Abstract

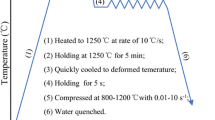

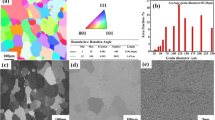

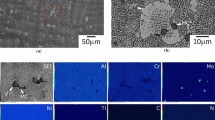

The hot deformation behavior of a Ni-Cu alloy was studied using hot compression testing in the temperature range of 950 °C–1150 °C and at strain rates of 0.001 s−1-1 s−1. Flow curves at low strain rates, up to 0.01 s−1, were typical of DRX characterized by a single peak, while at higher strain rates, the typical form of a DRX flow curve was not observed. The power-law constitutive equation was used to correlate flow stress to strain rate and temperature, and the apparent activation energy of hot deformation was determined to be about 462.4 kJ/mol. The peak strain and stress were related to the Zener-Hollomon parameter and the modeling formula was proposed. The dependence of flow stress to the Z changed at ln Z=38.5, which was considered to be a critical condition for the change in the mechanism of dynamic recrystallization. The efficiency of power dissipation was determined to be between 10–35 percent at different deformation conditions. According to the dynamic material model, stable flow was predicted for the studied temperature and strain rate ranges. Highly serrated grain boundaries at low strain rates were considered to be a reason for the occurrence of continuous dynamic recrystallization. On the contrary, at high strain rates, equiaxed grain structure was attributed to the typical discontinuous dynamic recrystallization.

Similar content being viewed by others

References

G. K. Dey, R. Tewari, P. Rao, S. L. Wadekar, and P. Mukhopadhyay, Met. Mater. Trans. A 24, 2709 (1993).

G. T. Gray III, S. R. Chen, and K. S. Vecchio, Met. Mater. Trans. A 30, 1235 (1999).

A. Dehghan-Manshadi, M. R. Barnett, and P. D. Hodgson, Met. Mater. Trans. A 39, 1359 (2008).

G. R. Ebrahimi, H. Keshmiri, A. Momeni, and M. Mazinani, Mater. Sci. Eng. A 528, 7488 (2011).

L. Gavard, F. Montheillet, and J. L. Coze, Mater. Trans. JIM 41, 113 (2000).

S. Mandal, P. V. Sivaprasad, R. Dube, and B. Raj, Mater. Sci. Forum 550, 601 (2007).

A. Momeni, K. Dehghani, H. Keshmiri, and G. R. Ebrahimi, Mater. Sci. Eng. A 527, 1605 (2010).

A. Momeni, K. Dehghani, G. R. Ebrahimi, and H. Keshmiri, Metall. Mater. Trans. A 41, 2898 (2010).

A. Momeni, S. M. Abbasi, and A. Shokuhfar, Can. Metal. Quart. 4, 189 (2007).

E. V. Konopleva, M. Sauerborn, H. J. McQueen, N. D. Ryan, and R. G. Zaripova, Mater. Sci. Eng. A 234–236, 826 (1997).

H. J. McQueen, N. D. Ryan, R. Zaripova, and K. Farkhutdinov, Proc.37th Mechanical Working and Steel Processing, pp.883–888, Iron and Steel Inst. AIME, Warrendale (1996).

H. J. McQueen and W. Blum, Mater. Sci. Eng. A 290, 95 (2000).

B. Verlinden, J. Driver, I. Samajdar, and R. D. Doherty, Thermo-Mechanical Processing of Metallic Materials, p. 60, Pergamon (2007).

N. Srinivasan and Y. V. R. K. Prasad, Mater. Sci. Technol. 8, 206 (1992).

Y. V. R. K. Prasad and S. Sasidhara, Hot Working Guide: A Compendium of Processing Maps, pp.435–436, ASM International, Materials Park, OH (1997).

Q. Li, Y. B. Xu, Z. X. Lai, L.T. Shen, and Y. L. Bai, Mater. Sci. Eng. A 276, 250 (2000).

A. Momeni and K. Dehghani, Met. Mater. Int. 16, 843 (2010).

Y. V. R. K. Prasad, H. J. Gegel, S. M. Doraivelu, J. C. Malas, J. C. Morgan, L. A. Lark, and D. R. Barker, Metall. Trans. A 15, 1883 (1984).

R. Ebrahimi and A. Najafizadeh, Int. J. ISSI 1, 1 (2004).

H. Ziegler, Progress in Solid Mechanics, (eds. I.N. Sneedon and R. Hill), pp.63–193, John Wiley and Sons, New York (1963).

F. J. Humphreys and M. Hatherly, Recrystallisation and Related Annealing Phenomena, 2nd Ed., pp.418–421, Elsevier Ltd., London (2004).

P. Cizek and B. P. Wynne, Mater. Sci. Eng. A 230, 88 (1997).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ebrahimi, G.R., Momeni, A., Abbasi, S.M. et al. Constitutive analysis and processing map for hot working of a Ni-Cu alloy. Met. Mater. Int. 19, 11–17 (2013). https://doi.org/10.1007/s12540-013-1003-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-013-1003-8