, two-step aging behavior based on hardness results and precipitation observation at the peak hardness using TEM. Two types of nanoclusters were analyzed using DSC based on Gaussian function method in Al–Mg–Si alloys. The formation of nanoclusters is suppressed during natural aging by Cu additions. Also, the hardness is clearly increased by Cu addition at the initial stage of two-step aging at 170 °C after natural aging for 3.6 ks. Based on TEM results, the number density of precipitates was increased by increasing Cu contents at the peak hardness of the two-step aging due to the suppression of nanocluster formation during natural aging.

Similar content being viewed by others

Change history

09 January 2020

A Correction to this paper has been published: https://doi.org/10.1007/s12540-019-00607-6

References

J. Hirsch, Trans. Nonferrous Metals Soc. China 24, 1995 (2014)

J. Banhart, Int. J. Veh. Design 37, 114 (2005)

G.A. Edwards, K. Stiller, G.L. Dunlop, M.J. Couper, Acta Mater. 46, 3893 (1998)

K. Matsuda, Y. Sakaguchi, Y. Miyata, Y. Uetani, T. Sato, A. Kamio, S. Ikeno, J. Mater. Sci. 35, 179 (2000)

C.D. Marioara, S.J. Andersen, H.W. Zandbergen, R. Holmestad, Metall. Mater. Trans. A 36A, 691 (2005)

C.D. Marioara, H. Nordmark, S.J. Andersen, R. Holmestad, J. Mater. Sci. 41, 471 (2006)

A. Serizawa, S. Hirosawa, T. Sato, Mater. Sci. Forum 519–521, 245 (2006)

J. Im, J. Jeon, M. Song, S. Hong, J. Kim, Metals Mater. Int. 25, 860 (2019)

E. Kwon, K. Woo, S. Kim, D. Kang, K. Lee, J. Jeon, Metals Mater. Int. 16, 701 (2010)

J. Man, L. Jing, S.G. Jie, J. Alloys Compd. 437, 146 (2007)

L. Ding, Z. Jia, Z. Zhang, R.E. Sanders, Q. Liu, G. Yang, Mater. Sci. Eng. A 627, 119 (2015)

C.D. Marioara, S.J. Andersen, T.N. Stene, H. Hasting, J. Walmsley, A.T.J. Van Helvoort, R. Holmestad, Philos. Magazine 87, 3385 (2007)

C. Cayron, L. Sagalowicz, O. Beffort, P.A. Buffat, Philos. Magazine A 79, 2833 (1999)

K. Matsuda, Y. Uetani, T. Sato, S. Ikeno, Metall. Mater. Trans. A 32, 1293 (2001)

W.F. Miao, D.E. Laughlin, Scr. Mater. 40, 873 (1999)

S.D. Dumolt, D.E. Laughlin, J.C. Williams, Scr. Metall. 18, 1347 (1984)

A. Gaber, A.M. Ali, K. Matsuda, T. Kawabata, T. Yamazaki, S. Ikeno, J. Alloys Compd. 432, 149 (2007)

A. Gaber, M.A. Gaffar, M.S. Mostafa, E.F. Abo Zeid, J. Alloys Compd. 429, 167 (2007)

J. Kim, C.D. Marioara, R. Holmestad, E. Kobayashi, T. Sato, Mater. Sci. Eng. A 560, 154 (2013)

J. Kim, S. Kim, E. Kobayashi, T. Sato, Mater. Trans. 55, 768 (2014)

K. Matsuda, T. Naoi, K. Fujii, Y. Uetani, T. Sato, A. Kamio, Mater. Sci. Eng. A 262, 232 (1999)

Y. Aruga, M. Kozuka, Y. Takaki, T. Sato, Mater. Sci. Eng. A 631, 86 (2015)

A.K. Gupta, D.J. Lloyd, Metall. Mater. Trans. A 30A, 879 (1999)

L. Cao, P.A. Rometsch, M.J. Couper, Mater. Sci. Eng. A 559, 257 (2013)

R.K.W. Marceau, A. de Vaucorbeil, G. Sha, S.P. Ringer, W.J. Poole, Acta Mater. 61, 7285 (2013)

S. Özbilen, H.M. Flower, Acta Metall. 37, 2993 (1989)

A. Serizawa, S. Hirosawa, T. Sato, Metall. Mater. Trans. A 39A, 243 (2008)

Y. Du, Y.A. Chang, B. Huang, W. Gong, Z. Jin, H. Xu, Z. Yuan, Y. Liu, Y. He, F.Y. Xie, Mater. Sci. Eng. A 363, 140 (2003)

H. Kimura, R.R. Hasiguti, Acta Metall. 9, 1076 (1961)

S. Pogatscher, M. Werinos, H. Antrekowitsch, P.J. Uggowitzer, Mater. Sci. Forum 794–796, 1008 (2014)

C. Wolverton, Acta Mater. 55, 5867 (2007)

O. Melikhova, J. Kuriplach, J. Čížek, I. Procházka, Appl. Surf. Sci. 252, 3285 (2006)

P. Lang, Y.V. Shan, E. Kozeschnik, Mater. Sci. Forum 794–796, 963 (2014)

P. Lang, T. Weisz, M.R. Ahmadi, E. Povoden-Karadeniz, A. Falahati, E. Kozeschnik, Adv. Mater. Res. 922, 406 (2014)

D.W. Pashley, M.H. Jacobs, J.T. Vietz, Philos. Magazine 16, 51 (1967)

K. Yamada, T. Sato, A. Kamio, Mater. Sci. Forum 331–337, 669 (2000)

J. Kim, E. Kobayashi, T. Sato, Mater. Trans. 56, 1771 (2015)

S. Pogatscher, H. Antrekowitsch, H. Leitner, T. Ebner, P.J. Uggowitzer, Acta Mater. 59, 3352 (2011)

Acknowledgements

This work was supported by the Development of hot/warm forming-heat treatment integrated process for high strength aluminum alloy (PEO19422) of the Korea Institute of Industrial Technology. The authors are grateful to UACJ Corp. for the material supply.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original version of this article was revised: fourth author name was updated.

Rights and permissions

About this article

Cite this article

Song, M., Kim, I., Kim, J. et al. Effect of Cu Contents on Nanocluster Formation and Two-Step Aging Behavior in Al–Mg–Si Alloys. Met. Mater. Int. 27, 1374–1381 (2021). https://doi.org/10.1007/s12540-019-00540-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00540-8